Optical body, optical body manufacturing method, solar shading member, window member, interior member, and fitting

A technology of optical body and optical layer, applied in the field of optical body, can solve problems such as temperature rise and achieve the effect of suppressing the overall reduction

Active Publication Date: 2015-01-21

DEXERIALS CORP

View PDF2 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] In other words, the above-mentioned directional reflector has a problem that as the directional reflection component decreases, a larger amount of sunlight reaches the ground and causes an increase in temperature near the ground surface

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

no. 1 approach

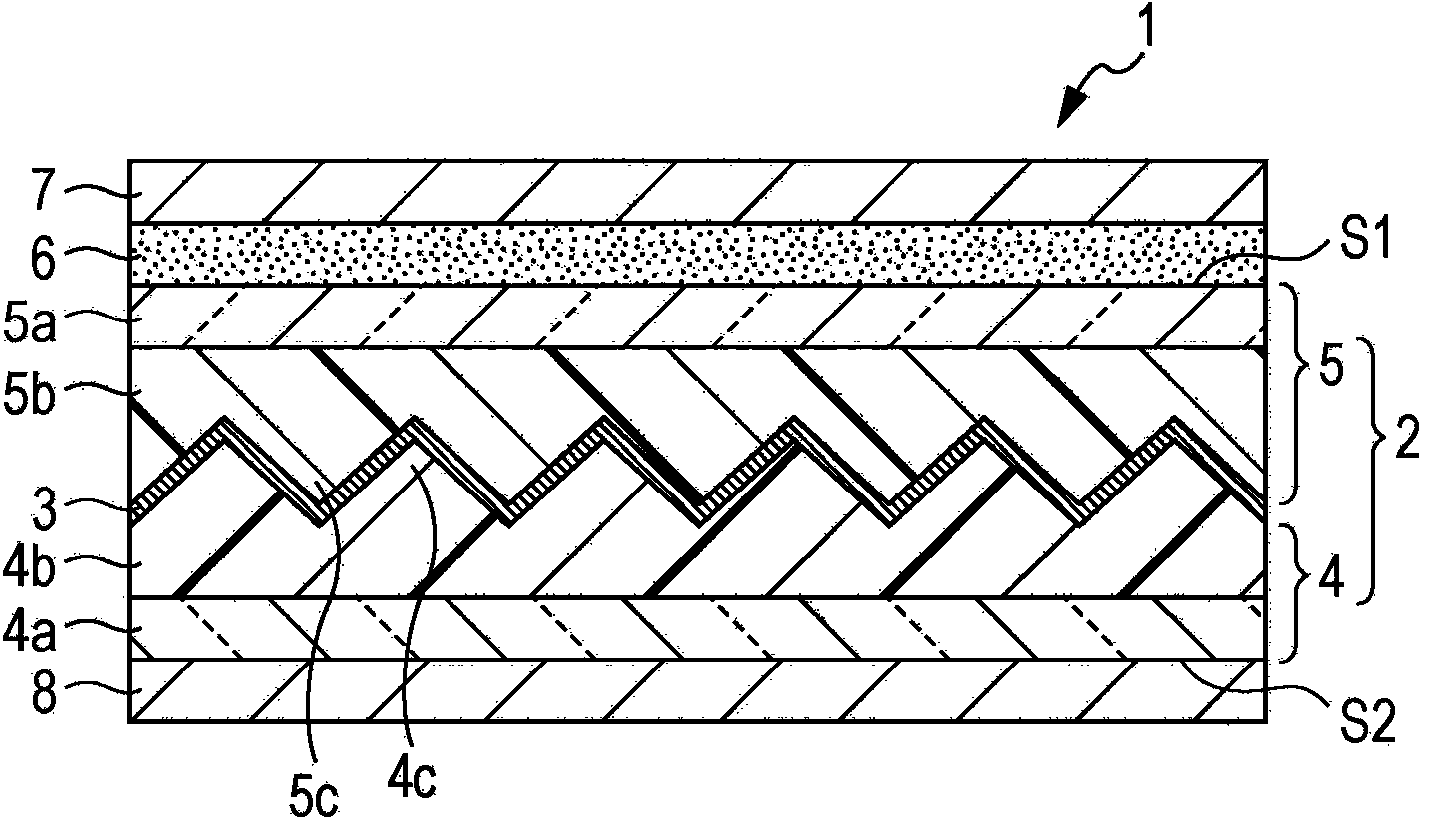

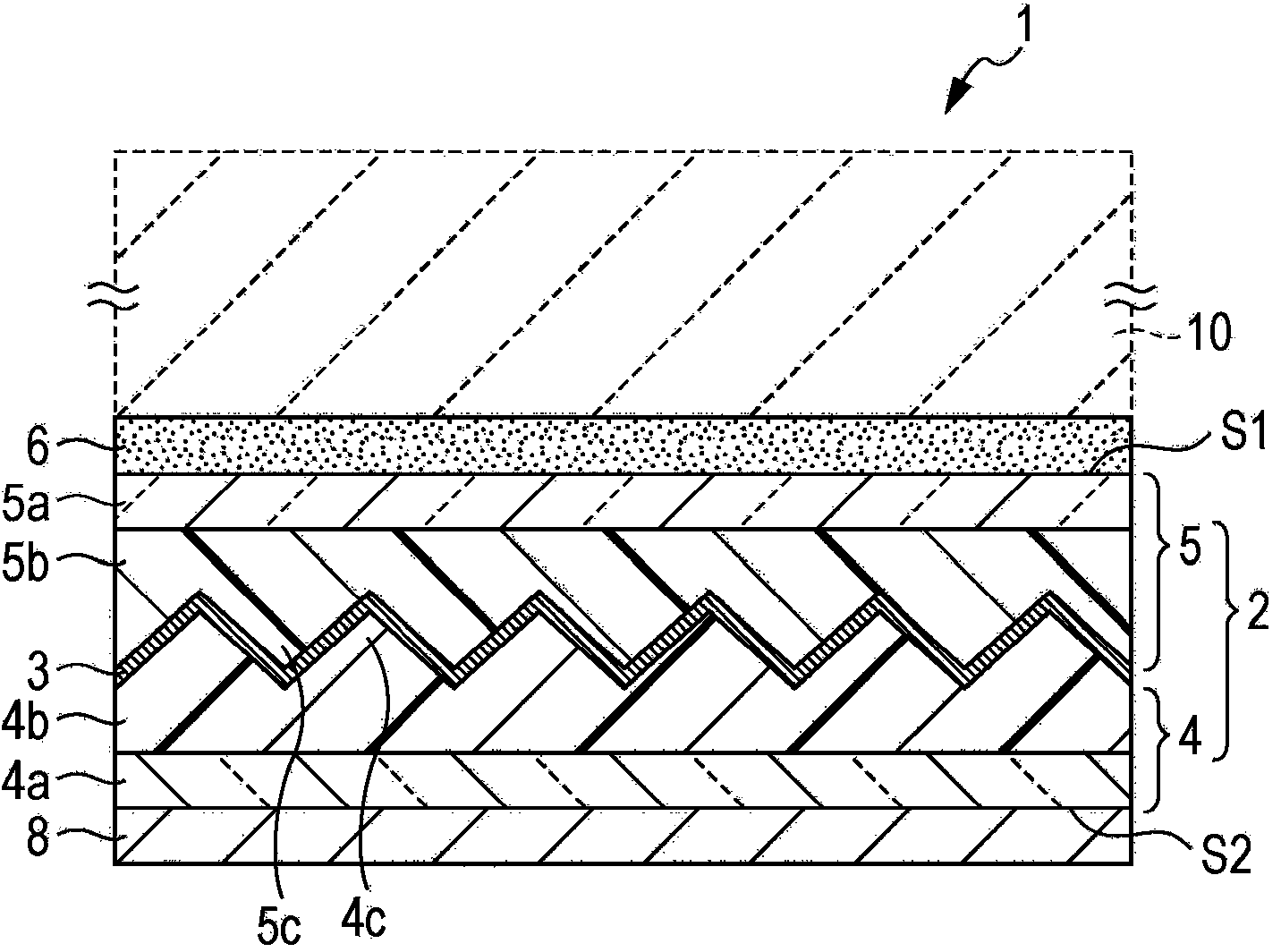

[0054] First Embodiment (Example of Optical Body Forming Reflective Layer in Pyramid Pattern)

no. 2 approach

[0055] Second Embodiment (Example of Sunshade Device Using Optical Body)

no. 3 approach

[0056] Third Embodiment (another example of a solar shading device in which an optical body is applied to a roller shade device)

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Login to View More

Abstract

An optical body includes a first optical layer, a second optical layer having an incident surface on which light is incident, and a reflecting layer sandwiched between the first and second optical layers, wherein the first optical layer includes a plurality of convex or concave structures formed on or in a surface thereof on which the reflecting layer is disposed, ridges of the convex structures or ridges between the concave structures adjacent to each other have tip portions projecting toward the incident surface side, the tip portions are deformed from an ideal shape, the second optical layer is transparent and has a refractive index of 1.1 or more and 1.9 or less, and the optical body selectively directionally reflects part of light entering the incident surface, which part is in a specific wavelength band, in direction other than the specular reflection direction.

Description

technical field [0001] The present invention relates to an optical body, a method of manufacturing the optical body, a solar shielding member, a window member, an interior member, and a building member. In particular, the invention relates to optical bodies for directional reflection of incident light. Background technique [0002] Recently, cases of coating a layer that partially absorbs or reflects sunlight on architectural glass for high-rise buildings and houses, automobile window glass, and the like have increased. Such a trend is one of the energy-saving measures aimed at preventing global warming, and is also intended to reduce the load on the cooling device that increases due to sunlight energy that enters the room through the window and raises the room temperature. [0003] The light energy introduced by the sun is mainly provided by light in the visible range with a wavelength of 380nm to 780nm and light in the near infrared range with a wavelength of 780nm to 210...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G02B5/08B32B3/30B32B37/02E06B9/24

CPCE06B9/386E06B9/24B60J1/2041G02B5/124E06B2009/2417G02B5/208G02B5/0808B32B3/30B32B37/02

Inventor 影山正光吉田宽则谷岛胜行长浜勉榎本正

Owner DEXERIALS CORP

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com