Optical fiber mix-melting integrated tray capable of being intelligently upgraded

An optical fiber and tray technology, which is applied in the field of optical fiber fusion and integrated trays, can solve the problems of unable to provide circuit board installation space and fixed space, the tray is not suitable for intelligent transformation, and the tray terminal cannot be welded into cables, etc., so as to facilitate intelligent upgrading Effects of retrofitting, convenient retrofitting, and cost reduction of retrofitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

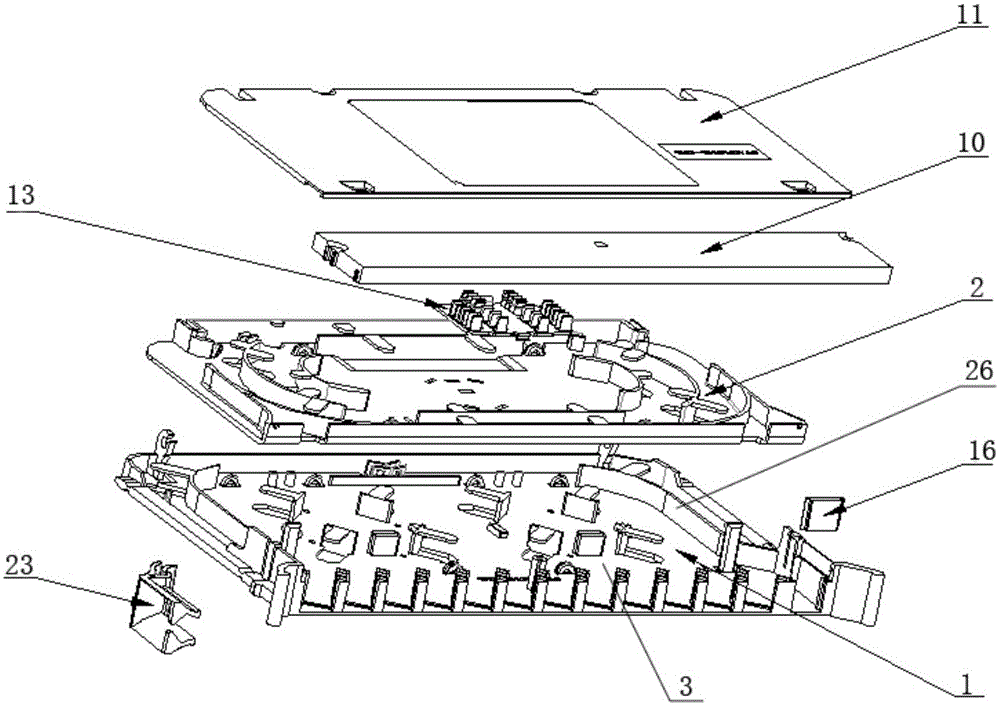

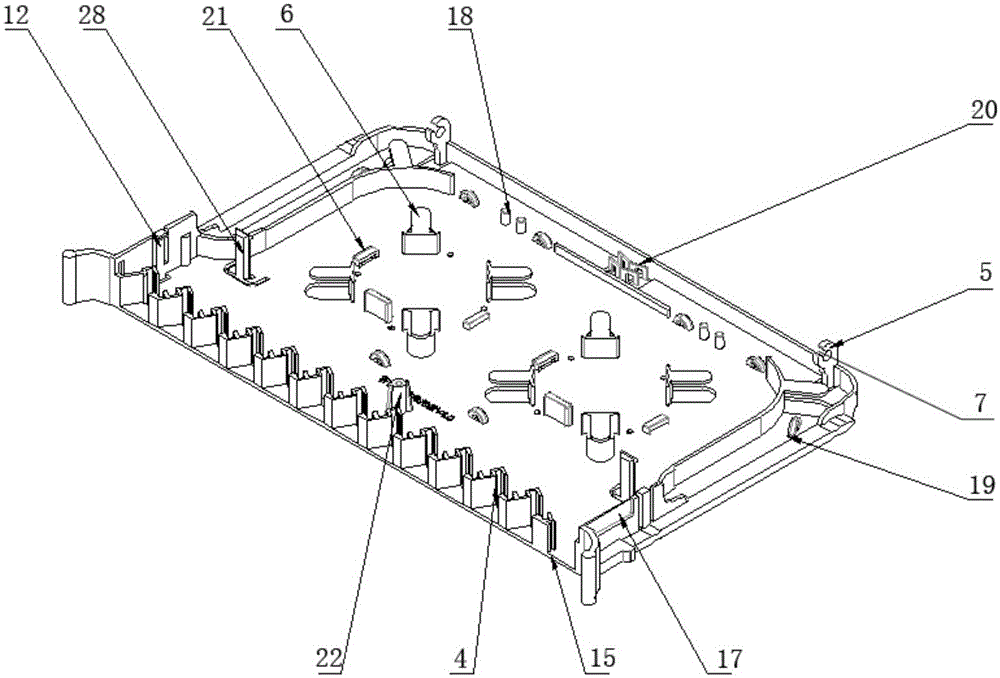

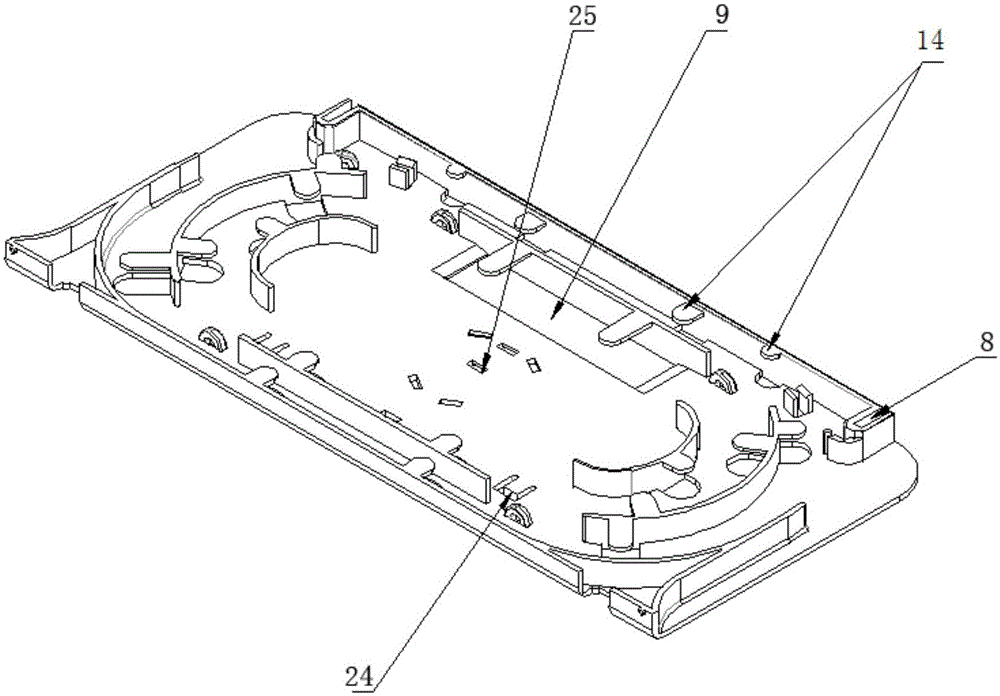

[0025] An intelligent upgradeable optical fiber fusion integrated tray, see Figure 1 ~ Figure 4 : It includes a terminal plate 1, a fusion splice plate 2, and a cover plate. The terminal plate 1 includes a fusion plate support area 3, an adapter installation port 4, a rotating shaft support 5, and a fiber column 6. The left and right sides of the fusion plate support area 3 are respectively An upwardly convex support side wall 26 is arranged, and the fiber winding columns 6 include at least two groups, and the two groups of fiber winding columns 6 are respectively arranged in the area of the support area 3 of the fusion splice tray, and the rotating shaft support 5 includes two, which are respectively located on the terminal disk The two sides of the rear end of 1 are convex upward, the inner side of the rotating shaft support 5 is provided with a notch structure 7 at the oblique upward position, and the two sides of the rear end of the welding plate 2 are provided with a we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com