A high-speed automatic shaping and stacking machine for carpets

A technology of stacking machine and carpet, applied in packaging and other directions, can solve the problems of slow packaging speed and poor consistency of products under manual operation, and achieve the effect of fast packing speed, visual operation and good overall rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

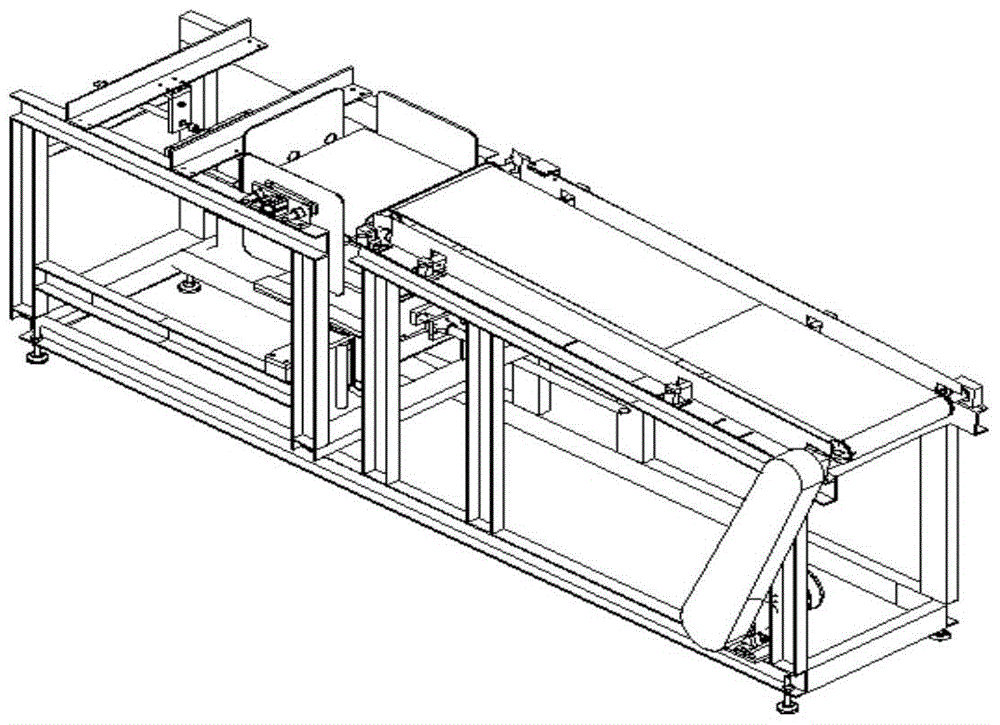

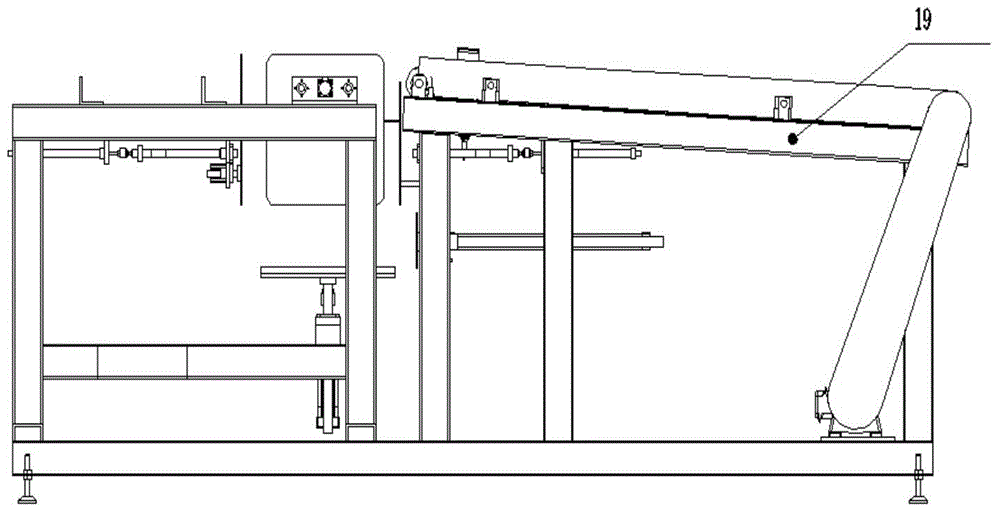

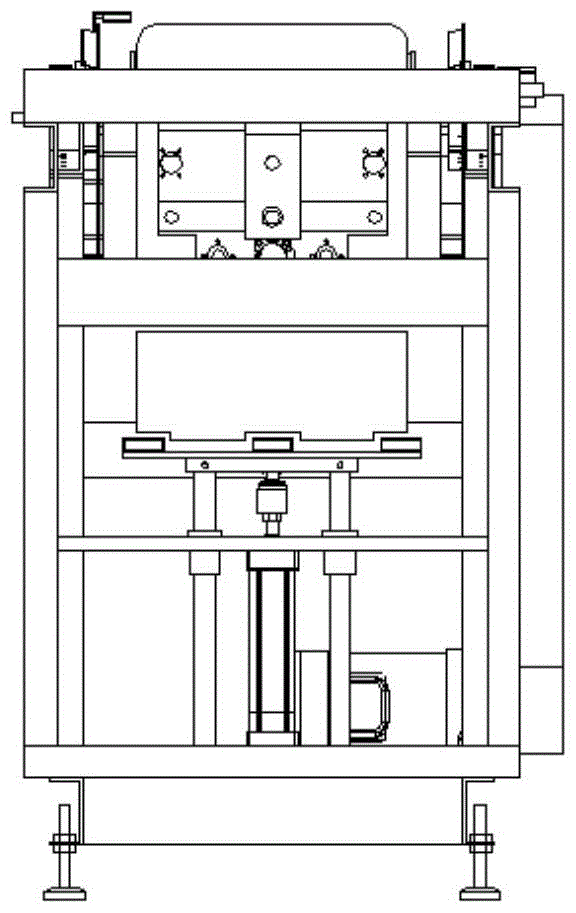

[0021] Attached below Figure 1-8 The present invention is further described.

[0022] Such as Figure 1-8 As shown, three-phase asynchronous AC motor (1), conveyor belt (2), buffer rod cylinder (3), photoelectric detection switch (4), buffer rod (5), buffer rod (6), buffer rod cylinder (7), Shaping stacking cylinder (8), carpet shaping stacking platform cylinder (9), carpet shaping stacking platform (10), carpet translation push plate (11), carpet translation push plate cylinder (12), carpet baffle plate (13), carpet shaping Fixed plate (14), carpet shaping movable plate (15), plastic stacking cylinder (16), carpet shaping movable plate (17), carpet shaping fixed plate (18), frame (19).

[0023] The carpet baffle (13) is set on both sides of the conveyor belt (2). When the power is turned on, the three-phase asynchronous AC motor (1) drives the conveyor belt (2) to convey the carpet, and the motor speed is controlled by the frequency converter, thereby controlling the speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com