Blade drawing tongs

A kind of technology of drawing pliers and pliers, which is applied in the field of equipment for taking out blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

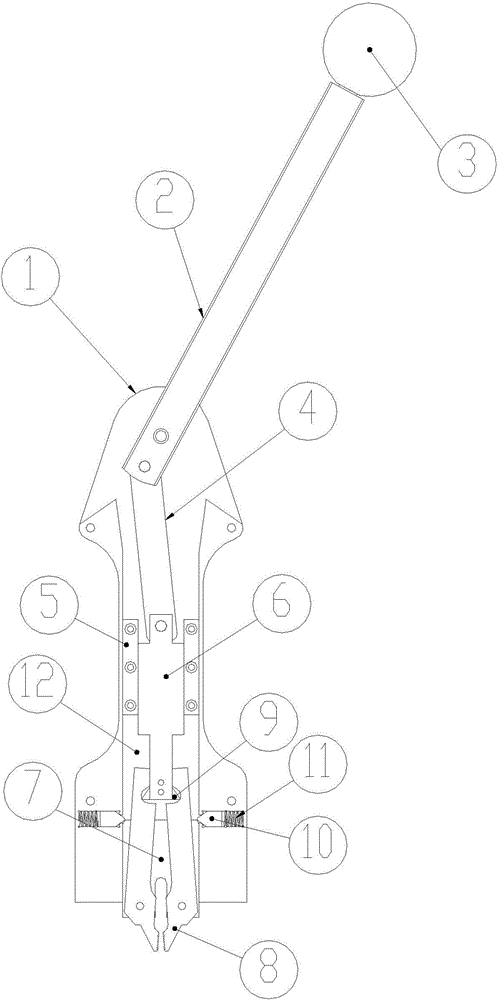

[0017] Such as figure 1 As shown, the knife-drawing pliers described in this embodiment includes a pliers body 1. The pliers body 1 can be combined with two panels with grooves in the middle. A vertical inner cavity 12 is formed in the middle of the pliers body 1. The inner cavity The lower end of 12 is provided with a moving block 7 that can be displaced up and down relative to the caliper body, and the moving block 7 is provided with two parts that form the clip 8 through the rotating shaft, and the two parts of the clip 8 rotate along the rotating shaft to realize the clamping and loosening of the clip 8; The inner sides of the upper ends of the two parts of the clip 8 are provided with arc-shaped grooves, and the upper end of the inner cavity 12 is provided with an operating piece that can displace up and down. The lower end of the operating piece is provided with a cam block 9, and the cam block 9 is located inside the arc-shaped groove; An accommodating groove is respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com