A gas chromatography fid automatic ignition detection control method

An automatic ignition, detection and control technology, applied in the field of gas chromatography detection, can solve the problems of ignition failure, error-prone, machine damage, etc., achieve the effect of simple use process and lower skill requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

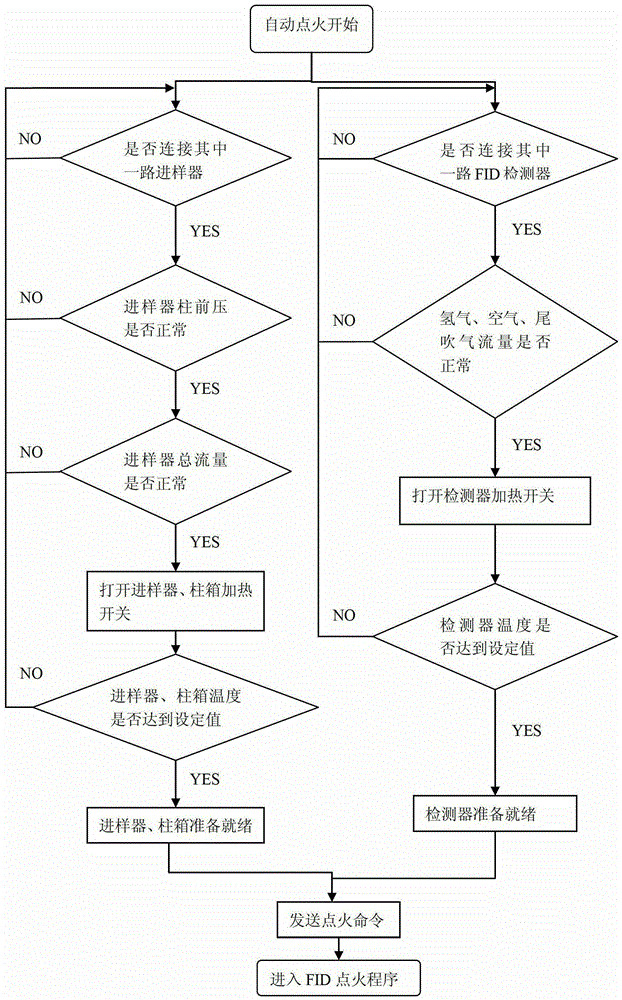

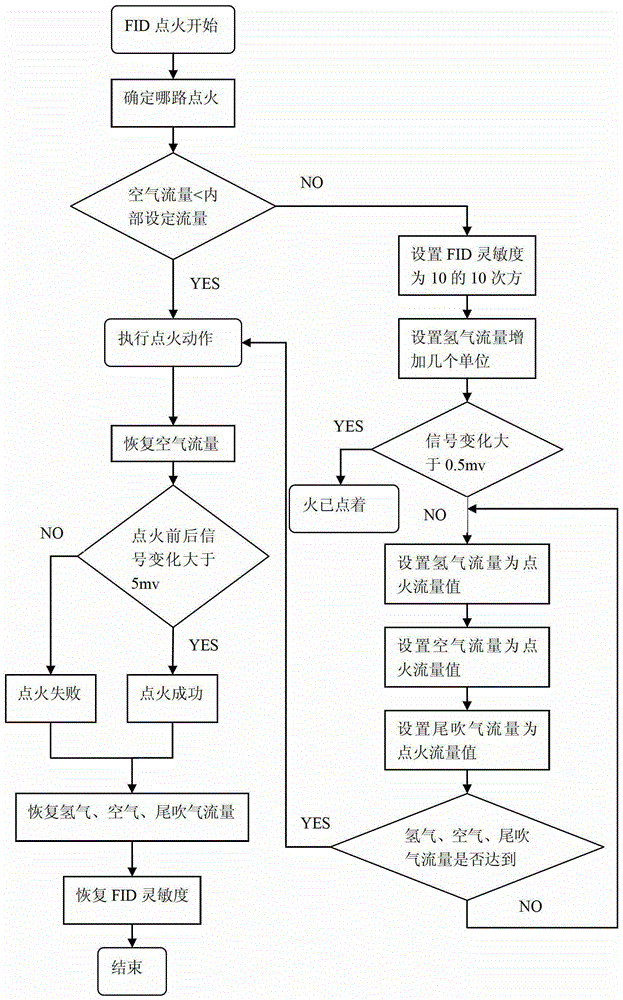

[0018] The prerequisite for the realization of the present invention is that the gas chromatograph must have the electronic flow control technology of the gas circuit system, a temperature control system, an ignition device and a signal detector.

[0019] Before automatic ignition, three major parts of the system must be detected: first, the injector part, including the injector temperature, the carrier gas flow rate in the injector, etc.; second, the column oven part, mainly whether the column oven temperature is normal; , the detector part, including the temperature of the detector, the flow rate of each auxiliary gas of the detector, etc.

[0020] First, confirm whether the user needs automatic ignition. If automatic ignition is required, the system will automatically enter the automatic ignition mode after the self-test is completed. Make sure that there is no air leakage in each gas system. If there is any air leakage, the instrument will automatically alarm during the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com