One-by-one bi-directional feeding device for PCBs

A two-way feeding, one-by-one technology, applied in the direction of thin material processing, object separation, pile separation, etc., can solve the problems of single function, high manufacturing cost, failure of PCB board feeding, etc., to avoid mutual friction and feed stability High and reduce the effect of input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

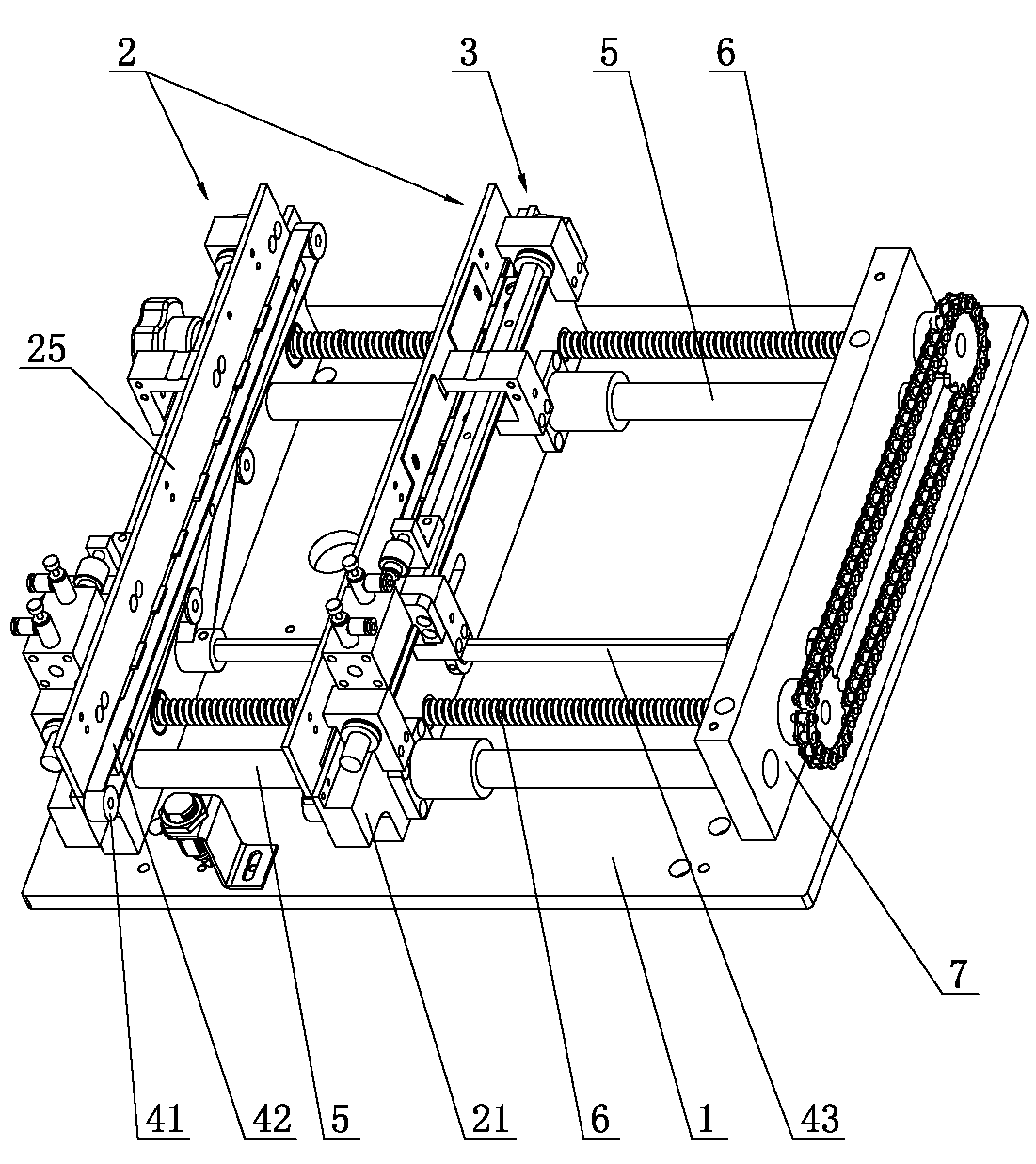

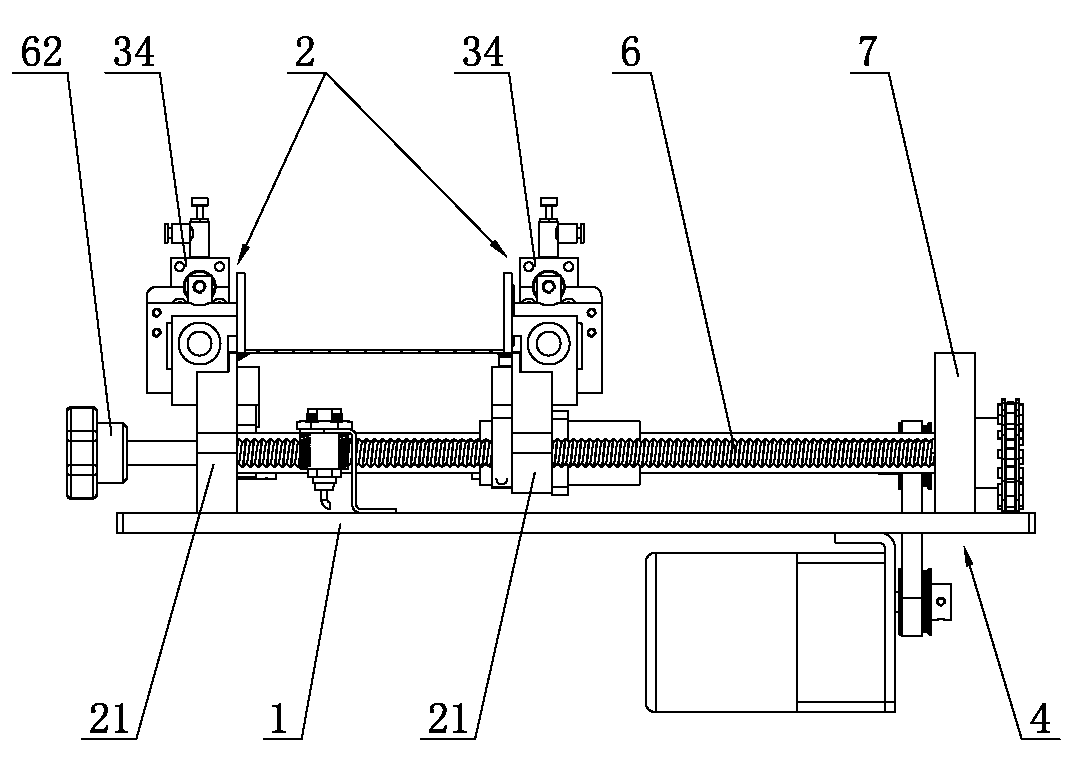

[0024] Such as Figure 1 to Figure 6 As shown, a PCB light board one by one two-way feeding equipment, including a substrate 1 and two sub-board components 2, the two sub-board components 2 are symmetrically installed on the substrate 1, and the sub-board components 2 include The mounting plate 21 of the substrate 1, the inner side of the mounting plate 21 is provided with a plurality of supporting plates 22 at intervals, the upper edge of the mounting plate 21 is equipped with a push plate 24 and a sub-plate for driving the push plate 24 to move back and forth Drive mechanism 3, the push plate 24 is provided with a plurality of protruding teeth 23, each of which protruding teeth 23 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com