An oil scraping device for a sucker rod

An oil scraping device and oil scraper technology, which is applied to cleaning appliances, wellbore/well components, earth-moving drilling, etc. The oil scraping device cannot work normally, the airbag wall is worn and thinned, etc., to avoid the failure of normal work, easy installation and manufacturing, and reduce labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

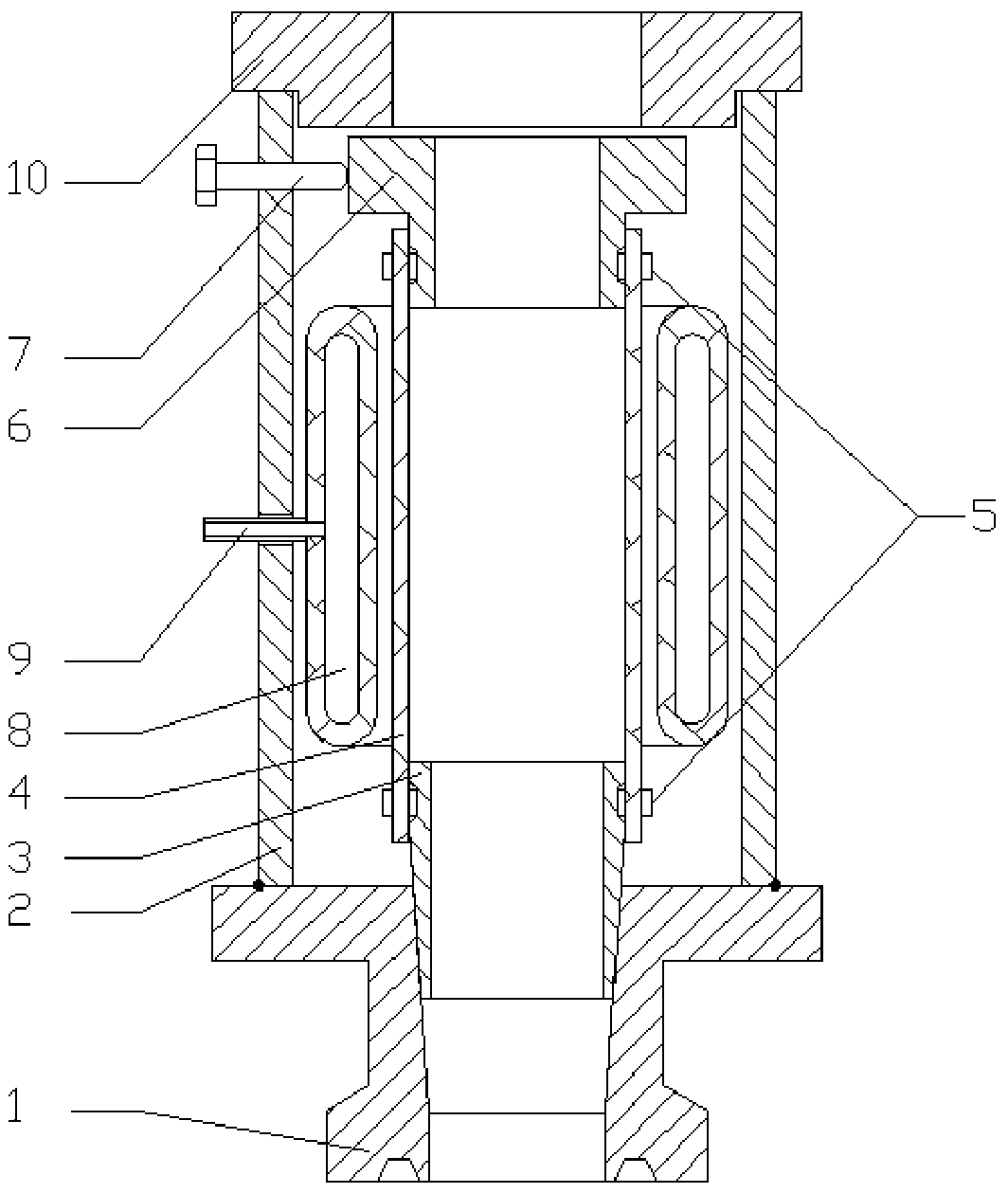

[0023] Attached below figure 1 Specific embodiments of the invention will be described in detail.

[0024] The sucker rod oil scraping device of the present invention, such as figure 1 As shown, it includes a base 1 , an outer cylinder 2 , a cylindrical airbag 8 , an airbag inflation nozzle 9 , an operating table 10 and a positioning device, and the positioning device includes a connector 3 , an elastic non-metallic oil wiper 4 and a centralizer 6 . The console 10 is a stepped cylinder with a through hole, and is placed on the upper end surface of the outer cylinder 2 . The outer diameter of the cylinder at the bottom of the console 10 is smaller than the inner diameter of the outer cylinder 2 , and the outer diameter of the cylinder at the top of the console 10 is larger than the outer diameter of the outer cylinder 2 . The upper end surface of the base 1 and the lower end surface of the outer cylinder 2 are welded together concentrically. The outer cylinder is a tubular b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com