Saucer for vehicle

A technology for cup holders and vehicles, applied in vehicle parts, special positions of vehicles, transportation and packaging, etc., can solve the problems of insufficient horizontal installation space, unable to achieve normal placement of cups, etc., and achieve the effect of reducing horizontal installation distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

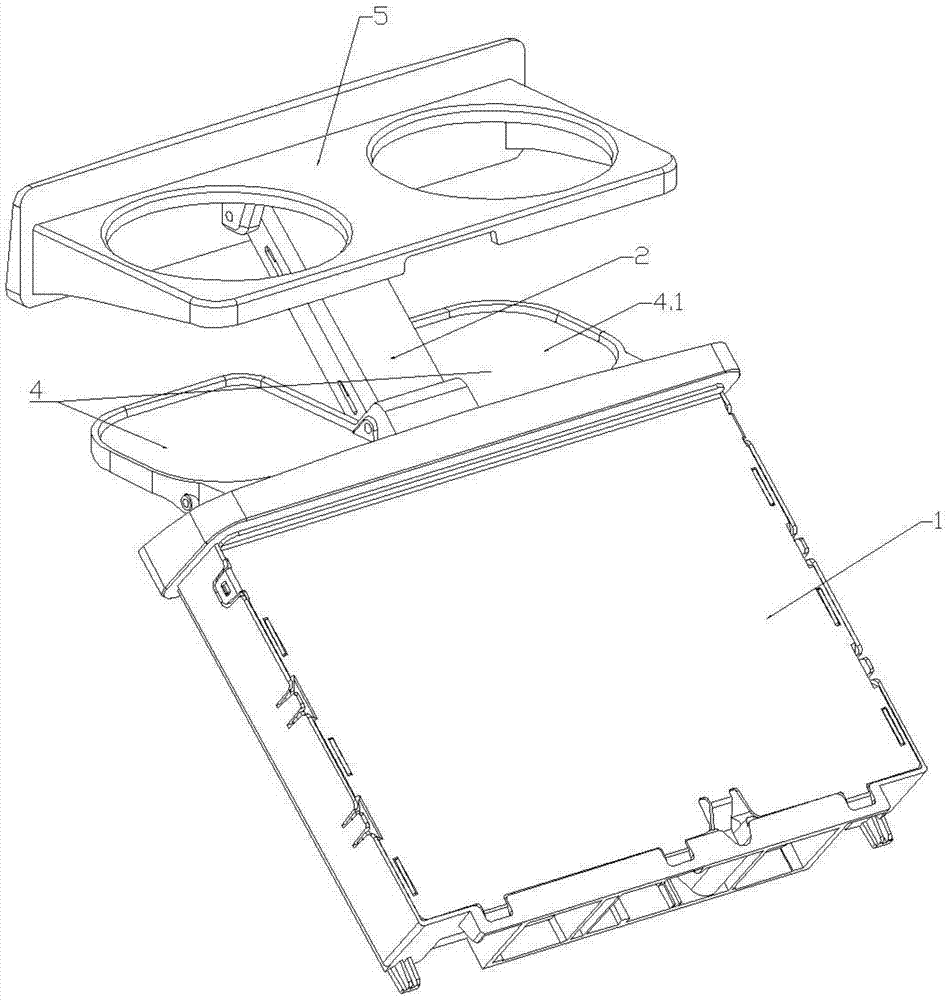

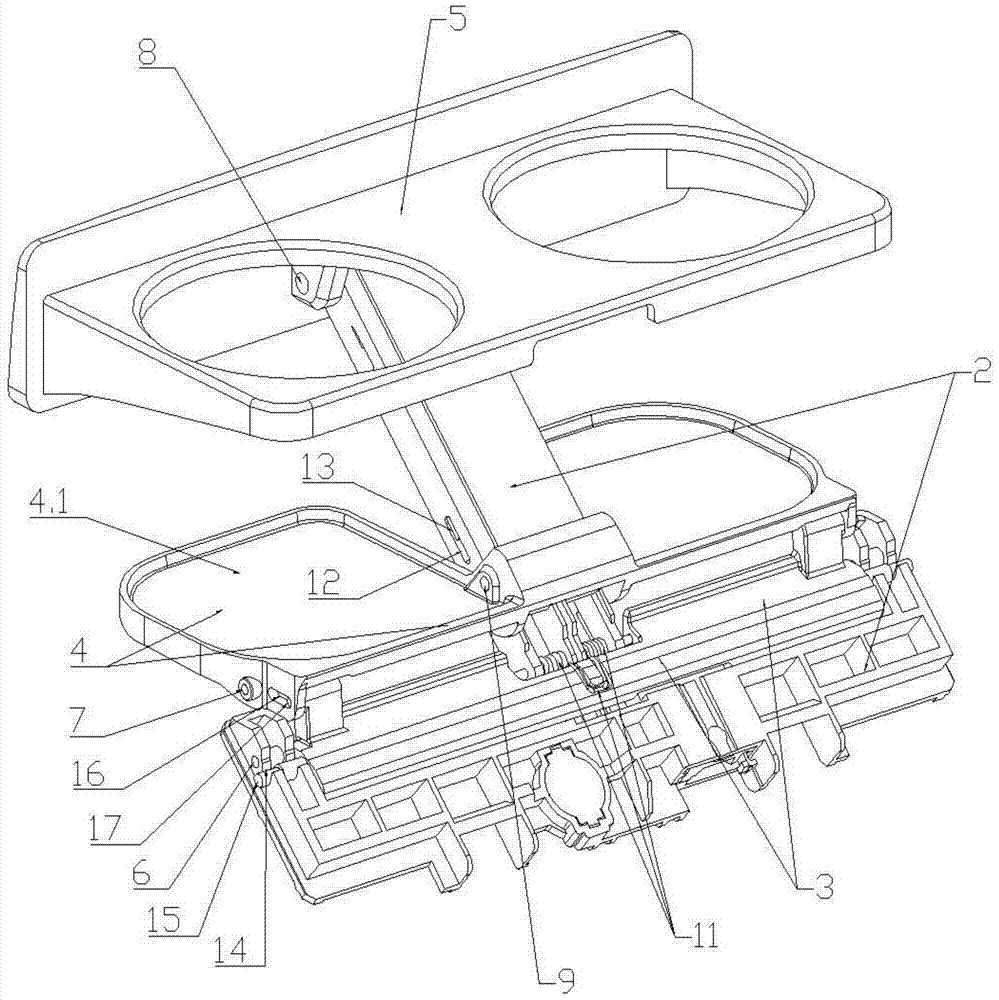

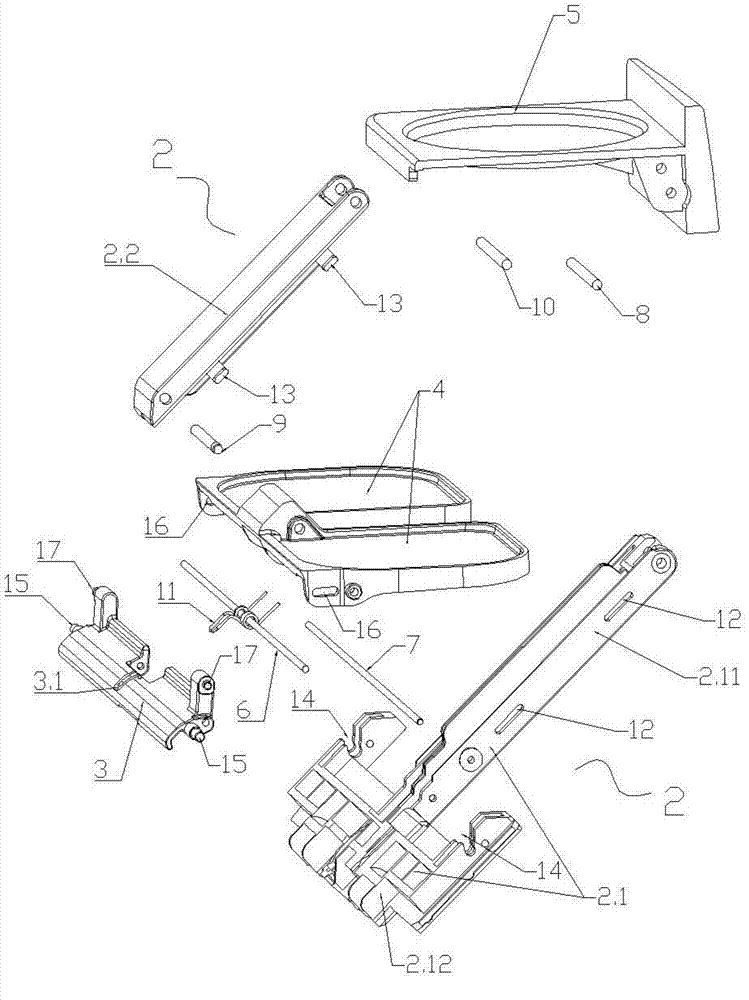

[0014] As shown in the figure, a cup holder for a vehicle includes a housing 1 and a bracket mechanism. The bracket mechanism includes a cup holder bracket 2 , a hinge 3 , a tray body 4 and a cup ring bracket 5 .

[0015] Different from the prior art, the cup holder bracket 2 is composed of a lower sliding rod 2.1 that is slidably fitted in the housing 1 and an upper moving rod that moves back and forth a preset distance along the longitudinal beam 2.11 of the lower sliding rod 2.1 through the sliding structure 2.2 Composition. Wherein, the lower sliding bar 2.1 also includes a crossbeam 2.12 in addition to the longitudinal beam 2.11, and the longitudinal beam 2.11 and the crossbeam 2.12 are an integral structure, and the whole is a T-shaped structure. In addition, the preset distance that the upper moving rod 2.2 moves back and forth along the longitudinal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com