Large-scale ring polishing machine workpiece carrying transportation vehicle

A technology of transport vehicles and ring throwing machines, which is applied in the direction of motor vehicles, transportation and packaging, trolleys, etc., can solve problems such as unfavorable workpiece surface finish indicators, achieve the effects of reducing the source of impurities, convenient operation, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0016] The present invention will be further described below in conjunction with the embodiments and drawings, but the scope of the invention should not be limited by this.

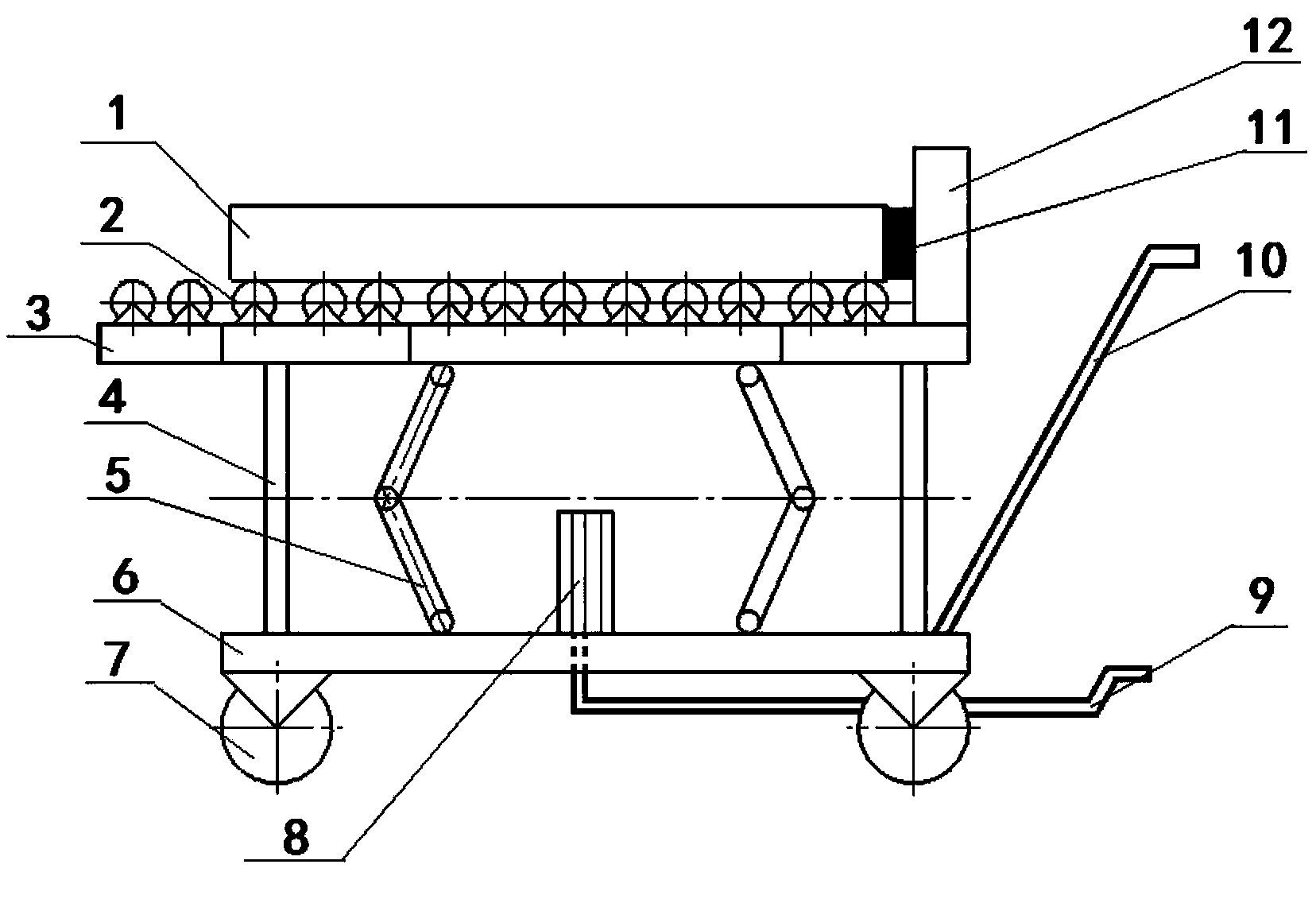

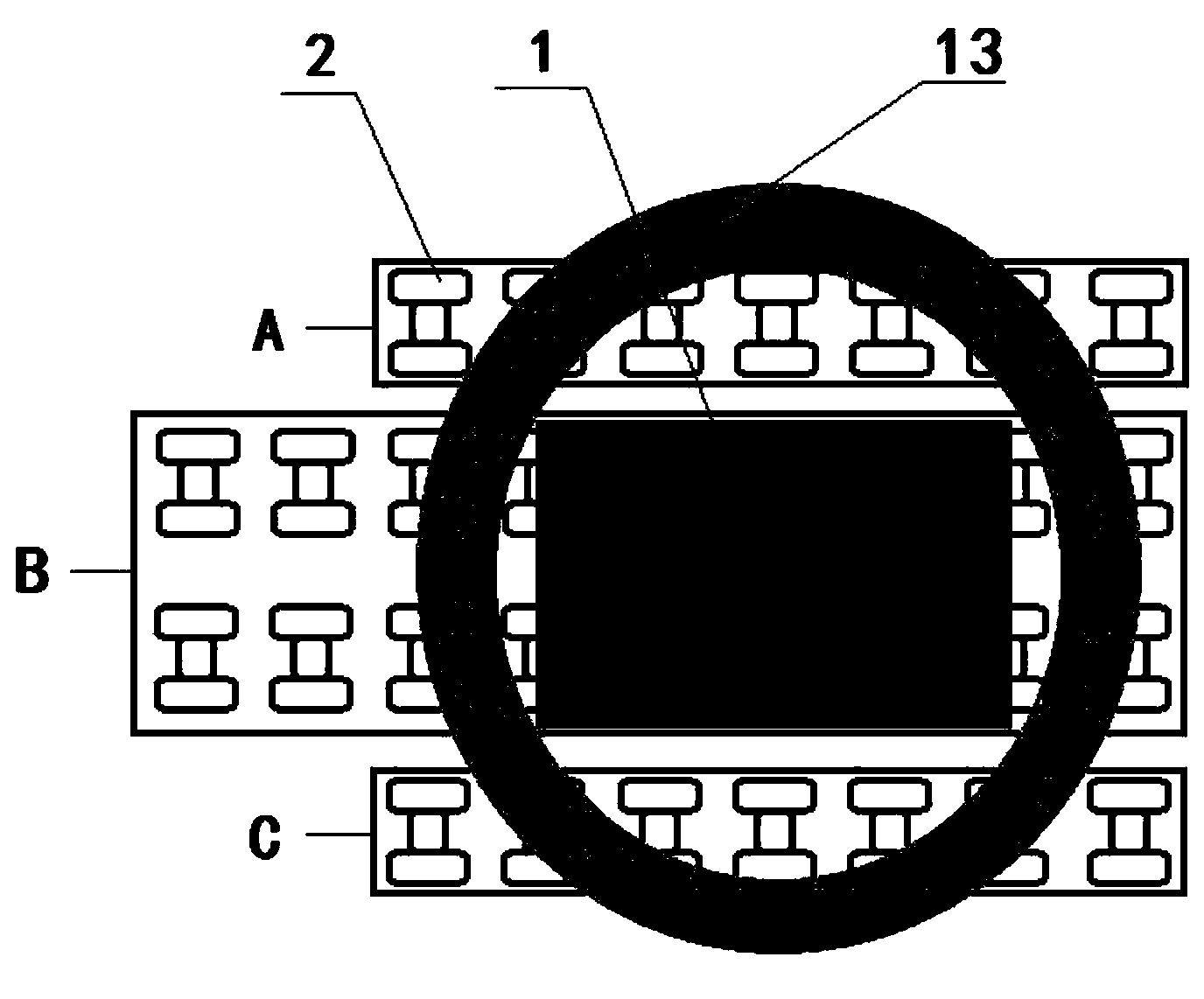

[0017] See first figure 1 , figure 1 It is a schematic structural diagram of the best embodiment of the workpiece carrying device of the large ring polishing machine of the present invention. It can be seen from the figure that the large ring polishing machine workpiece carrying transport vehicle of the present invention includes an aluminum alloy bottom plate 6, and the bottom plate is equipped with Four universal wheels 7 and a brake device. The upper end of the bottom plate is provided with a push handle 10, a hydraulic lift 8 and a telescopic lifting rod mechanism 5. When in use, the lifting of the telescopic lifting rod mechanism 5 is realized by applying pressure to the pedal 9 with your foot ; The support frame 3 is equipped with rubber rollers 2, which can realize the feeding and withdrawal of the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com