A control system of a mixing plant

A technology of control system and mixing station, which is applied to control devices, batching and batching instruments, etc., can solve the problems of uncontrollable state, no joint protection protection system, hidden safety hazards, etc., and achieve the effect of avoiding operation errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings and embodiments. The described embodiments are only part of the embodiments of the present invention, but are not used as a basis for limiting the present invention. All other embodiments obtained by those skilled in the art without creative efforts shall fall within the scope of protection of the present invention.

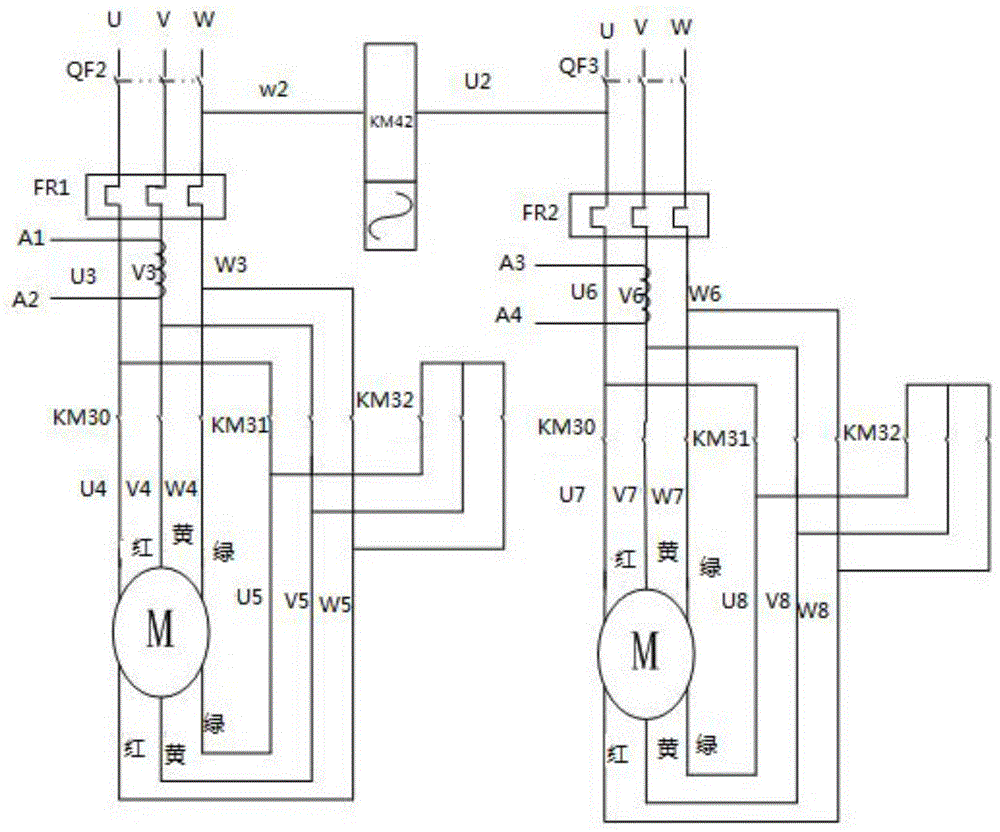

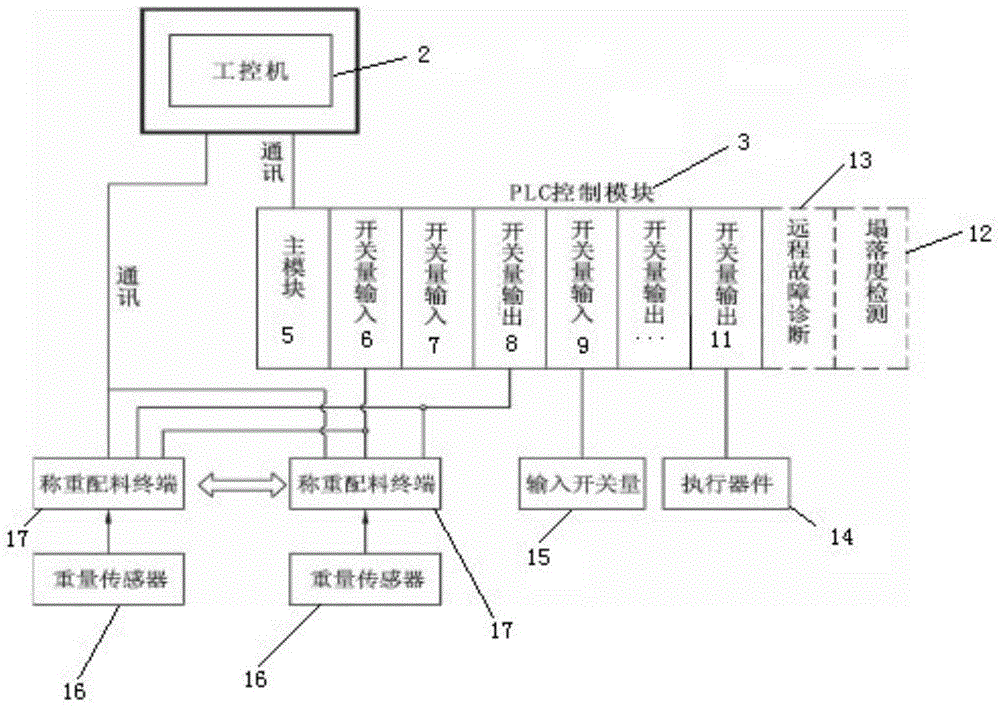

[0020] figure 1 The control block diagram of the electrical control system of the mixing station of the present invention is provided in . , the basic principle is to use the industrial computer 1 to control the control module 2, and to control each terminal instrument 3, so as to realize the independent control of multiple terminal instruments 3, where the terminal instrument 3 can be a sand feeder, stone Feeding machine, water adding machine, etc., also including dust remover, etc., the terminal instrument 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com