A Screening Method for Poor Polymer Injection Wells and Polymer Channeling Wells

A technology for channeling polymerization and polymer, which is applied in the field of optimized production allocation and injection in oilfields, and can solve problems such as increasing polymer output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

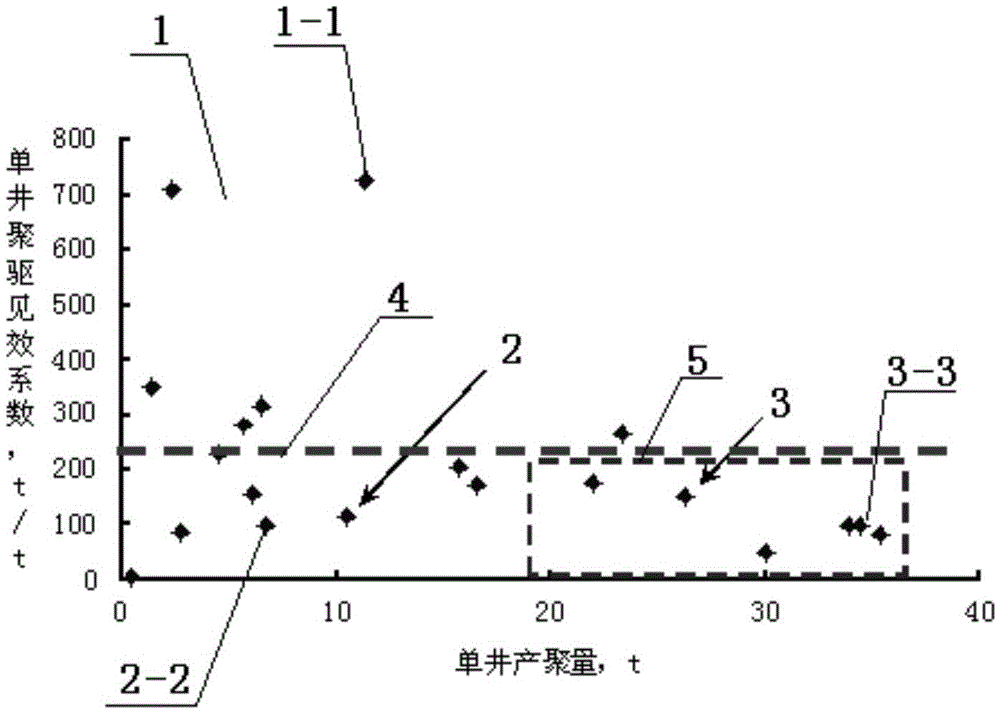

[0023] A screening method for poor polymer injection wells and polymer channeling wells, comprising the following steps:

[0024] (1) Collect the oil production data and polymer production data of each production well in the polymer flooding block, and calculate the cumulative oil increase and cumulative polymer production of each production well at the screening time; the polymer flooding block is Refers to a development unit with an independent injection-production system that implements polymer flooding in an oilfield;

[0025] (2) Calculate the ratio of the accumulative oil increment and the accumulative polymer production of a single well to obtain the polymer injection effectiveness coefficient of a single well; the single well refers to a single production well in the polymer flooding block;

[0026] (3) Establish a coordinate system: take the effective coefficient of polymer injection in a single well as the ordinate, and the cumulative polymer production in a single w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com