Seal performance comprehensive testing device for deep lunar soil seal assembly

A comprehensive testing and sealing technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of inconvenient collection and research of deep lunar soil, no sealing components, etc., achieve smooth collection and research, simple structure, and easy implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Specific implementation mode one: combine Figure 1-Figure 3 , Figure 5-Figure 7 Describe this embodiment mode, a kind of sealing performance comprehensive testing device that is used for deep lunar soil sealing assembly of this embodiment comprises sealing environment simulation module A, sealing force application and testing module B and sealing destructive force application and testing module C, sealing force The applying and testing module B and the sealing destructive force applying and testing module C are both set on the sealing environment simulation module A,

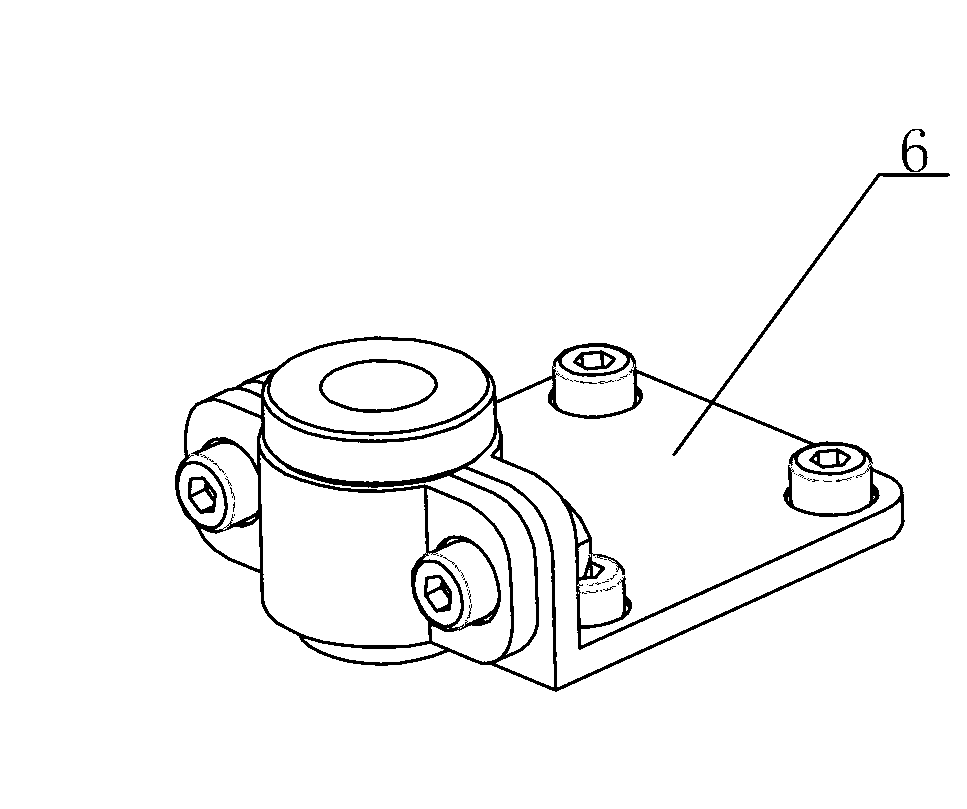

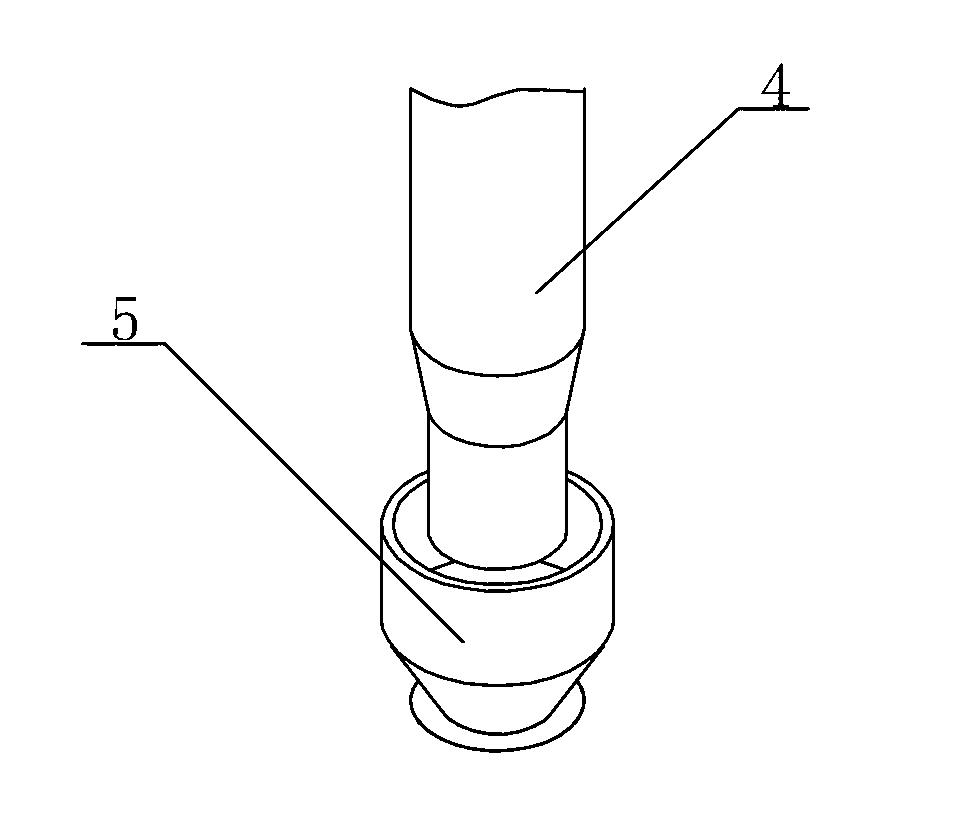

[0015] The sealing environment simulation module A includes a mounting plate 1 on the test bench, a mounting plate 2 under the test bench, a test bench support 3, a soft bag 4, a lunar soil flow rate regulating cup 5 and a lunar soil filling port joint 6, and the mounting plate on the test bench 1 and the lower mounting plate 2 of the test bench are arranged in parallel from top to bottom, the test ben...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination Figure 4 To illustrate this embodiment, each group of sealing force applicators in this embodiment includes a sealing force mounting plate 13, a bracket 14, a code disc 15, a motor 16, a reducer 17, a coupling 18, a lead screw 19, and a universal conversion block 20. Sealing force slider 21, sealing force guide rail 22, 75mm displacement sensor 23 and sealing tension sensor 24, sealing force mounting plate 13 is set on the mounting plate 2 under the test bench of sealing environment simulation module A, and bracket 14 is set on the sealing force On the mounting plate 13, the speed reducer 17 is arranged on the support 14, one end of the speed reducer 17 is connected with the code disc 15 and the motor 16, the other end of the speed reducer 17 is connected with the coupling 18, and the sealing force slider 21 is arranged at the sealing force On the mounting plate 2 under the test bench of the sealing environment simulation m...

specific Embodiment approach 3

[0019] Specific implementation mode three: combination Figure 4 To illustrate this embodiment, each group of sealing force applicators in this embodiment further includes a guide rail dust cover 25 , and the guide rail dust cover 25 is mounted on the sealing force guide rail 22 . Such arrangement effectively prevents the sealing force guide rail 22 from dusting. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com