A kind of preparation technology and application of rice-drinking distiller's mother fortified with good yeast

A technology of rice-rinsing distiller's yeast, which is applied in the preparation of alcoholic beverages, biochemical equipment and methods, and methods based on microorganisms. It can solve the problems of increasing the production process of purebred koji, complicated processes, and aging of rice-rinsing distiller's yeast. Achieve excellent fermentation performance, improve fermentation performance, and solve aging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

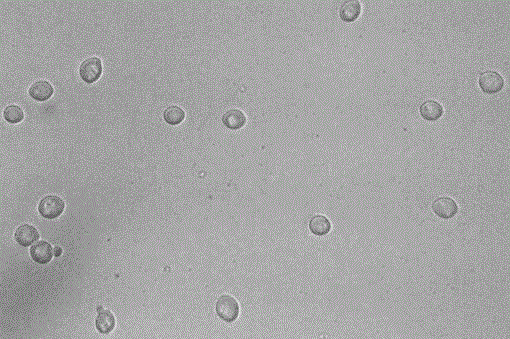

Image

Examples

Embodiment 1

[0026] A kind of preparation process of rice-drinking distiller's mother for strengthening excellent yeast of the present invention comprises the following steps:

[0027] ⑴ Soaking rice: The soaked rice should be rinsed with clean water and drained.

[0028] ⑵ Steamed rice: The steamed rice is required to be cooked but not mushy, the rice grains are soft, and there is no white heart inside.

[0029] (3) Sprinkle with water: first pour with cold water, then with warm water at 38°C until the product temperature is 27°C.

[0030] ⑷ Putting in the vat and building the nest: including mixing glutinous rice, Xiaoqu and active dry yeast thoroughly to form an inverted horn-shaped concave round nest. The formula is 125 kg of glutinous rice plus 220 grams of Xiaoqu and 1 gram of active dry yeast per cylinder. The product temperature after the nest is controlled at 25°C.

[0031] ⑸ Saccharification and adding koji and water: When the rum is saccharified to 4 / 10 of the rice nest height...

Embodiment 2

[0039] A kind of preparation process of rice-drinking distiller's mother for strengthening excellent yeast of the present invention comprises the following steps:

[0040] ⑴ Soaking rice: The soaked rice should be rinsed with clean water and drained.

[0041] ⑵ Steamed rice: The steamed rice is required to be cooked but not mushy, the rice grains are soft, and there is no white heart inside.

[0042] (3) Sprinkle with water: first pour with cold water, then with warm water at 42°C until the product temperature is 30°C.

[0043] ⑷ Putting in the vat and building the nest: including mixing glutinous rice, Xiaoqu, and active dry yeast to form an inverted trumpet-shaped concave round nest. The product temperature after the nest was controlled at 28°C.

[0044] ⑸ Saccharification and adding koji and water: When the rum is saccharified to 7 / 10 of the height of the rice nest, add wheat koji and water. The formula is to add 29.5 kg of wheat koji and 150 kg of water for every 125 kg ...

Embodiment 3

[0052] A kind of preparation process of rice-drinking distiller's mother for strengthening excellent yeast of the present invention comprises the following steps:

[0053] ⑴ Soaking rice: The soaked rice should be rinsed with clean water and drained.

[0054] ⑵ Steamed rice: The steamed rice is required to be cooked but not mushy, the rice grains are soft, and there is no white heart inside.

[0055] ⑶ Sprinkle with water: first pour with cold water, then with warm water at 40°C until the product temperature is 28°C.

[0056] ⑷ Putting in the vat and building the nest: including mixing glutinous rice, Xiaoqu, and active dry yeast thoroughly to form an inverted trumpet-shaped concave round nest. The product temperature after the nest was controlled at 26°C.

[0057] ⑸ Saccharification and adding koji and water: When the rum is saccharified to 6 / 10 of the height of the rice nest, add wheat koji and water. The formula is to add 29.5 kg of wheat koji and 148 kg of water for ever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com