Non-contact online inspection method for automobile body gap size

A detection method, non-contact technology, applied in the direction of measuring devices, image enhancement, instruments, etc., can solve the problems of inconvenient portability, inability to meet online measurement, and easy to be affected by external factors, so as to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

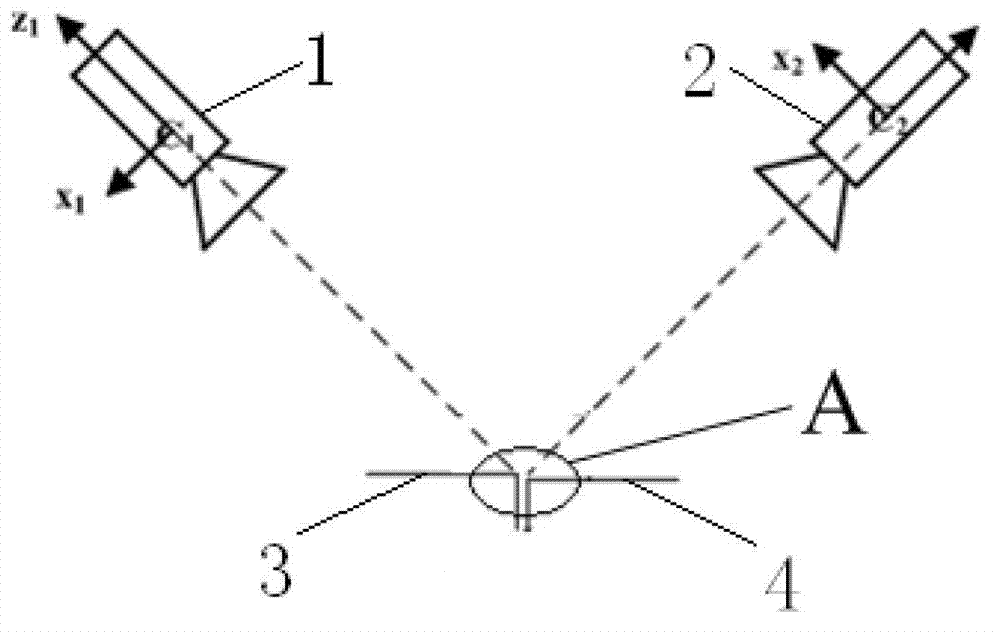

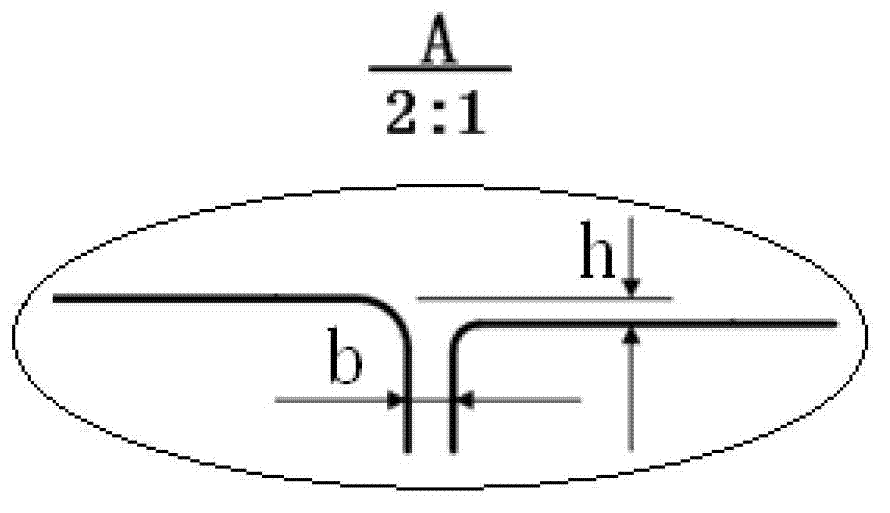

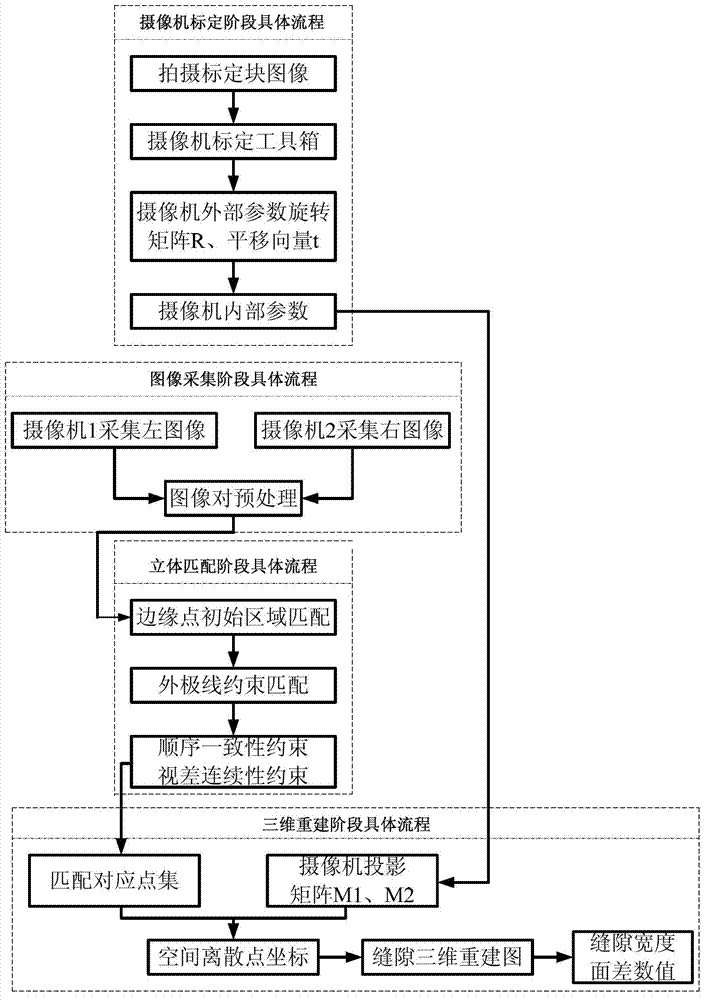

Method used

Image

Examples

Embodiment

[0192] 1. Camera calibration

[0193] 1. First run the Matlab software, add the path where the calibration toolbox is located to the Matlab path environment, and start the calibration main function calib-gui.m.

[0194] 2. Install the No. 1 camera and No. 2 camera in the appropriate position, and adjust the No. 1 camera and No. 2 camera to keep them still, constantly change the angle and orientation between the plane target and the imaging plane, and keep the plane target When the target is not moving, use the No. 1 camera and the No. 2 camera to take images of the plane target, and take an image every time the angle and orientation are changed, and a total of 15 images are taken. The images can be stored through the supporting image acquisition card in the computer.

[0195] 3. Run the Calibration calibration program to get the calibration results of No. 1 camera and No. 2 camera, and run the Analyze error program to analyze the error of the calibration results. If the accur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com