Wiper blade

A technology of wiper blade and wiper arm, which is applied in the direction of vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve the problem of cleaning process consumption and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

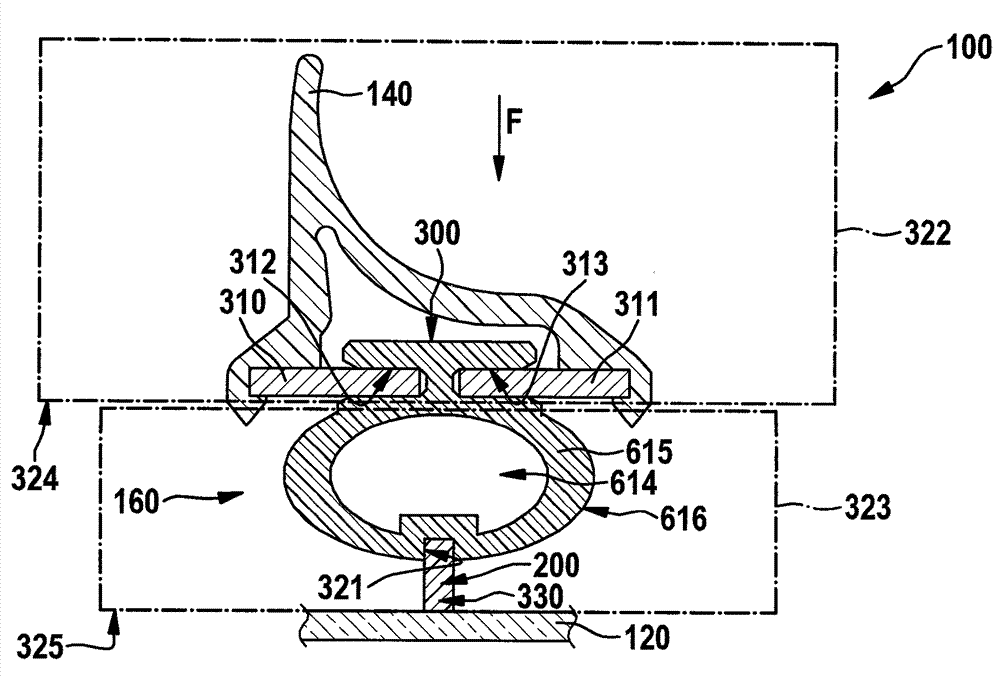

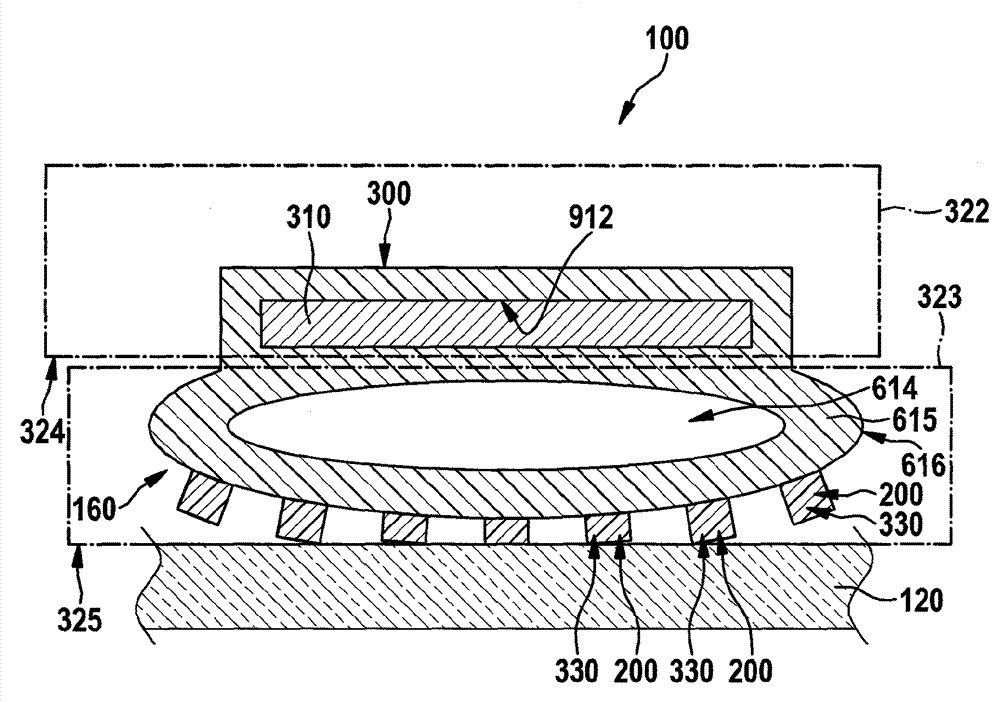

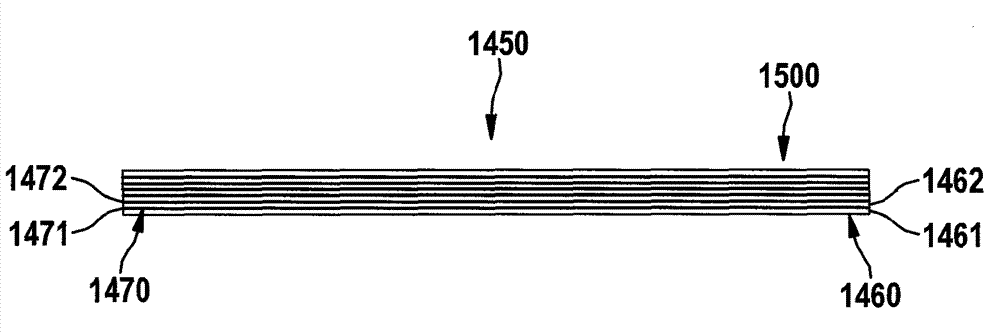

[0056] According to one embodiment, the wiper and cleaning element 160 has a wiper lip 320 on which the fiber system 200 or at least one fiber unit 330 of the fiber system is arranged. In this case, in order to receive the at least one fiber unit 330 at least in sections, the wiper lip 320 preferably has at least one receptacle 321 that is formed in a groove-like manner in sections. Preferably, the wiper lip 320 or the wiper and cleaning element 160 is formed in one piece with the carrier element 300.

[0057] Figure 4 show figure 1 The wiper blade 100, which has image 3 The carrying section 322 and the wiping and cleaning section 323 and an intermediate section 420. The intermediate section is arranged diagrammatically between the load-bearing section 322 and the wiper and cleaning section 323.

[0058] The middle section 420 preferably has a stabilizing section 410 arranged on the underside 324 of the load-bearing section 322, on which two transverse recesses 412, 413 and a fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com