Shake-up device

A ring and frame technology, applied in the field of pharmaceutical production equipment, can solve problems such as high labor intensity for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

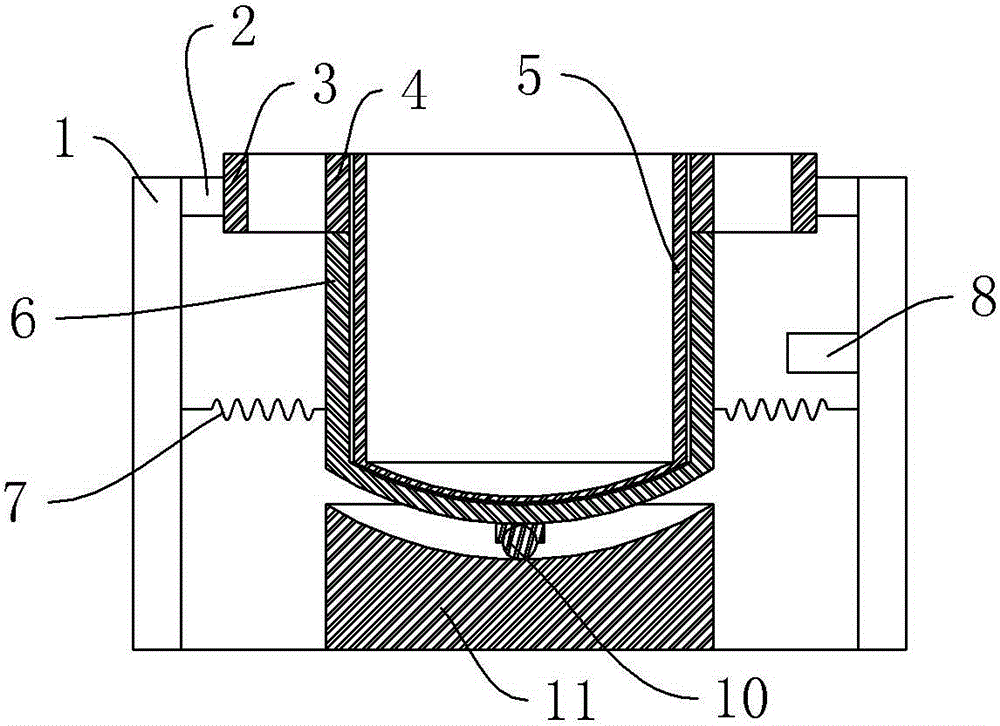

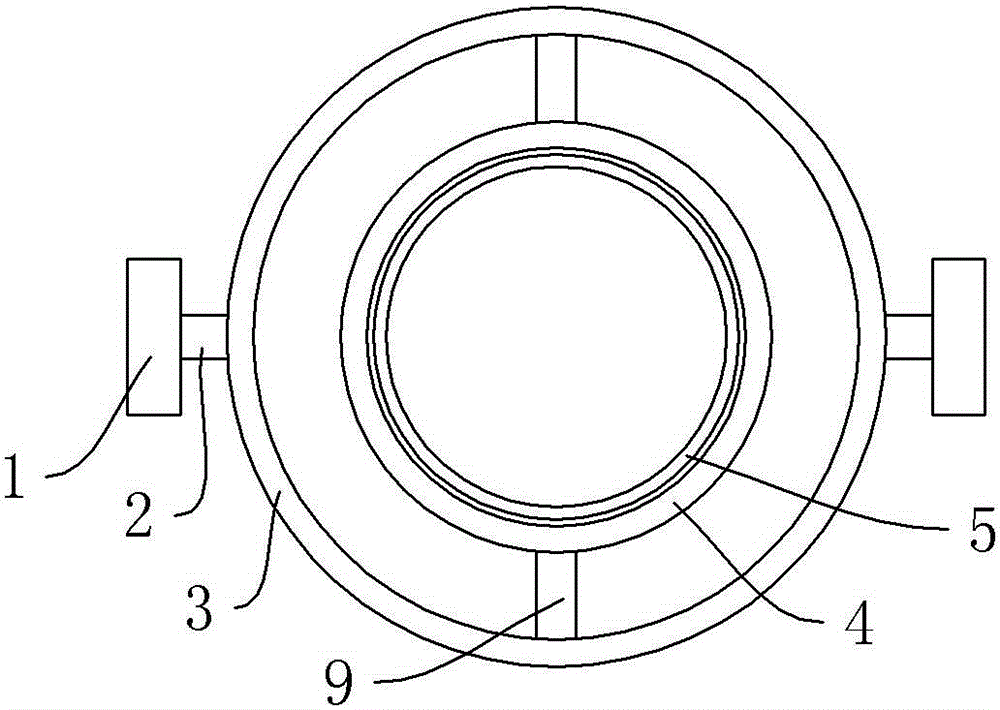

[0013] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

[0014] Among the figure: frame body 1, rotating shaft I2, first circular ring 3, second circular ring 4, inner barrel 5, shaking barrel 6, spring 7, electromagnet 8, rotating shaft II 9, universal ball bearing 10, support seat 11.

[0015] Such as figure 1 and figure 2 The shaking device shown includes a frame body 1 , a first ring 3 , a second ring 4 and a shaking bucket 6 . The first circular ring 3 is horizontally arranged on the top of the frame body 1, and the left and right sides of the first circular ring 3 are respectively provided with a rotating shaft I2, and the two rotating shafts I2 are coaxial, and the axis of the rotating shaft I2 passes through the first circular ring 3, the rotating shaft I2 is rotationally connected with the frame body 1. The second ring 4 is located inside the first ring 3 and arranged concentricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com