Printing synchronous embossing production device for leatherette paper

A technology for production equipment and binding paper, which is applied in printing, printing presses, rotary printing presses, etc., can solve the problem of high degree of manual participation, solve the problem of high degree of manual participation, reduce manual participation, and improve production efficiency and product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

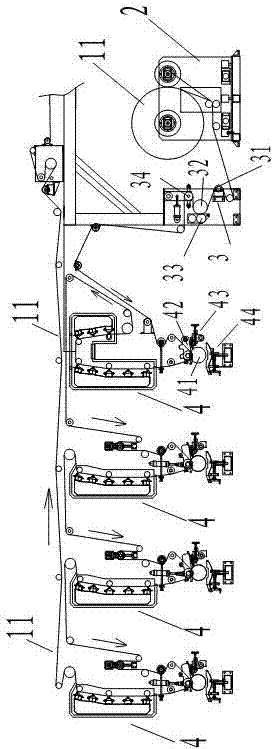

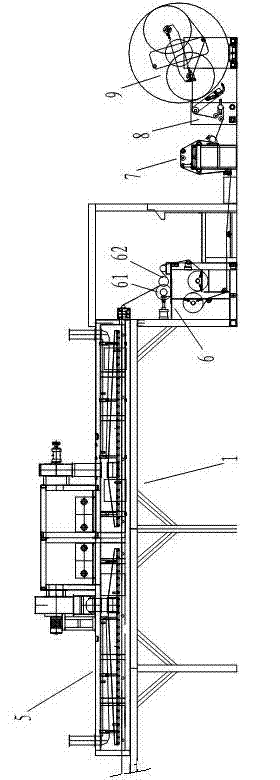

[0019] Such as figure 1 and figure 2 ( figure 2 catch figure 1 ) is shown in the structural schematic diagram of the synchronous sleeve press production equipment for binding paper printing in the present invention, which includes a frame 1, an unwinding machine 2, a feeding traction device 3, a printing machine 4, a foaming oven 5, an embossing machine 6, a cutting machine Side splitting device 7, material receiving traction device 8 and winder 9. The number of printing machines 4 can be set to multiple, and in this embodiment, the number of printing machines 4 is four. The printing press 4 is arranged on the lower left of the frame 1 . The unwinding machine 2 is arranged below the frame 1, at the feeding end of the printing mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com