Self-degradation rubber greening device

A rubber grass, self-degradation technology, applied in the field of slope greening installation, can solve the problems that rubber grass cannot be automatically degraded, natural environment damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

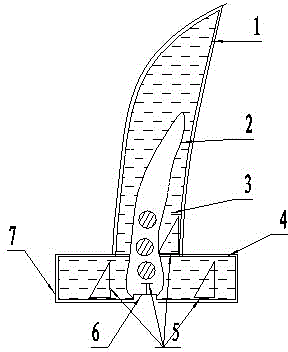

[0009] Below in conjunction with Fig. 1 describe in detail the specific work situation that the present invention proposes, figure 1 In the outer layer of rubber 7, a liquid storage bag 1 and a seed bag 2 are installed, and a degradation liquid 3 and a plastic nail 5 are housed in the liquid storage bag 1, and grass seeds and plastic nails 5 are housed in the seed bag 2, and the lower end of the seed bag 2 is connected with a The planting outlet 6, the base 4 is fixedly connected with the outer rubber 7.

[0010] Put the liquid storage bag 1 and the seed bag 2 into the outer rubber 7 and the base 4, when an external force acts on the outer rubber 7, the plastic nail 5 will break through the liquid storage bag 1, and the degradation solution 3 will enter the entire outer layer. In the layer of rubber 7, the outer layer of rubber 7 and the reservoir 1 and the seed capsule 2 are automatically degraded, and the seeds in the seed capsule 2 enter the soil through the planting outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com