Soft food 3D (three-dimension) printing system

A 3D printing and food technology, applied in the field of flexible food 3D printing system, can solve the problems such as the difficulty of using 3D printing technology for flexible substances such as liquids and gels, the limitation of rapid design, promotion and application of 3D printing technology, and the inability to form effectively. Improve user experience, rapid prototyping, and enhance enjoyment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

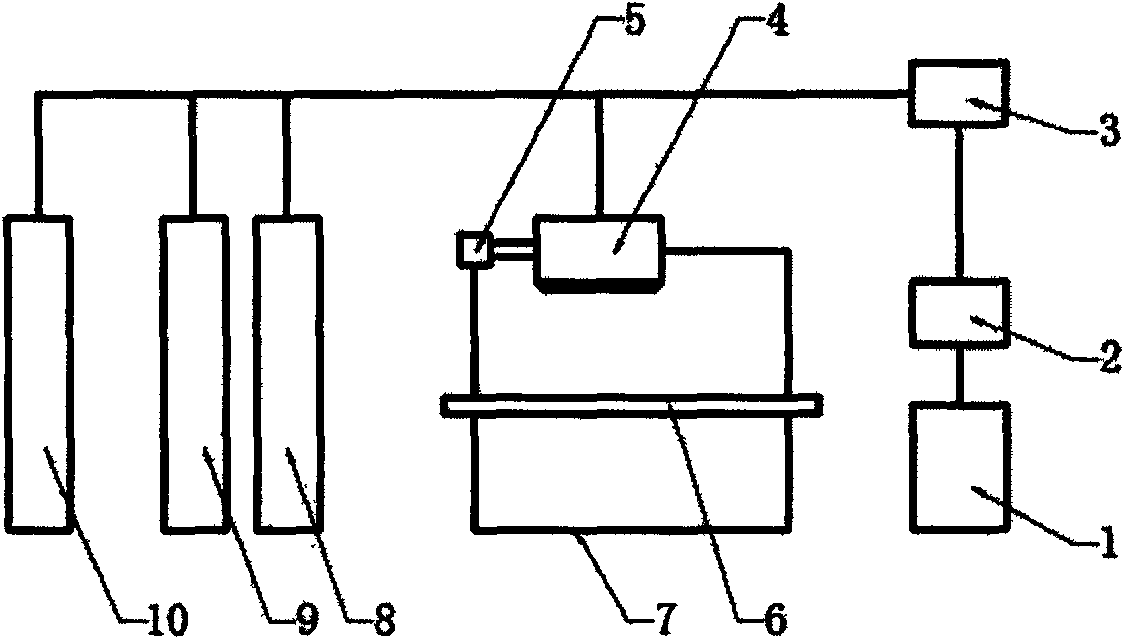

[0033] A flexible food 3D printing system, the components include a user operation interface (1) and system software (2), an integrated controller (3), an injection molding module (4), a horizontal positioning module (5), a normal positioning module (6 ), a support frame (7), a temperature control module (8), an intelligent cleaning module (9), and a raw material supply module (10).

[0034] The user operation interface (1) is a Window Surface computer operating system.

[0035] The injection molding module (4) is composed of 16 mutually independent injection circular pipes and their flow pumps, and the diameter of the pipes is 0.10 mm.

[0036] The injection molding module (4) and all connecting pipes are designed and constructed for easy disassembly.

[0037] The temperature control module (8) controls the temperature from -10°C to 50°C with an accuracy not lower than 0.1°C.

[0038] The raw material supply module (10) is composed of 16 mutually independent containers and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com