A method for determining the degree of gas channeling during nitrogen foam flooding

A nitrogen foam, oil displacement process technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve problems such as the timing and intensity of gas channeling that are not quantified

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical scheme of the present invention is as follows:

[0015] A method for determining the degree of gas channeling during nitrogen foam flooding, including the following steps:

[0016] (1) Inject nitrogen foam fluid into the injection well and measure the gas production V of the production well at different times g And liquid production volume V l ;

[0017] (2) Calculate the gas production rate f of producing wells at different times according to formula (I) g ,

[0018]

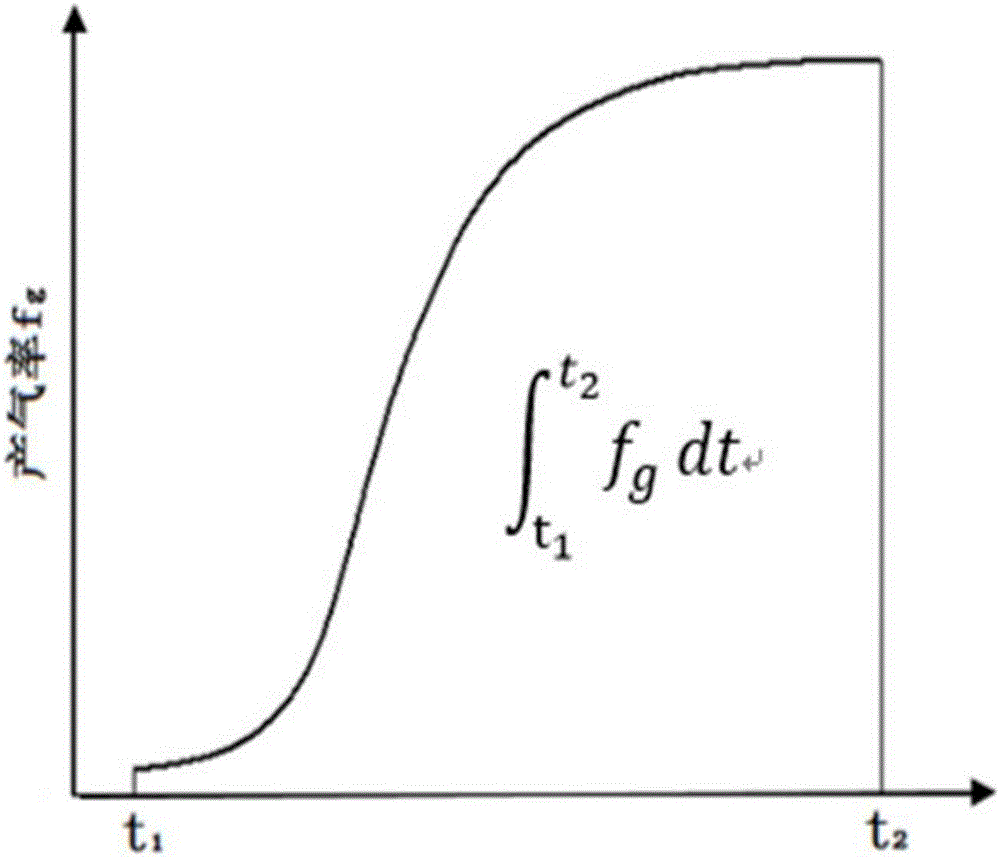

[0019] (3) f calculated at different times g , Draw a curve, calculate the gas production rate rise index I of the production well according to formula (II) g ,

[0020]

[0021] In formula (II), t 1 , T 2 Respectively indicate the start and end time of production; V g1 , V g2 Respectively indicate the gas production at the beginning and end of production; V l1 , V l2 Indicate the liquid production volume at the beginning and end of production respectively;

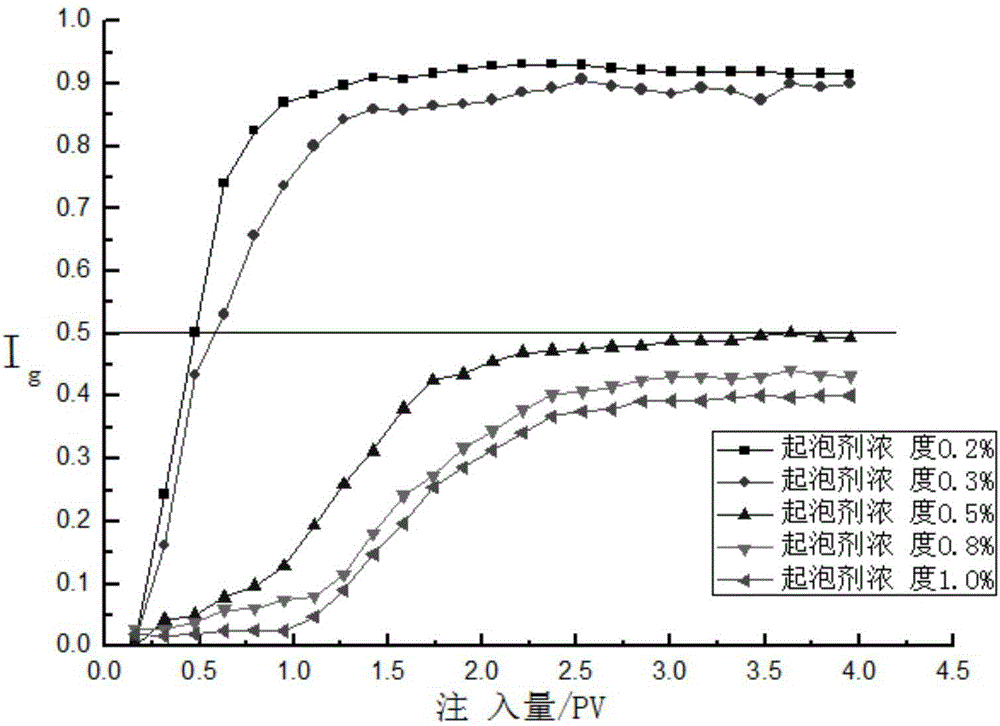

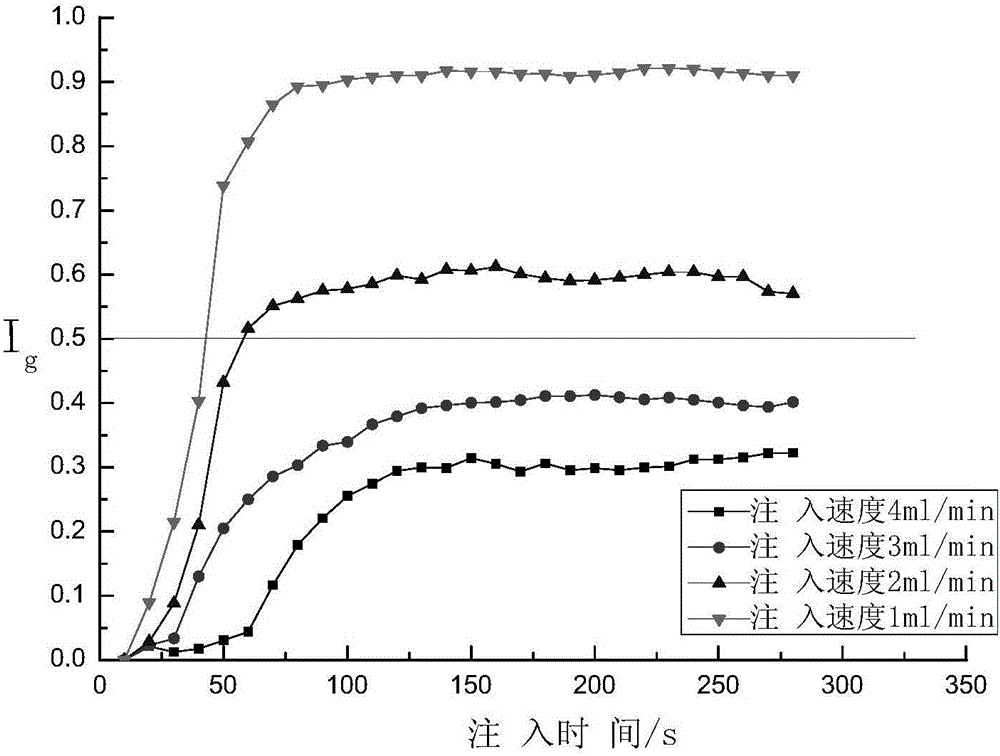

[0022] (4) Determine the degree of gas cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com