Stirring apparatus

A stirring device and stirring blade technology, which is applied in the fields of biochemical cleaning devices, enzymology/microbiology devices, and biochemical instruments, etc., can solve the problem of high power consumption, quasi-speed energy consumption, insufficient fusion of fermentation liquid with oxygen, and increased material costs, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The structure and application process of the present invention will be further described below in conjunction with the accompanying drawings and some embodiments of the present invention.

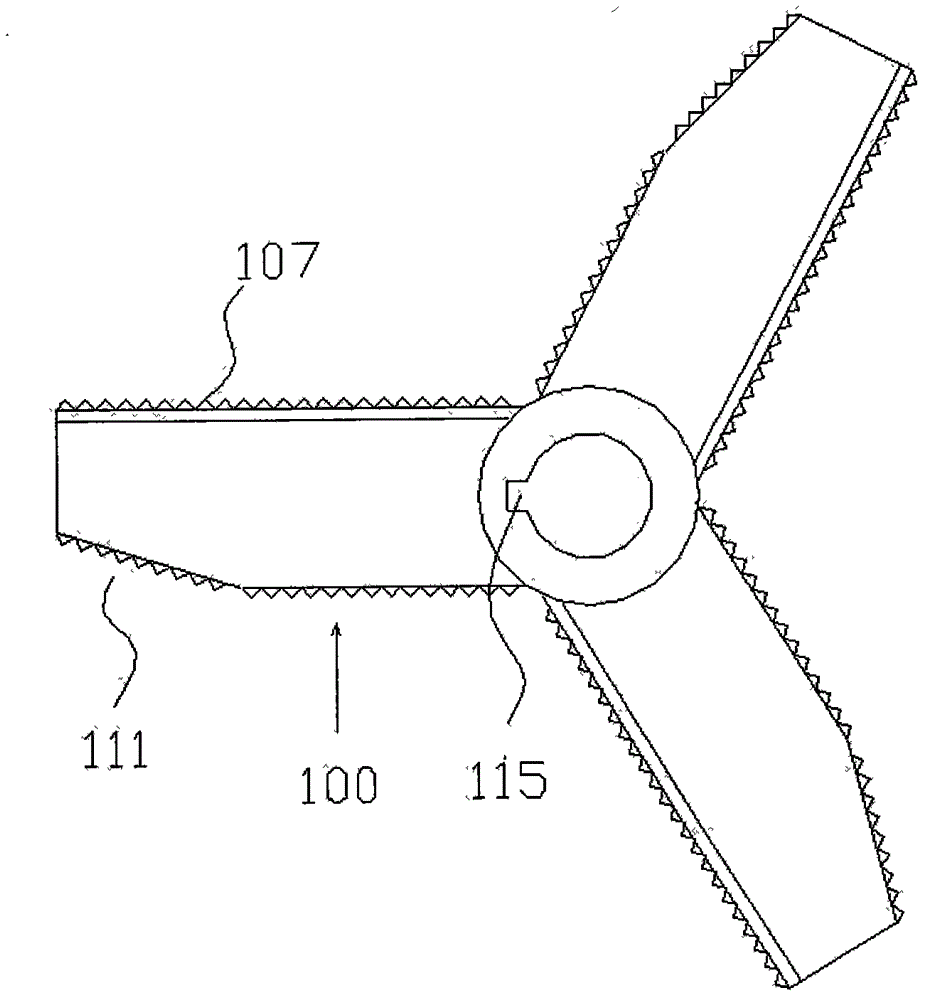

[0012] Such as figure 1 As shown, a stirring device according to an embodiment of the present invention includes three sets of stirring units 100 . The stirring unit 100 includes a housing 101 and a stirring blade 103 .

[0013] Flanges 105 are arranged on the outer sides of the two sides of the clamp shell 101 . The upper and lower ends of the flange 105 are respectively provided with screw holes 113 . In actual use, three sets of stirring units 100 can be arranged around the rotating shaft, and the three sets of stirring units 100 can be connected by screws so that the three sets of stirring units can be sleeved on the rotating shaft. The motor rotates the rotating shaft and simultaneously drives the stirring device to rotate.

[0014] A keyway 115 is provided on the inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com