A four-way reversing valve magnetic separation ring press-fitting equipment and press-fitting process

A technology of four-way reversing valve and magnetic separation ring, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of high labor intensity and low production efficiency, and achieve the goal of reducing labor intensity, improving work efficiency, and improving product quality. The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

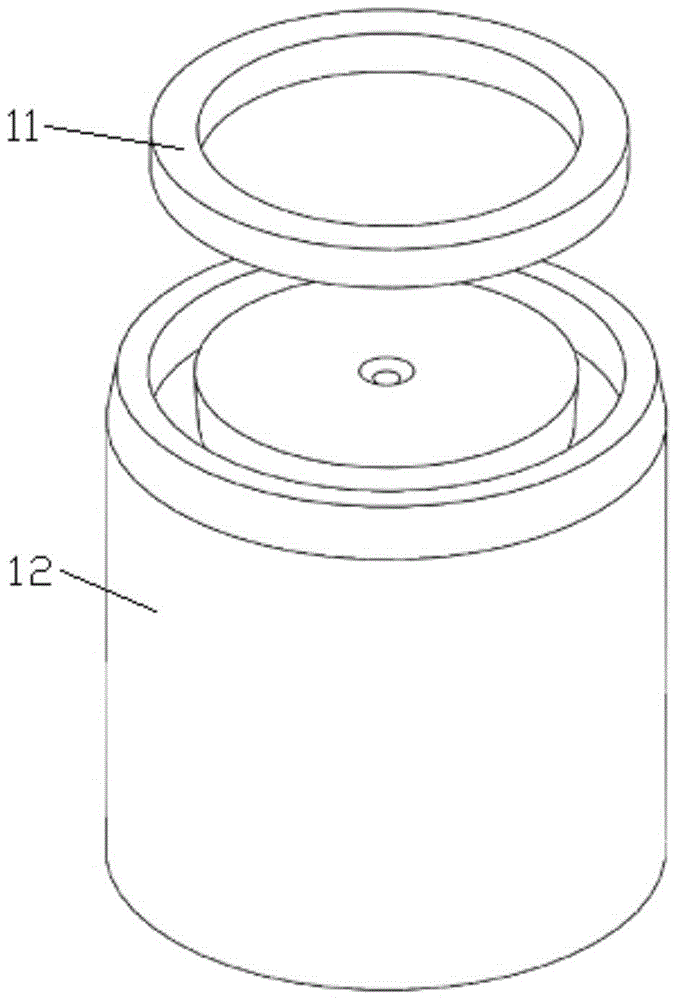

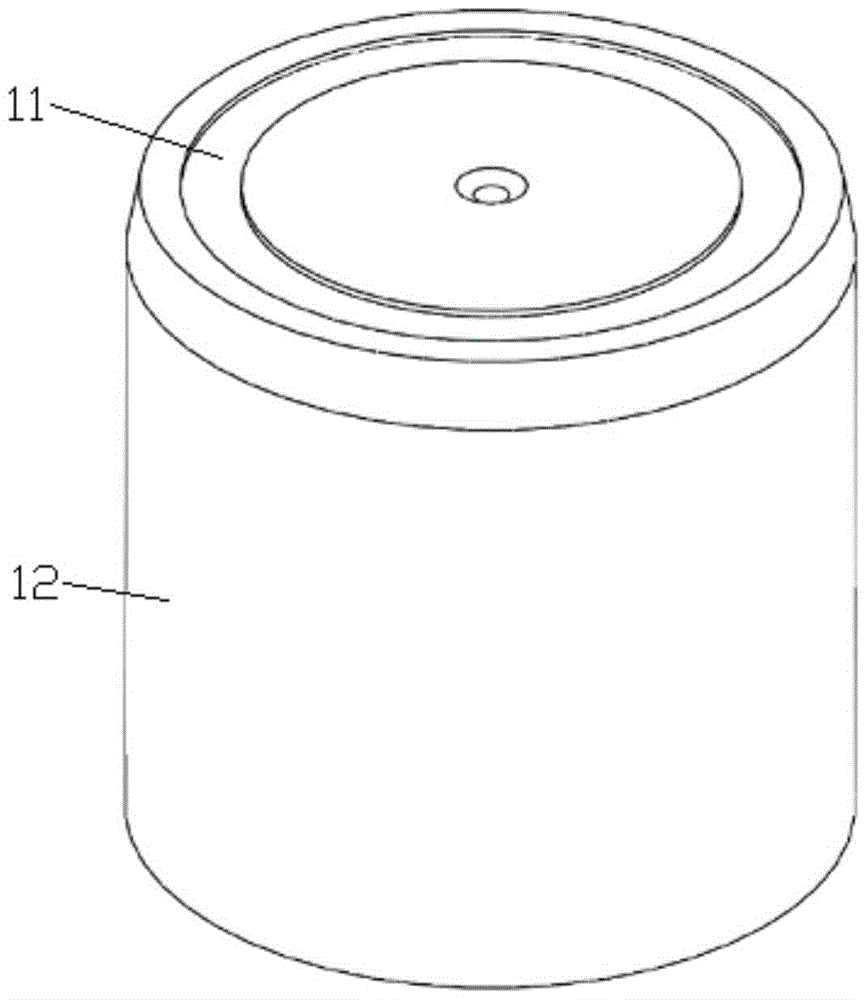

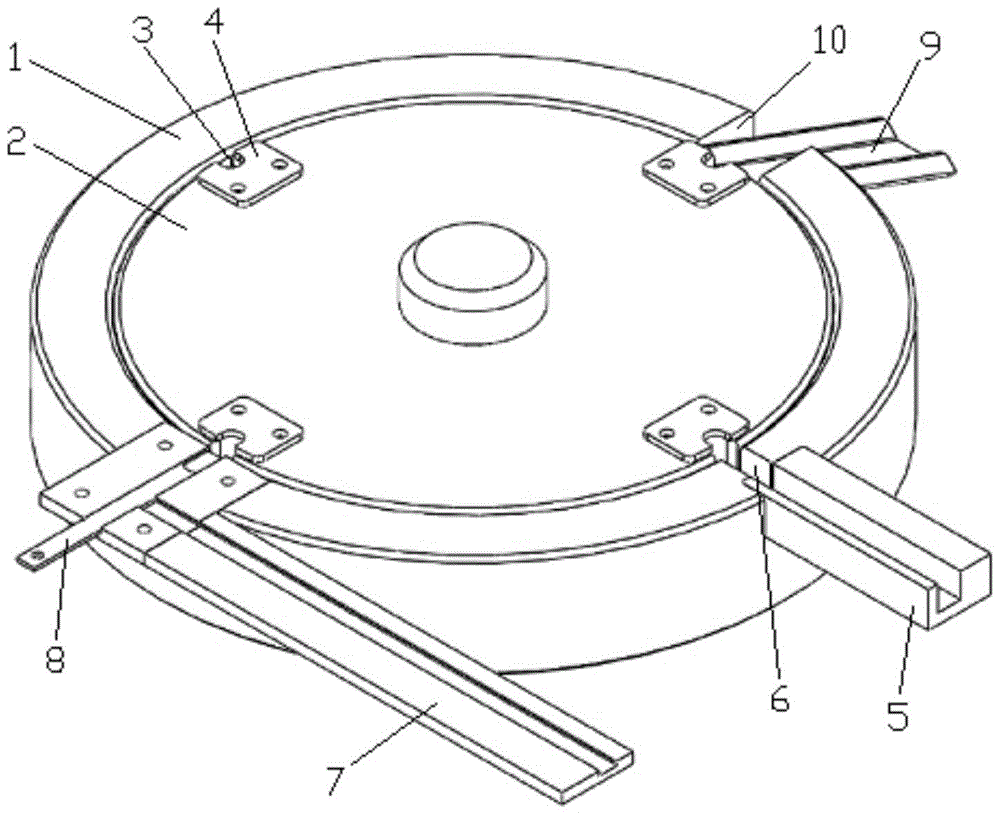

[0030] as attached Figures 3 to 4 The four-way reversing valve sub-magnetic ring press-fitting equipment shown includes a disc base 1, and the disc base 1 is provided with a circular pit, and an indexing plate is rotatably installed in the pit. 2, and the outer peripheral surface of the indexing plate 2 is closely matched with the inner surface of the pit to avoid displacement of the workpiece. The outer peripheral edge of the indexing plate 2 is provided with a plurality of grooves 3 for placing workpieces; the upper end surface of the indexing plate 2, above the grooves 3, is provided with a retaining ring piece 4 to limit the movement of the magnetic ring. The inner edge of the disc base 1 is provided with a head feeding station, a sub-magnetic ring feeding station, a pre-pressing station, a riveting station and a discharging station corresponding to the groove 3 .

[0031] The head feeding station includes a head feeding track 5 located outside the disc base 1 and a head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com