A composite material-based automatic pitch propeller determination method

A composite material and method-determined technology, applied to propellers, aircraft parts, transportation and packaging, etc., can solve the problems of occupying the carrying capacity of aircraft, increasing the weight of high-power motors, and low air density, so as to reduce flight uncertainty and improve Utilization efficiency and effects of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

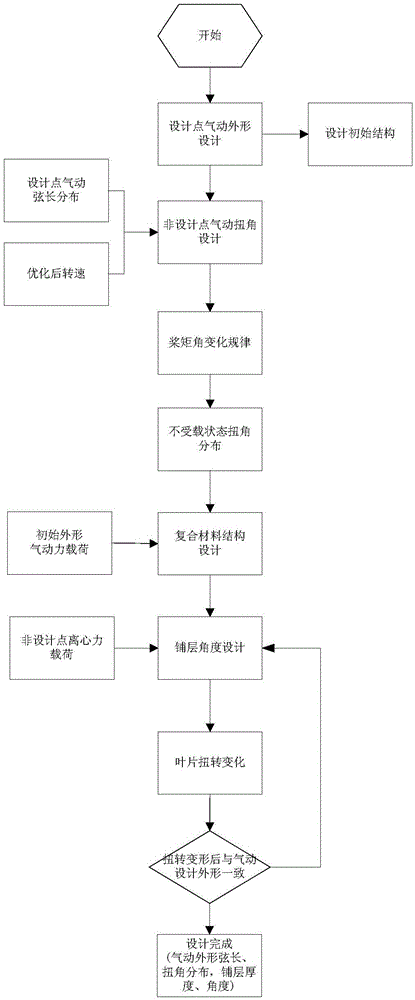

[0025] Propellers are an important part of the propulsion system of solar-powered vehicles in near space. In order to prolong the space time of solar-powered aircraft at high altitude, special propellers designed for high-altitude environments are generally used, and in order to reduce weight and improve reliability, fixed-pitch propellers are generally used. The torsion angle distribution of the fixed-torque propeller is fixed, that is, its aerodynamic shape is fixed. The fixed-pitch propeller designed for high altitude can achieve high efficiency at high altitude, which can meet the requirements of high altitude flight. But at medium and low altitudes, due to the increase in air density, the flight speed of the solar-powered aircraft decreases, and the speed of the propeller also decreases. Due to the high air density, the input power of the propeller is very large, and there is a problem in matching with the motor at this time. In order to meet the requirements of propell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com