Light-emitting device

A technology for light-emitting devices and light-emitting devices, which is applied in the direction of electrical components, electric solid-state devices, circuits, etc., and can solve problems such as non-compliant backlighting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings.

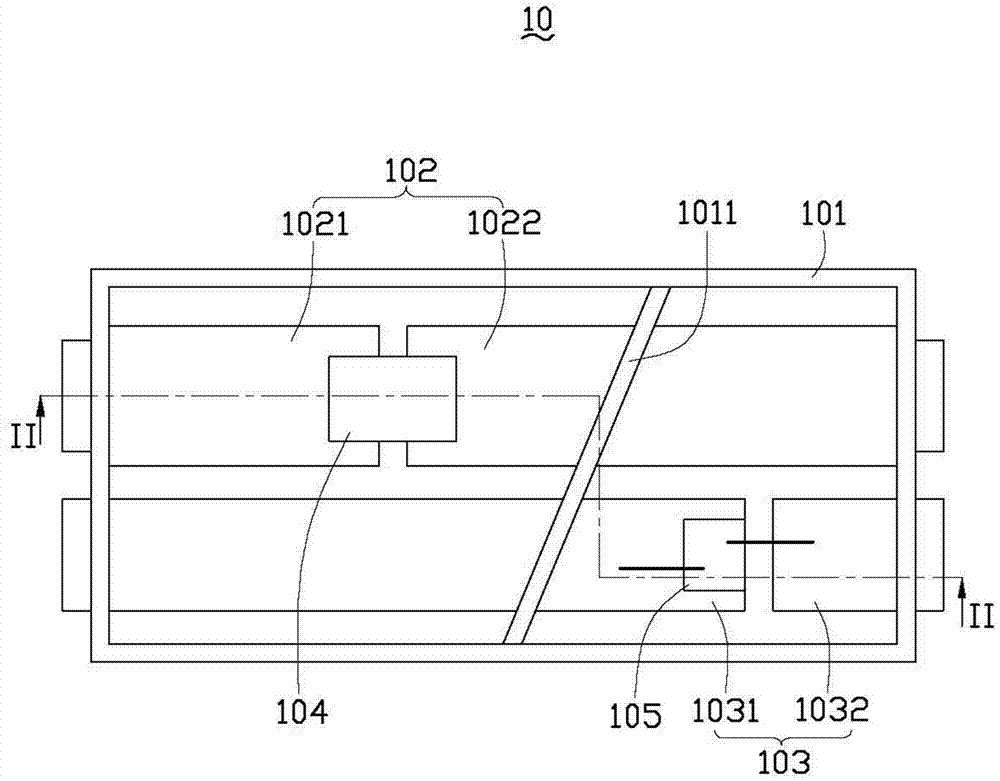

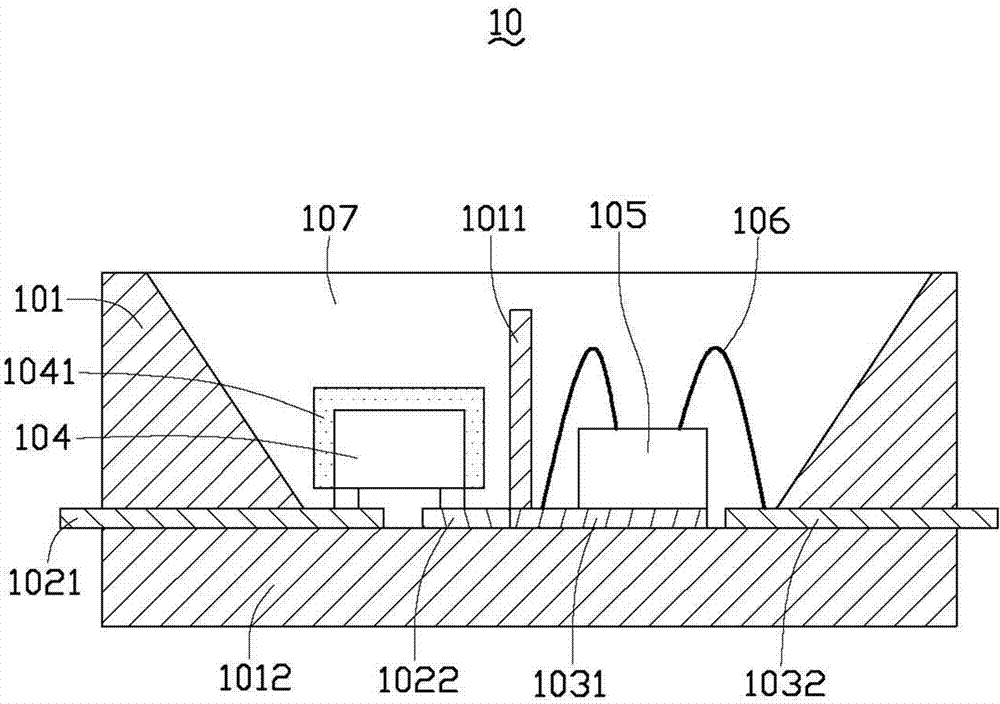

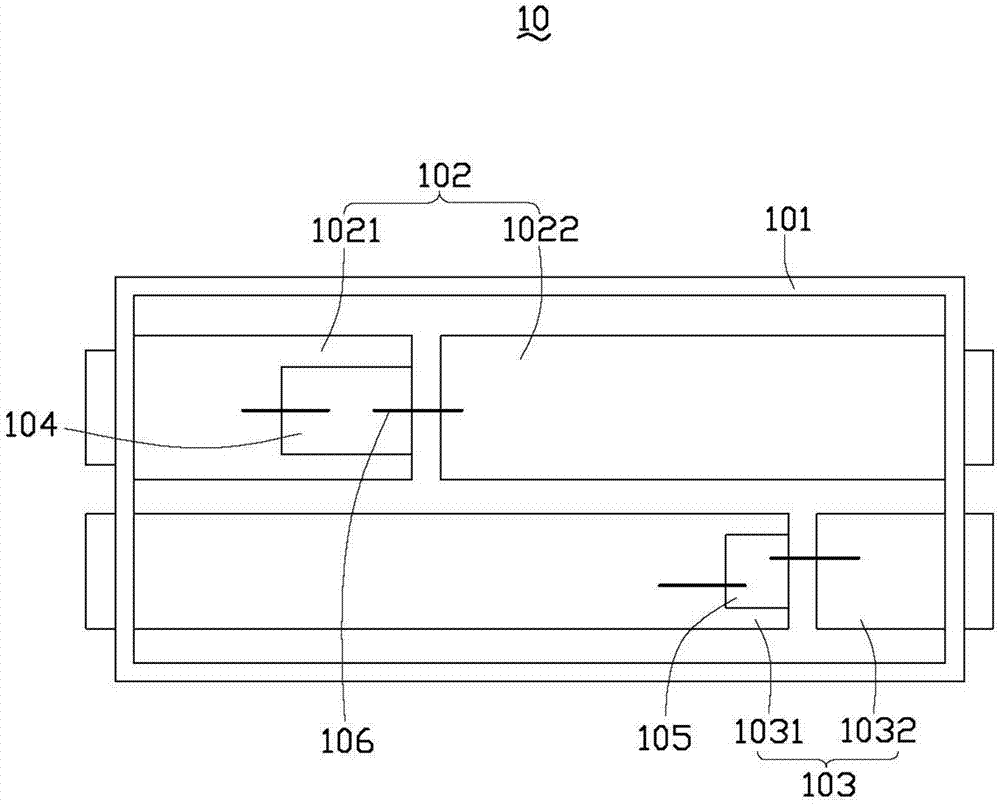

[0016] see Figure 1-2 , shows a top view and a cross-sectional view along line II-II of the light emitting device 10 according to the first embodiment of the present invention. In this embodiment, the light emitting device 10 includes a reflective cup 101 , a substrate 1012 , two conductive plates 102 , 103 , a first light emitting device 104 , a second light emitting device 105 , several wires 106 and a package 107 .

[0017] The substrate 1012 has a first surface and a second surface opposite to the first surface. Two conductive plates 102 and 103 are disposed on the first surface of the substrate 1012 . The conductive plates 102 , 103 are strip-shaped, and both are divided into first electrodes 1021 , 1031 and second electrodes 1022 , 1032 insulated from each other by openings. The first light emitting device 104 is mounted on the conductive plate 102 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com