Cylinder locking method

A cylinder and locking column technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of limited space, labor, inconvenient operation, etc., and achieve simple structure, low labor intensity, and convenient locking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

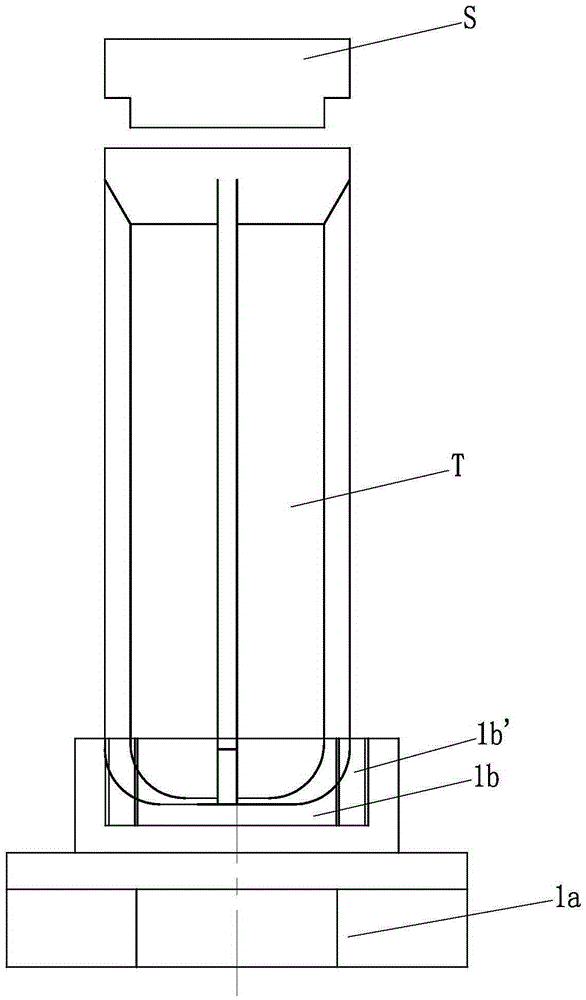

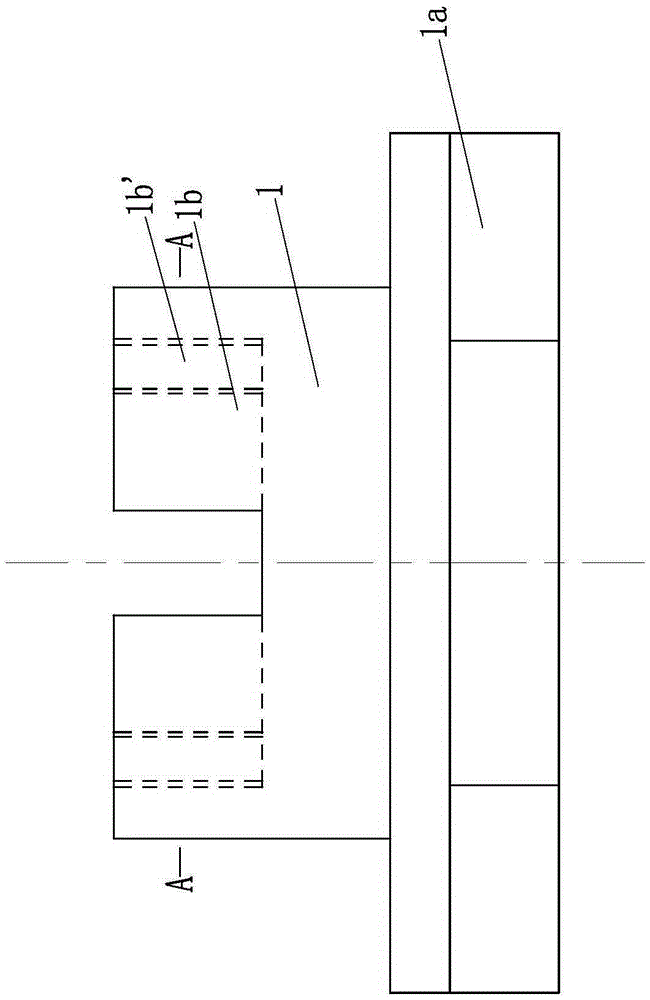

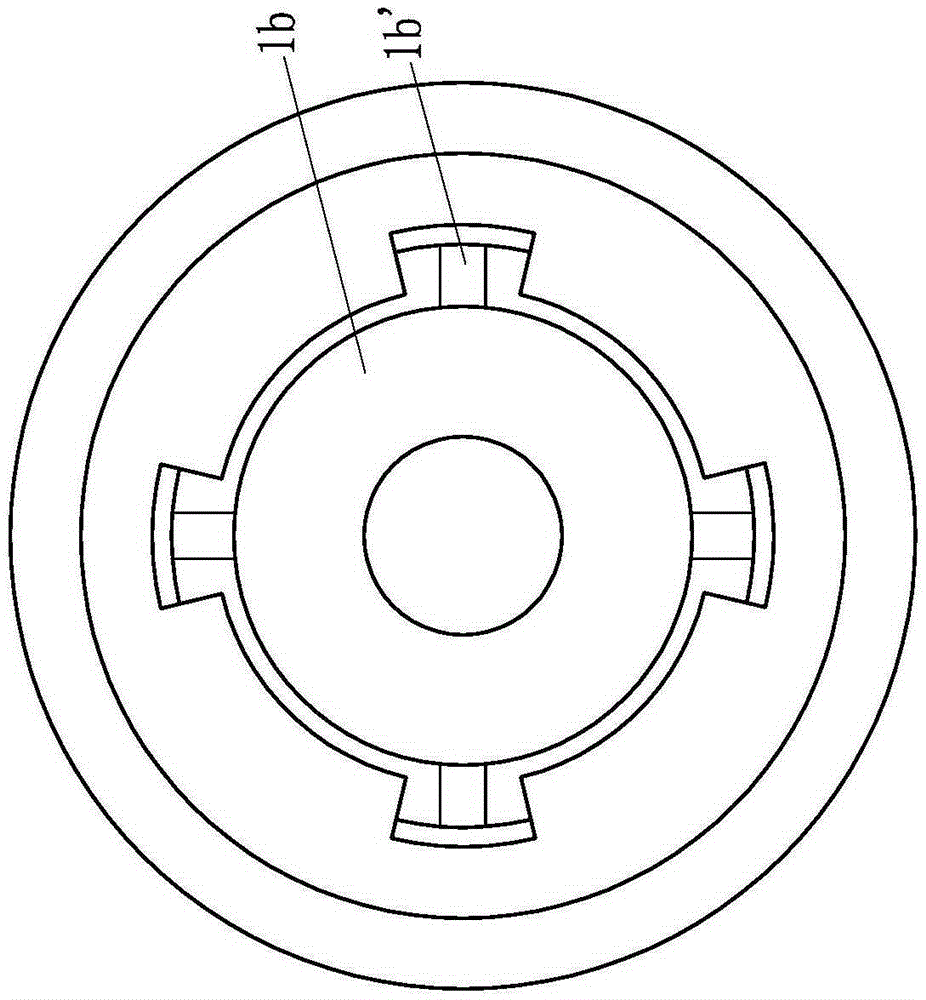

[0018] Such as figure 1 , 2 And shown in 3, a cylinder locking method is characterized in that comprising the following steps:

[0019] Step a: first fix the upper cover S, and initially screw the upper cover S and the filter element cylinder T together;

[0020] Step b: Select a locking column of corresponding size and specification. The body 1 of the locking column is made of iron or stainless steel. The part is a regular hexagonal flat part 1a, and the height of the regular hexagonal flat part is 3-5mm. The number of the limiting pits 1b' is four, and the depth of the limiting pits 1b' is 0.5-1.5mm. The center of the top surface of the large-diameter section of the body 1 is provided with a circular groove 1b, and 2-5 limit pits 1b' are evenly distributed on the groove wall of the circular groove along the circumferential direction. These limit pits 1b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com