Guide faller

A needle plate and guiding technology, which is applied in the direction of textiles and papermaking, sewing equipment, sewing machine components, etc., can solve the problems of inaccurate direction control, low production efficiency, and inability to control sewing routes well, so as to reduce labor intensity and improve The effect of production efficiency and beautiful product stitches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

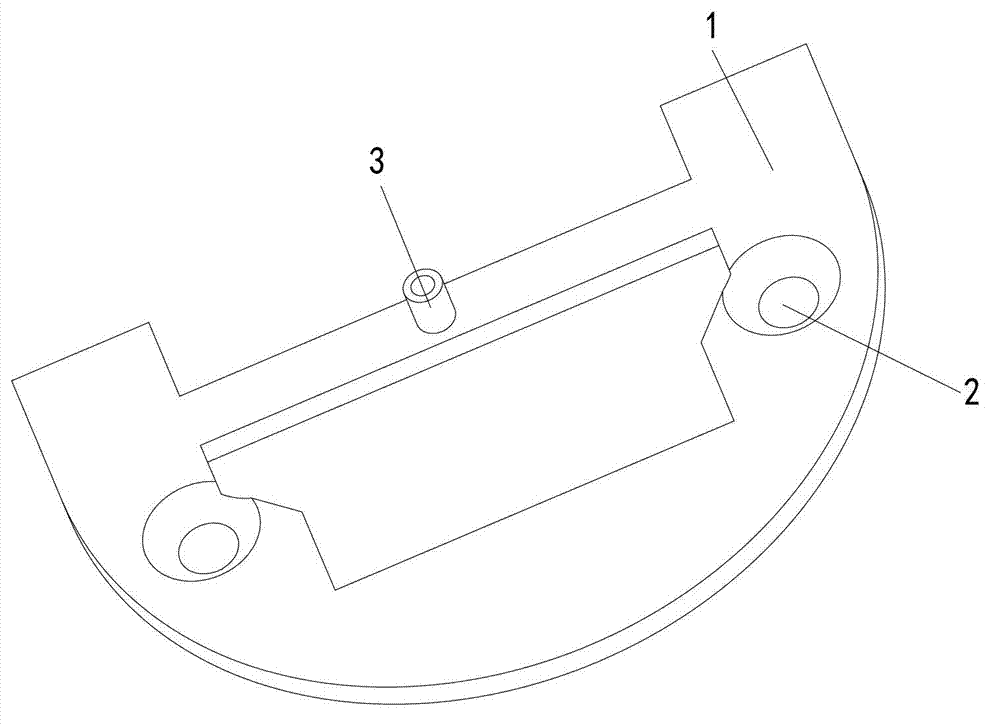

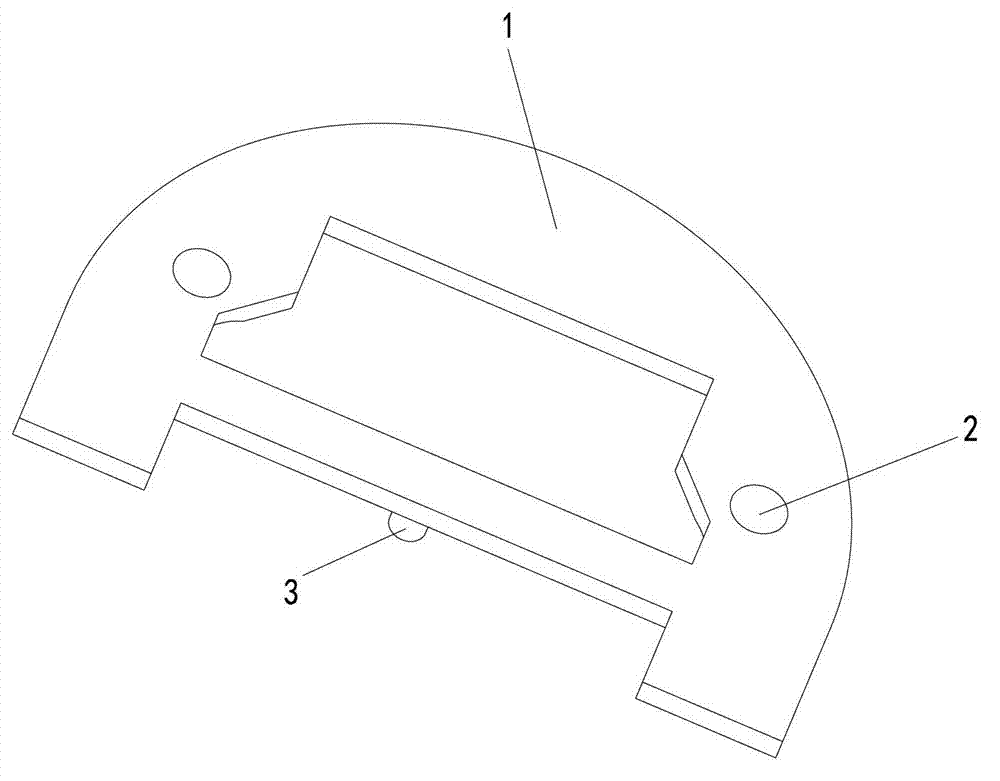

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] as attached Figure 1-2 The illustrated needle plate guide of the present invention includes a needle plate body 1, on which a plurality of mounting holes 2 are provided; on the needle plate body 1, guide columns 3 are provided; The number of mounting holes 2 is two.

[0014] In the guide needle plate of the present invention, a guide column is added on the needle plate, so that when the sewing machine sews through the template, the guide column can just be stuck in the template, thereby playing a guiding role, so that the sewing machine can accurately follow the The direction of the template is sewn, which reduces the labor intensity of the workers and improves the production efficiency. The processed products have beautiful stitches and are suitable for large-scale batch applications.

[0015] The above-mentioned embodiments are only to illustrate the technical conception and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com