A rotary stud conveying device

A conveying device and rotary technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of stud jamming, increase work cost, instability, etc., and achieve the effect of avoiding jamming and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

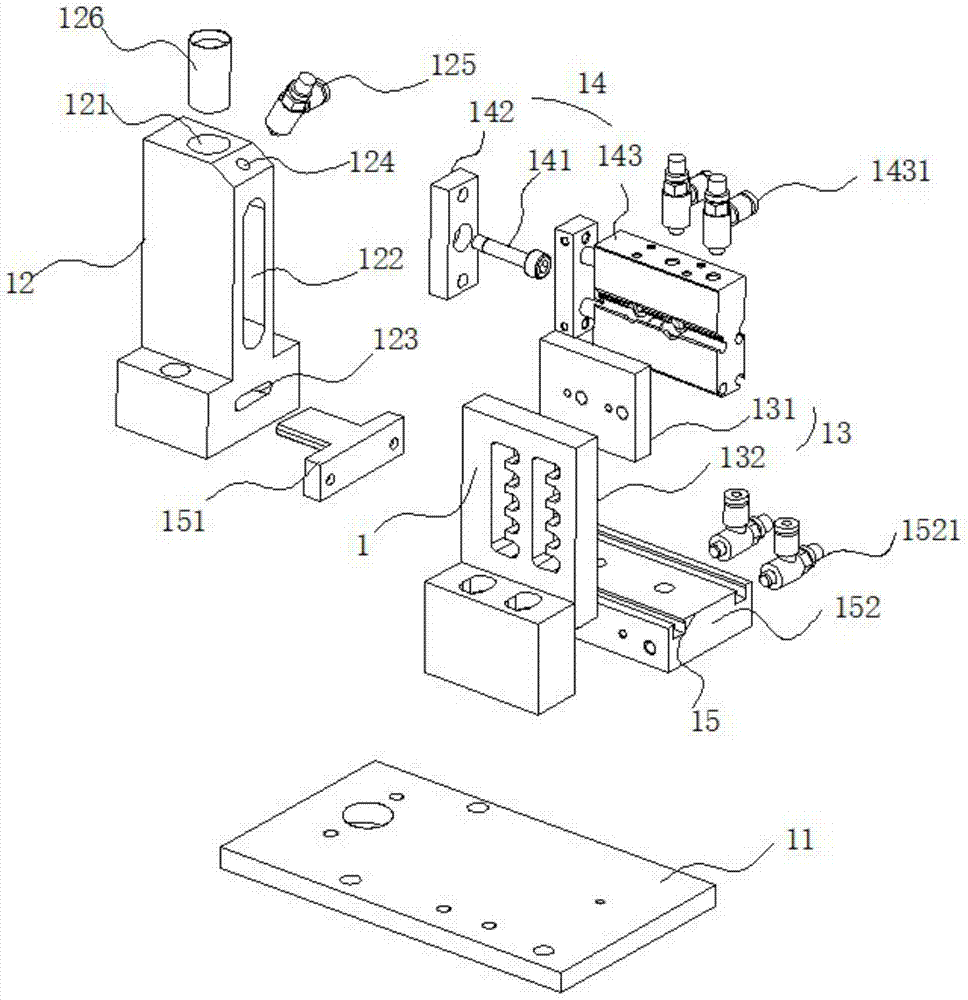

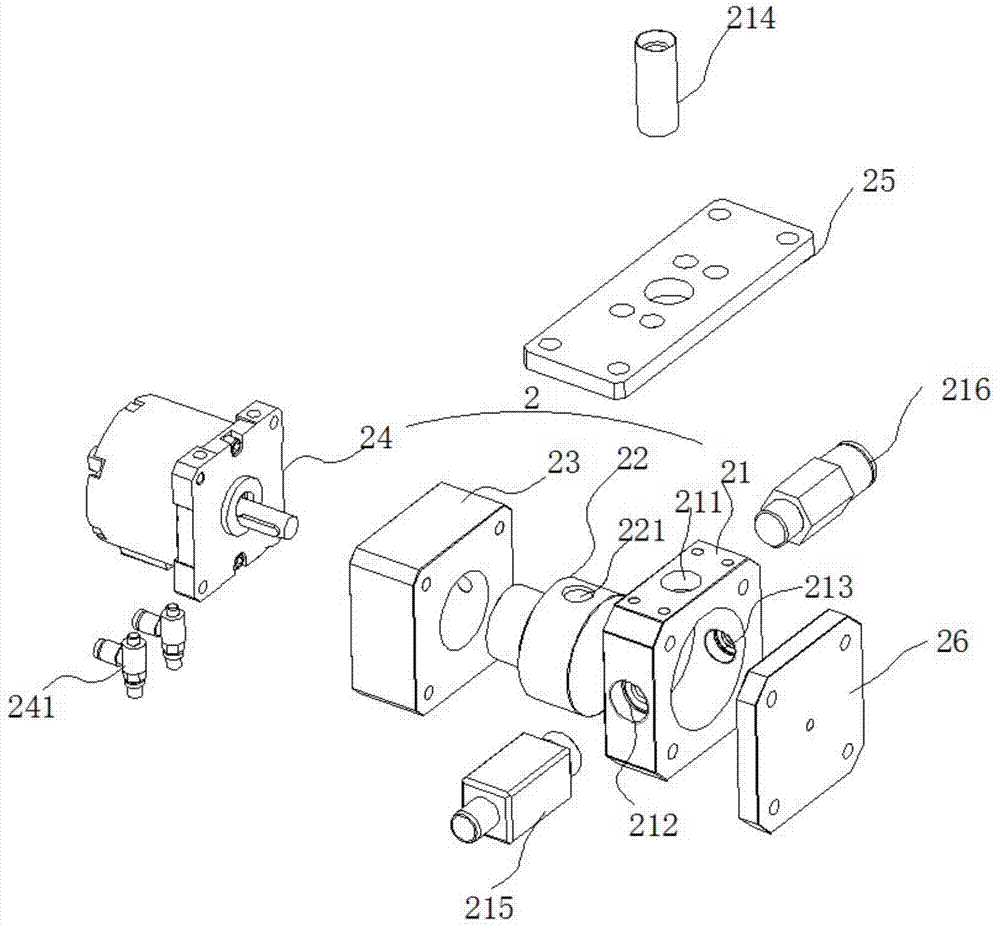

[0014] The rotary stud conveying device provided by the present invention includes a clamping limiting device 1 and a rotary propulsion device 2 located below the clamping limiting device 1 and connected to its output port.

[0015] see figure 1 , which is an exploded view of the clamping and limiting device of the present invention. The clamping and limiting device 1 includes a base 11 , a stud conveying block 12 , a position adjusting block 13 , a clamping device 14 and a limiting device 15 . The stud conveying block 12 is fixed on the base 11 by screws. The stud delivery block 12 is provided with a passage (not shown) for conveying studs; A clamping device socket 122 and a limiting device socket 123 are provided at the side end. The position adjusting block 13 is fixed on the base 11 by screws. The clamping device 14 is fixed on the position adjusting block 13 by screws, and the clamping device 14 is inserted into the channel periodically through the clamping device soc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com