Pneumatic transfer platform

A platform and air motor technology, which is applied in the direction of turntable/moving platform, railway car body parts, transportation and packaging, etc., can solve the problems of mine cars that are prone to running cars and work-related injuries, and achieve safe transportation and low friction rate , the effect of high transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

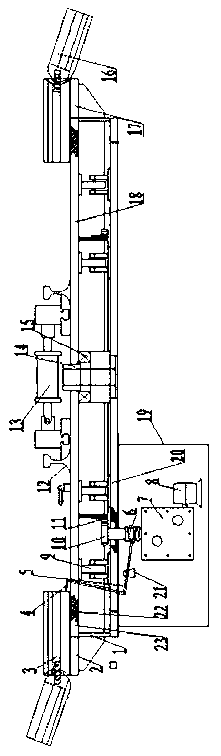

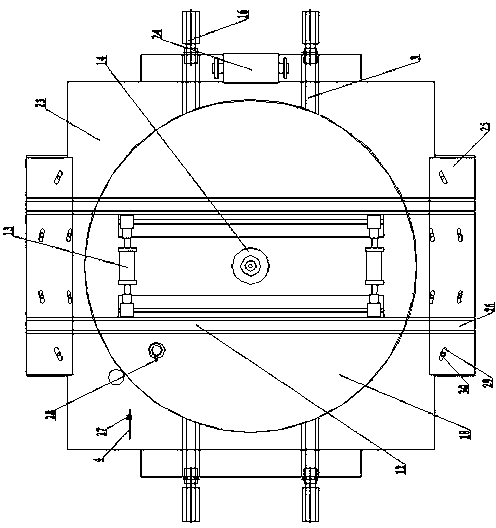

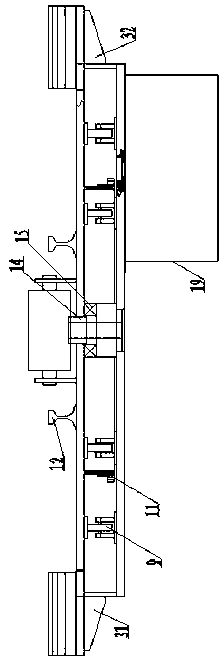

[0016] A kind of pneumatic transfer platform, see attached figure 1 to attach image 3 , in the figure: box 1, left seat 2, fixed track 3, handle 4, connecting rod 5, shift fork 6, reducer 7, air motor 8, roller set 9, driving gear 10, ring gear 11, Support rail 12, stopper 13, mandrel 14, bearing 15, moving rail 16, right seat 17, rotating disc 18, transmission box 19, base plate 20, support 21, dustproof ring 22, gland 23 , Ground roller 24, adjustable connecting plate 25, adjustable rail 26, handle support 27, rotating handle 28; arc groove 29, bolt 30, front seat 31, rear seat 32.

[0017] In this embodiment, the bottom of the box body 1 is connected with the transmission box body 19 equipped with the driving gear 10, and the roller wheel set 9 is housed in the box body 1, and the roller wheel set 9 is connected with the bottom plate 20 of the box body 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com