Adjustable reactor with magnetic wedge

A technology for adjusting reactance and magnetic wedge, which is applied in the direction of continuously variable inductor/transformer, transformer/inductor coil/winding/connection, transformer/inductor core, etc. Convenience and other issues, to achieve the effect of simple and convenient adjustment, small vibration, reducing noise and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

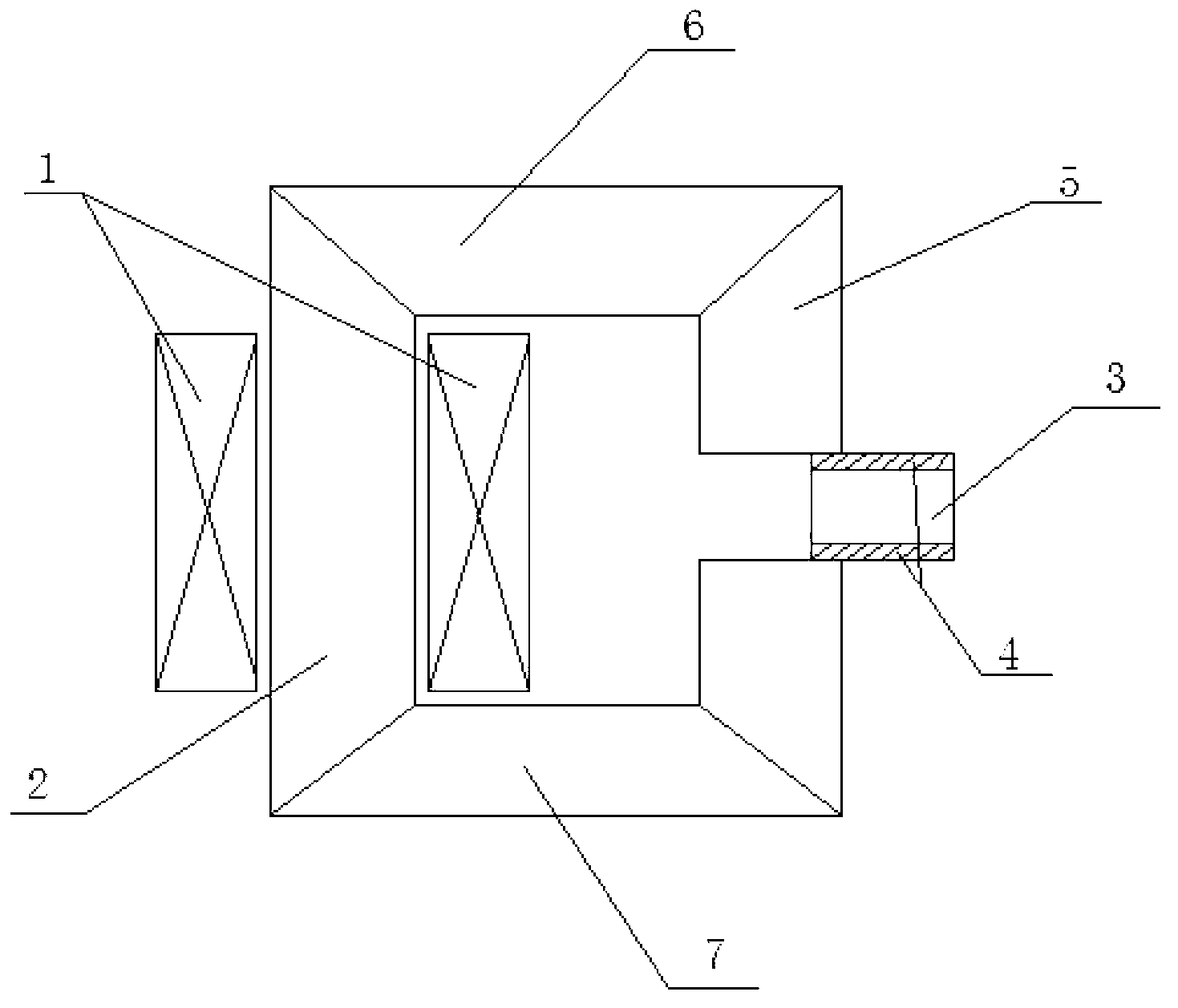

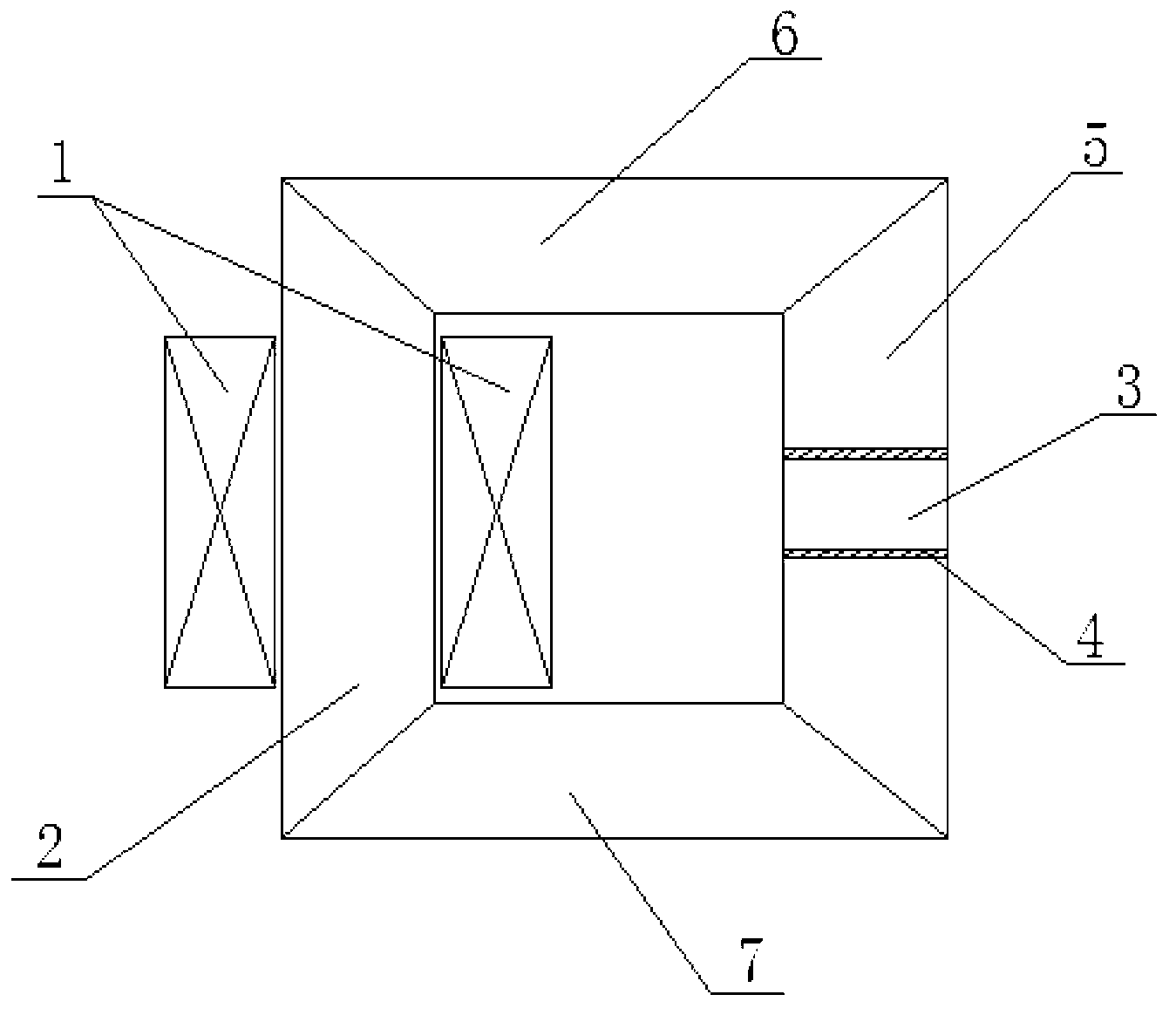

[0024] Specific implementation mode one: the following combination Figure 1 to Figure 8 Describe this embodiment mode. The magnetic wedge type adjustable reactor in this embodiment mode includes a rectangular main magnetic circuit composed of a winding core 2, a lower iron yoke 7, an air gap iron core 5 and an upper iron yoke 6 connected end to end in sequence. frame, which also includes an AC winding 1, a magnetic wedge 3 and two non-ferromagnetic insulating plates 4,

[0025] The lower iron yoke 7 and the upper iron yoke 6 are facing each other in the horizontal direction, and the AC winding 1 is spirally wound on the winding core 2. The center of the air-gapped iron core 5 is a horizontal air gap, and the magnetic wedge 3 is embedded in the horizontal air gap, and the magnetic wedge A non-ferromagnetic insulating plate 4 is arranged between 3 and the two side walls of the horizontal air gap, and the magnetic wedge 3 and two non-ferromagnetic insulating plates 4 are clamped...

specific Embodiment approach 2

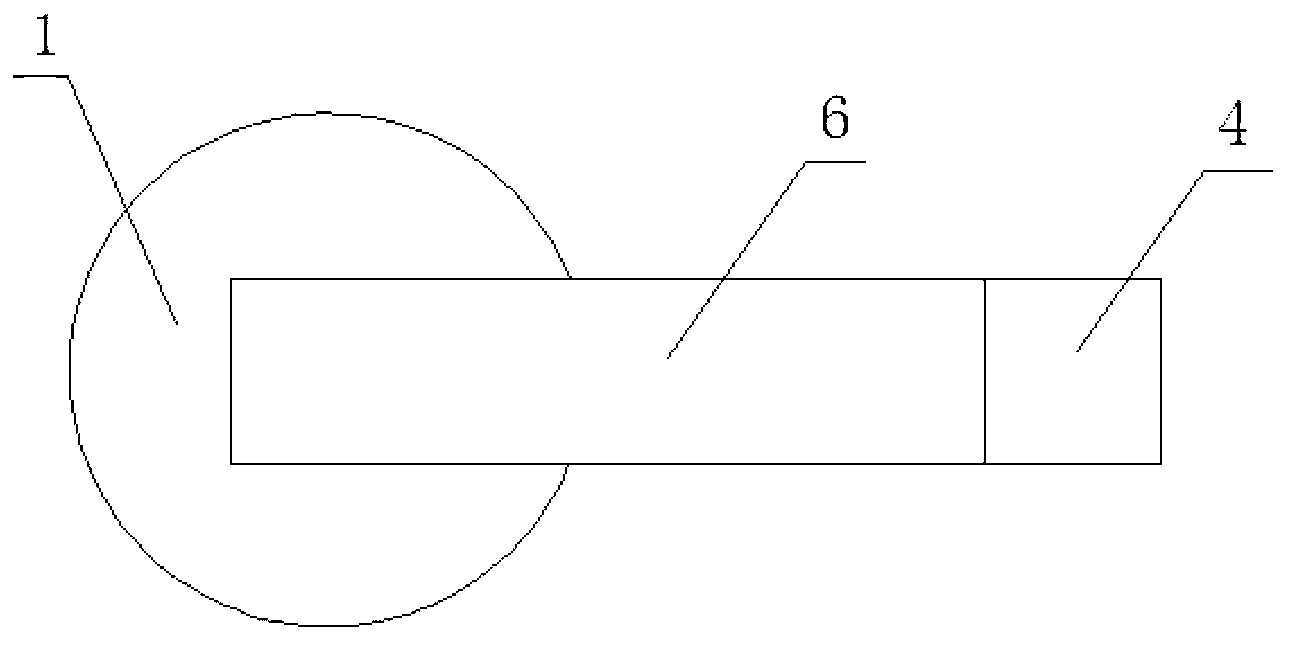

[0039] Specific implementation mode two: the following combination figure 2 This embodiment is described. This embodiment is a further description of Embodiment 1. The horizontal section of the AC winding 1 is circular or rectangular.

[0040] figure 2 The shown AC winding 1 has a circular cross-section, and it can also be wound into a winding with a rectangular cross-section.

specific Embodiment approach 3

[0041] Specific implementation mode three: the following combination Figure 9 and Figure 10 Describe this embodiment, the magnetic wedge type adjustable reactor in this embodiment includes a cylindrical core 8, it also includes an AC winding 1, a magnetic wedge 3 and two non-ferromagnetic insulating plates 4,

[0042] There is an axial air gap on the side wall of the cylindrical iron core 8, and the AC winding 1 is spirally wound on the cylindrical iron core 8. The winding direction of the AC winding 1 is parallel to the axial direction of the cylindrical iron core 8, and the magnetic wedge 3 is embedded In the axial air gap, a non-ferromagnetic insulating plate 4 is arranged between the magnetic wedge 3 and the two side walls of the axial air gap, the magnetic wedge 3 and two non-ferromagnetic insulating plates 4 Clamped in the axial air gap.

[0043] Figure 9 As shown, the magnetic circuit adopts a cylindrical iron core 8 structure, and the AC winding 1 is spirally wou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com