Gravity-type combined rail-type wheel-axle three-dimensional warehouse

A three-dimensional warehouse and track-type technology, applied in the field of three-dimensional warehouses, can solve the problems of high storage costs, large floor area, and high operating costs of automated three-dimensional warehouses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

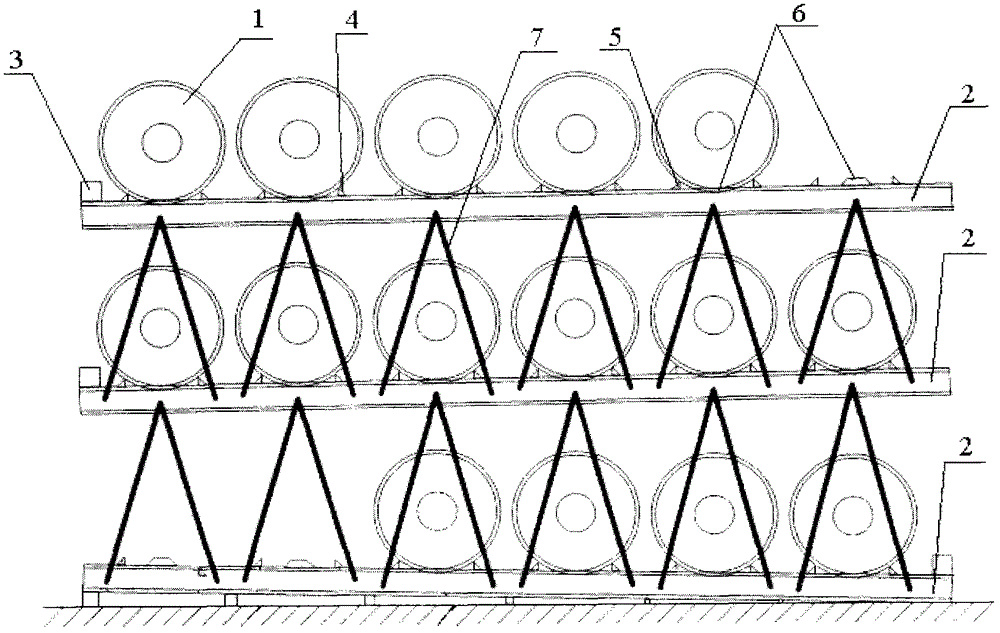

[0027] Such as figure 1 As shown, the gravity-type combined track-type axle three-dimensional warehouse includes 1 to 50 layers of axle racks and several axle storage positions evenly distributed on the axle racks. Each layer of the axle frame includes two parallel track-type axle frame long beams 2 that are placed in parallel and are provided with a slope relative to the horizontal plane along the length direction, and a wheel axle outlet fixed stopper 3 placed at one end of the track-type wheel axle frame long beam 2 and distributed in the Several axle storage positions on the long crossbeam 2 of the track-type axle frame; each of the several axle storage positions stores an axle 1; one end of each axle storage position is provided with a warehouse-in side axle stopper 4, and the other end There is a wheel shaft stopper 5 on the delivery side, and a cargo space center stopper 6 is arranged in the center; the fixed stopper 3 at the outlet of the wheel axle is in the same dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com