Ball pin toggle ball joint three-dimensional axis

A ball pin, three-dimensional technology, applied in the field of three-dimensional axis of the ball pin toggle type ball joint, to achieve the effect of strong practical value, ingenious mechanism, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

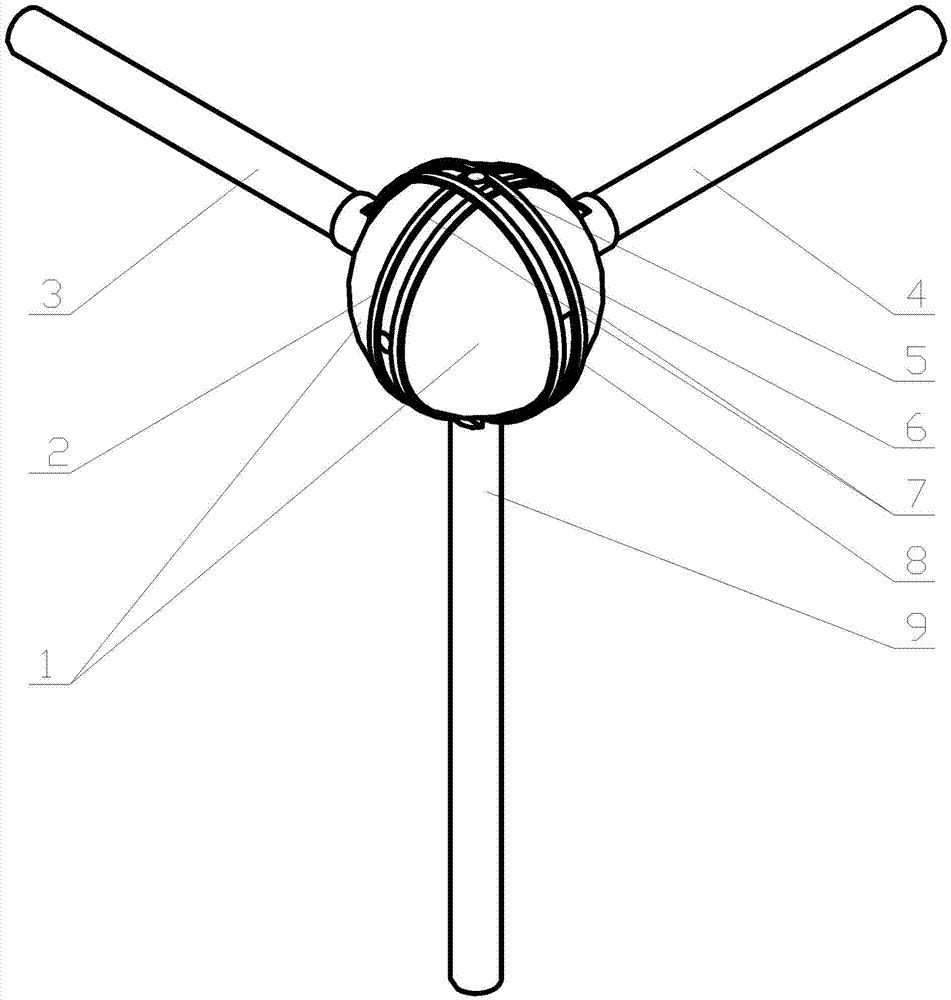

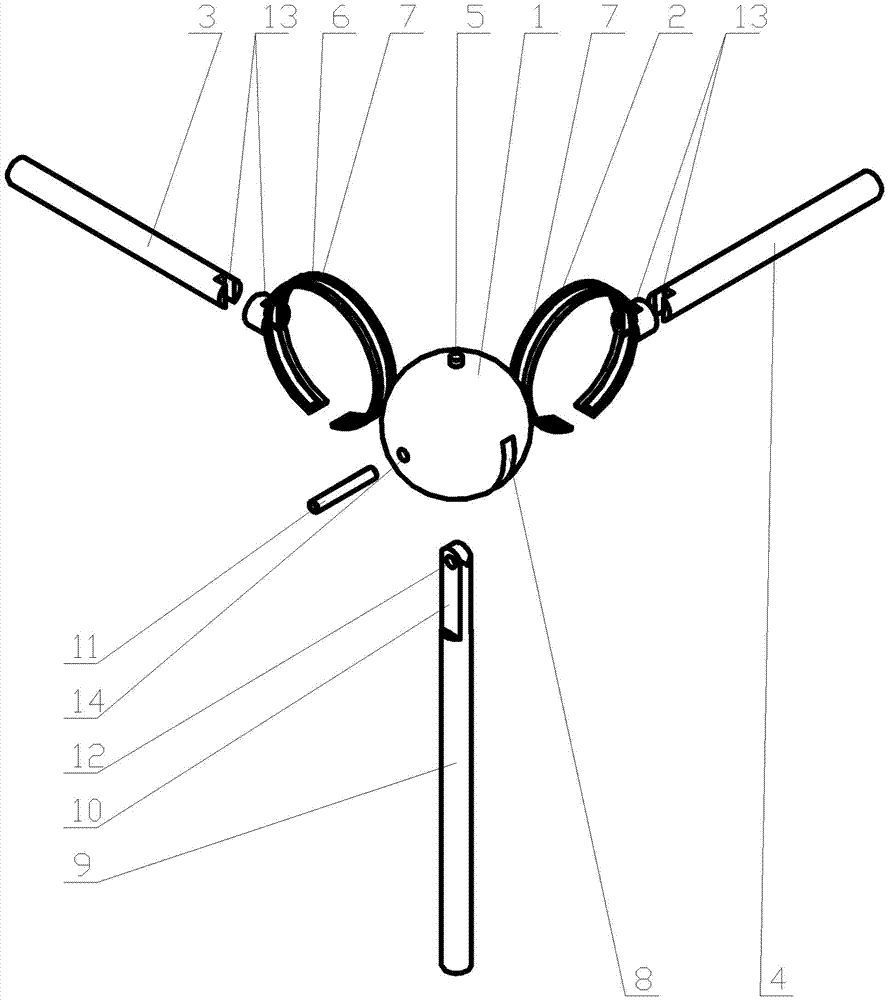

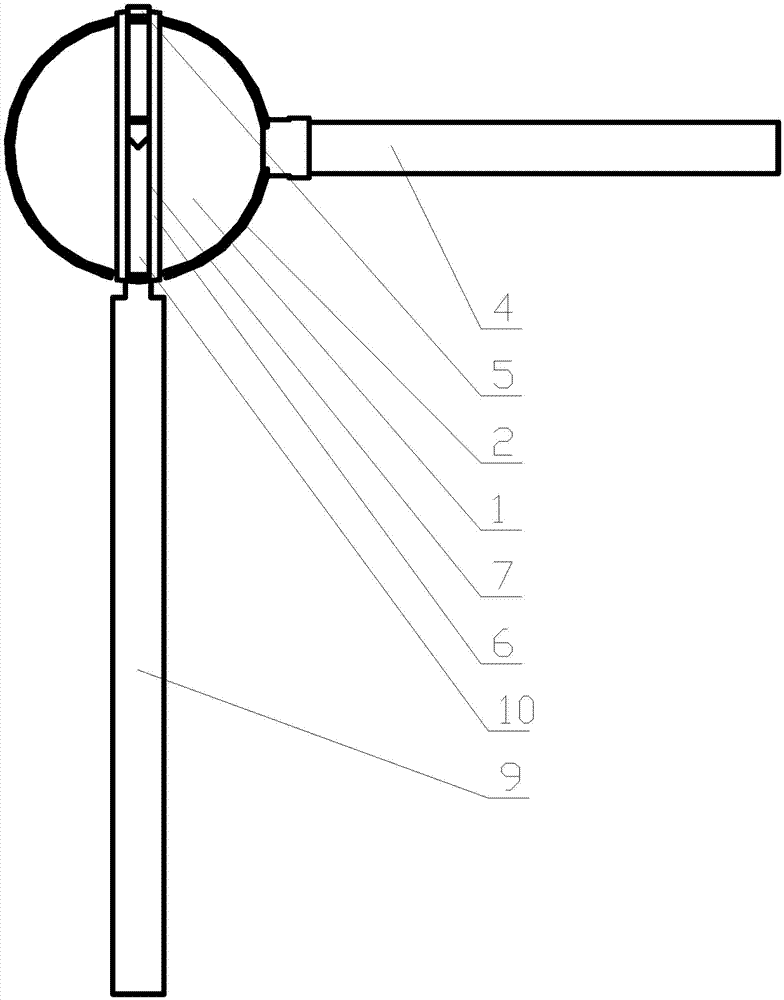

[0024] exist Figure 1 to Figure 4 Among them, it represents the structural composition of the present invention and the connection and positional relationship of parts. The three-dimensional axis of the ball-pin toggle type ball joint includes a ball 1, a ball pin 5, an inner arc-shaped slideway 2, an outer arc-shaped slideway 6, and an X-axis 4. Y-axis 3, Z-axis 9 and pin 11; ball 1 is provided with ball pin 5, Z-axis chute 8 and ball pin hole 14, ball pin 5 is cylindrical, fixedly connected to sphere 1, and Z-axis slides The slot 8 is a transparent square slot, the ball pin hole 14 is a transparent cylindrical hole through the center of the sphere 1, the square slot is perpendicular to the ball pin hole 14; the Z axis 9 is placed vertically, and the upper end of the Z axis 9 is set as the Z axis The slider head 9, the two sides of the Z-axis slider head 9 contact the two sides of the Z-axis chute 8 on the sphere 1 and form a clearance fit; the Z-axis slider head 9 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com