Electrowetting micro-fluid device based on super-hydrophobic surface

A microfluidic device and superhydrophobic surface technology, applied in the chemical/physical/physical chemical process of applying energy, etc., can solve the problem that water droplets cannot automatically recover, achieve reliable hysteresis reduction characteristics, improve fluid displacement rate, and fast control speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

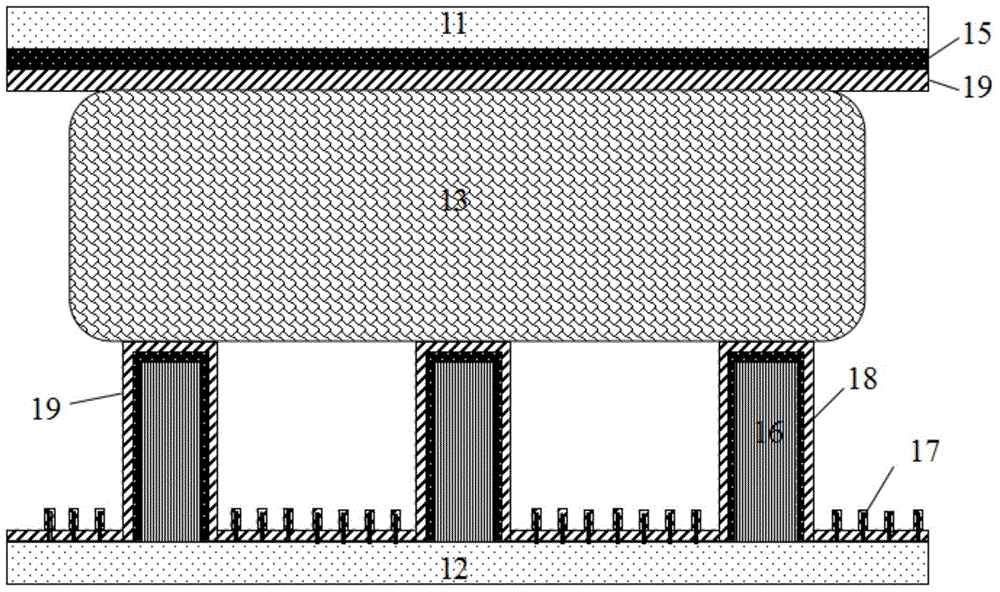

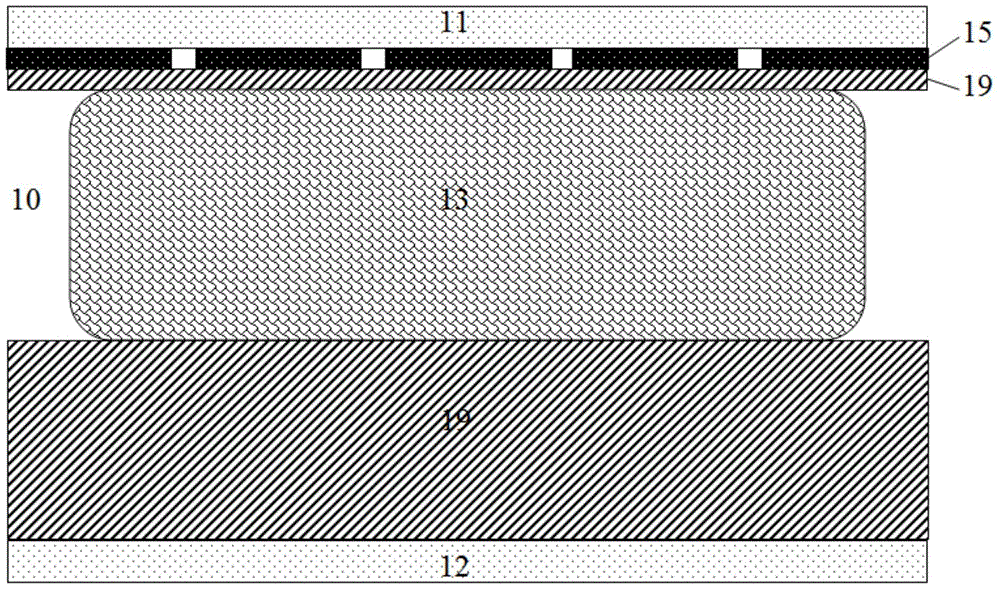

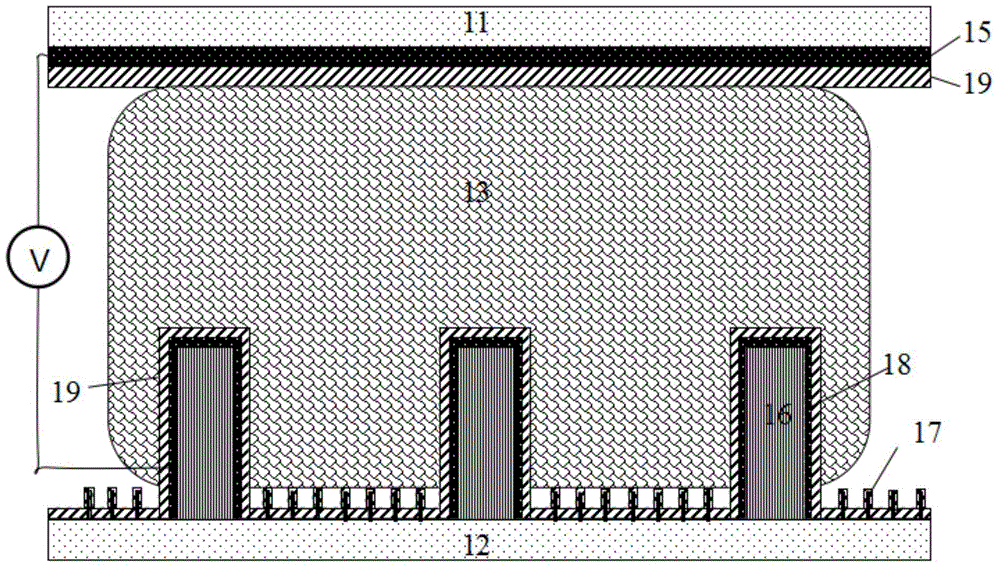

[0018] Such as figure 1 , figure 2 Shown is an electrowetting microfluidic device based on a superhydrophobic surface, including a microfluidic-manipulated lower substrate 12, a microfluidic-manipulated upper substrate 11, and a microfluidic microfluidic device between the lower substrate 12 and the upper substrate 11. A cavity 10, the microfluidic cavity 10 is an aqueous microfluid 13, the upper surface of the lower substrate 12 is provided with a micro-nano double structure; A group of micron-scale strip structures 16 on the surface, the surface of the strip structure 16 is covered with a layer of conductive layer 18, and the surface of the conductive layer 18 is covered with a layer of hydrophobic medium layer 19; The nanostructures include a nanoscale structure array 17 arranged on the upper surface of the lower substrate 12, the surface of the structure array 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com