A coalbed methane wellbore gas-liquid two-phase flow simulation device for multi-coal seam co-production

A technology of gas-liquid two-phase flow and coalbed methane well, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., and can solve problems such as interlayer interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

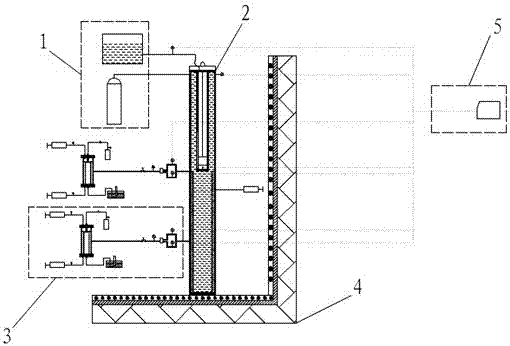

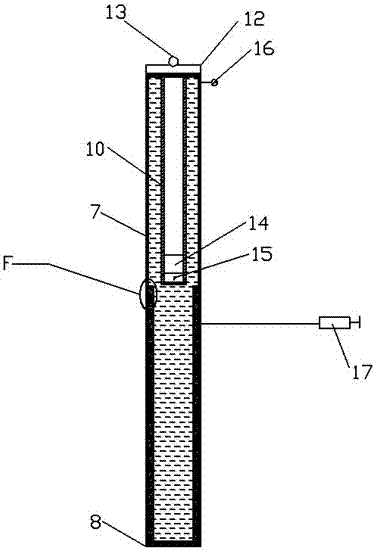

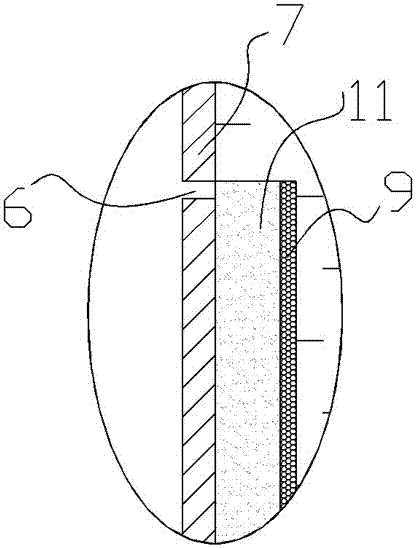

[0023] Embodiment of the present invention: a coalbed methane wellbore gas-liquid two-phase flow simulation device for multi-coal seam co-production, as attached figure 1 As shown, it includes a recovery system 1, the recovery system 1 is connected to the top of the wellbore simulation device 2, the reservoir simulation system 3 is connected to the guide hole 6 in the wellbore simulation device 2, and the adjustment system 4 is connected to the outside and bottom of the wellbore simulation device 2 for Control the inclination of the wellbore simulation device 2, and the data acquisition system 5 is connected to the connection between the recovery system 1, the wellbore simulation device 2 and the reservoir simulation system 3, wherein the wellbore simulation system 2 can provide a gas-liquid two-phase flow we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com