A large satellite frame painting turning device

A satellite and large-scale technology, which is applied in the field of large-scale satellite frame painting and turning devices, can solve the problems affecting the safety of large-scale satellite frames and hidden dangers of unsafe products, and achieves the effect of saving time and manpower, ensuring safety, and facilitating disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The paint spraying and turning device of the large satellite frame of the present invention will be described in further detail below in conjunction with the accompanying drawings of the specification.

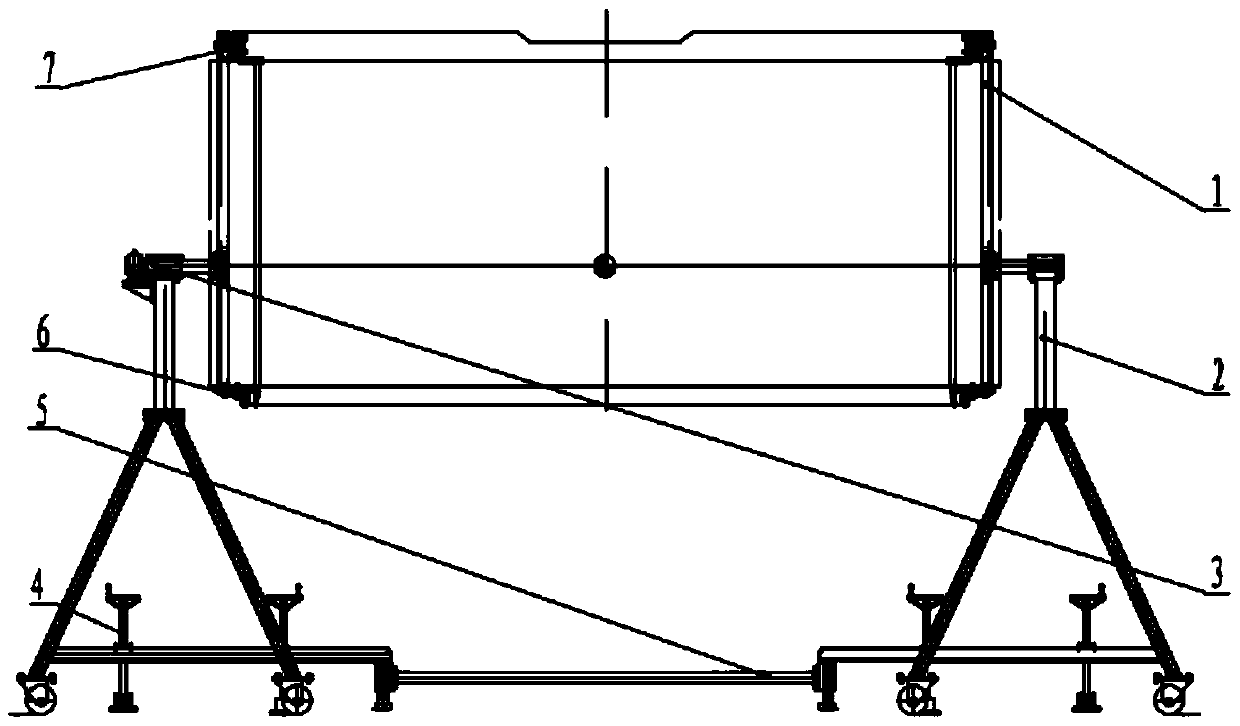

[0055] Figure 1(a) shows an assembly diagram of the satellite frame paint spraying and turning device according to the embodiment of the present invention in the vertical parking state of the product, and Figure 1(b) shows the satellite frame paint spraying turning device of the embodiment of the present invention in the product horizontally parked state, That is, the assembly in the flipped state is mainly composed of the connecting frame 1, the tripod bracket 2, the rotating mechanism 3, the supporting system 4, the connecting rod 5, the upper frame connecting ring 6, and the lower frame connecting ring 7.

[0056] figure 2 As shown, the connecting frame 1 is mainly composed of upper and lower frame connecting rods 8, first hexagon head bolts 9, upper frame connectors 10, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com