A mechanical system of a white moth larva screen spraying robot

An American white moth and mechanical system technology, applied in the field of robotics, can solve problems such as restrictions on popularization and application, complex environments, and changing spraying objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with embodiment, further illustrate the present invention.

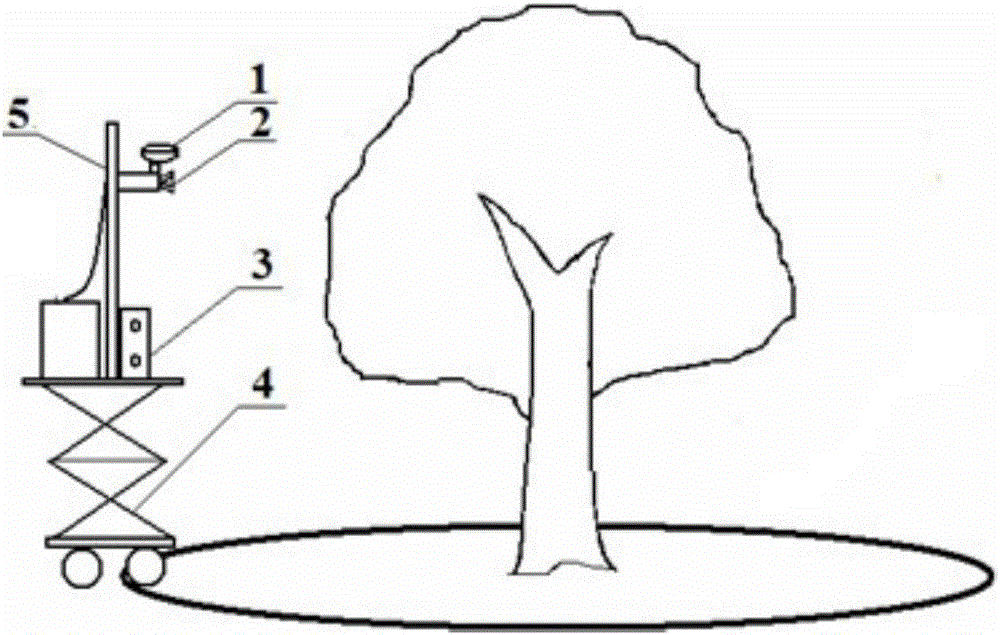

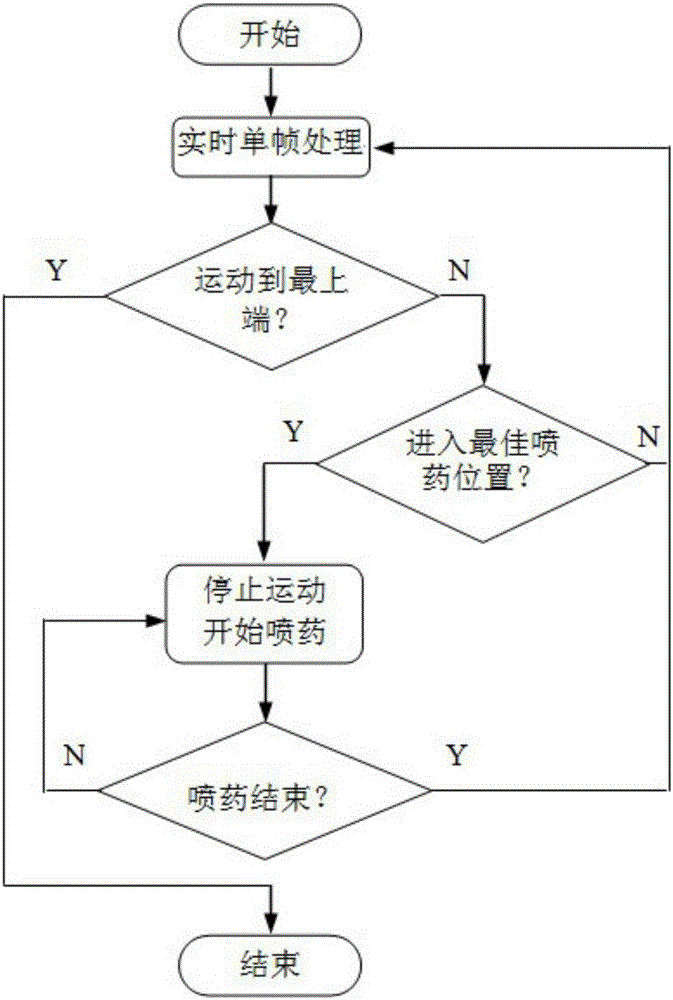

[0041] see Figure 1-Figure 11 , the distribution of the larval screens of the American white moth is extremely complex, which causes great difficulties in processing. In order to improve the efficiency and precision of the system, this research sets some working prerequisites:

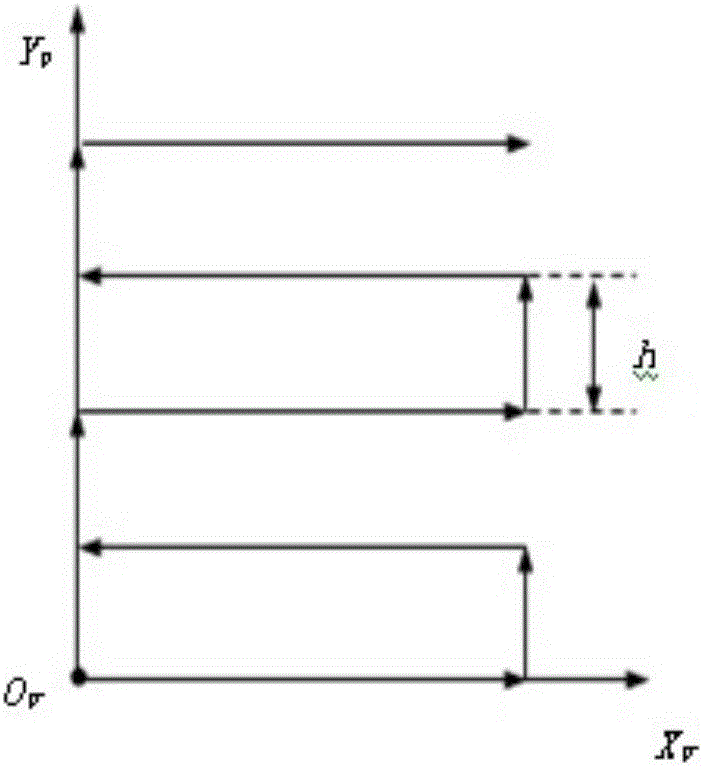

[0042] (1) The main motion of the mechanical system is a two-dimensional motion in the vertical plane. Because the spraying objects are often huge plants, and the spray angle of the nozzle has a three-dimensional coverage area, as long as it can be sprayed within this range, too fine three-dimensional space movement will cause movement redundancy and low processing efficiency. Therefore, this study The two-dimensional motion mode is adopted, and in order to obtain a better video anti-shake effect, the movement of the camera should be kept at a uniform horizontal or vertical speed as much as possible.

[0043] (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com