Segmental assembly bridge erecting machine for construction of small curved bridge

A small curve, bridge erecting machine technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of inconvenient construction, assembly construction is not suitable for large machinery, etc., to achieve convenient adjustment, high degree of automation, and improve construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

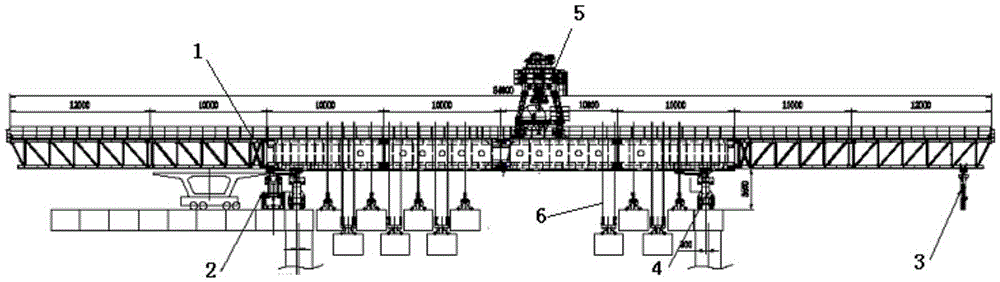

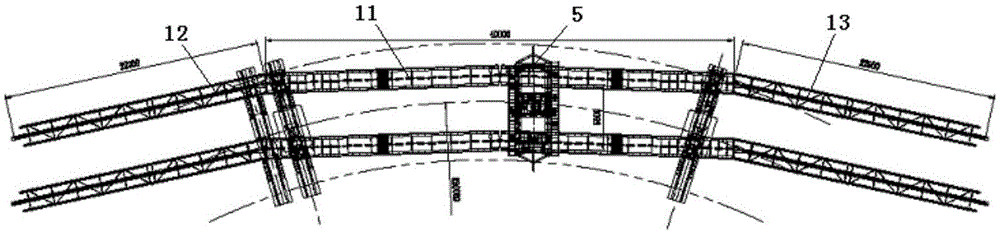

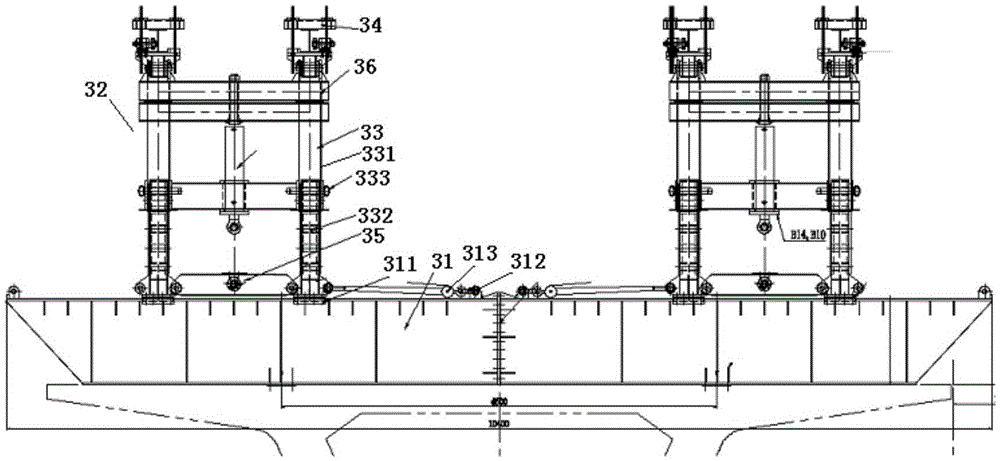

[0042] see figure 1 and 2 , has shown the segmental assembly bridge erecting machine of the construction small curved bridge of the present invention.

[0043] The segmental assembly bridge erecting machine for the construction of small curved bridges at least includes a main girder 1 that can be automatically bent, a rear leg 2, a front leg 3, at least one middle leg 4, and a crane 5 that can walk a folding line And hanger 6, also can comprise electrical system and hydraulic system etc., to provide electrical supply and hydraulic pressure supply.

[0044] Wherein, the main girder 1 that can be bent automatically includes two parallel steel girders, there is no cross connection between the two steel girders, and each steel girder includes a steel box girder 11 in the middle and steel box girders on both sides of the steel box girder 11. The front guide beam 12 and the rear guide beam 13 are composed, wherein, the front and rear guide beams are symmetrically arranged to meet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com