Milk bag casing system

A packaging box and milk bag technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of low packaging efficiency, bruised milk bags, irregular arrangement, etc., to reduce labor intensity, fast packing speed, Neat packing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

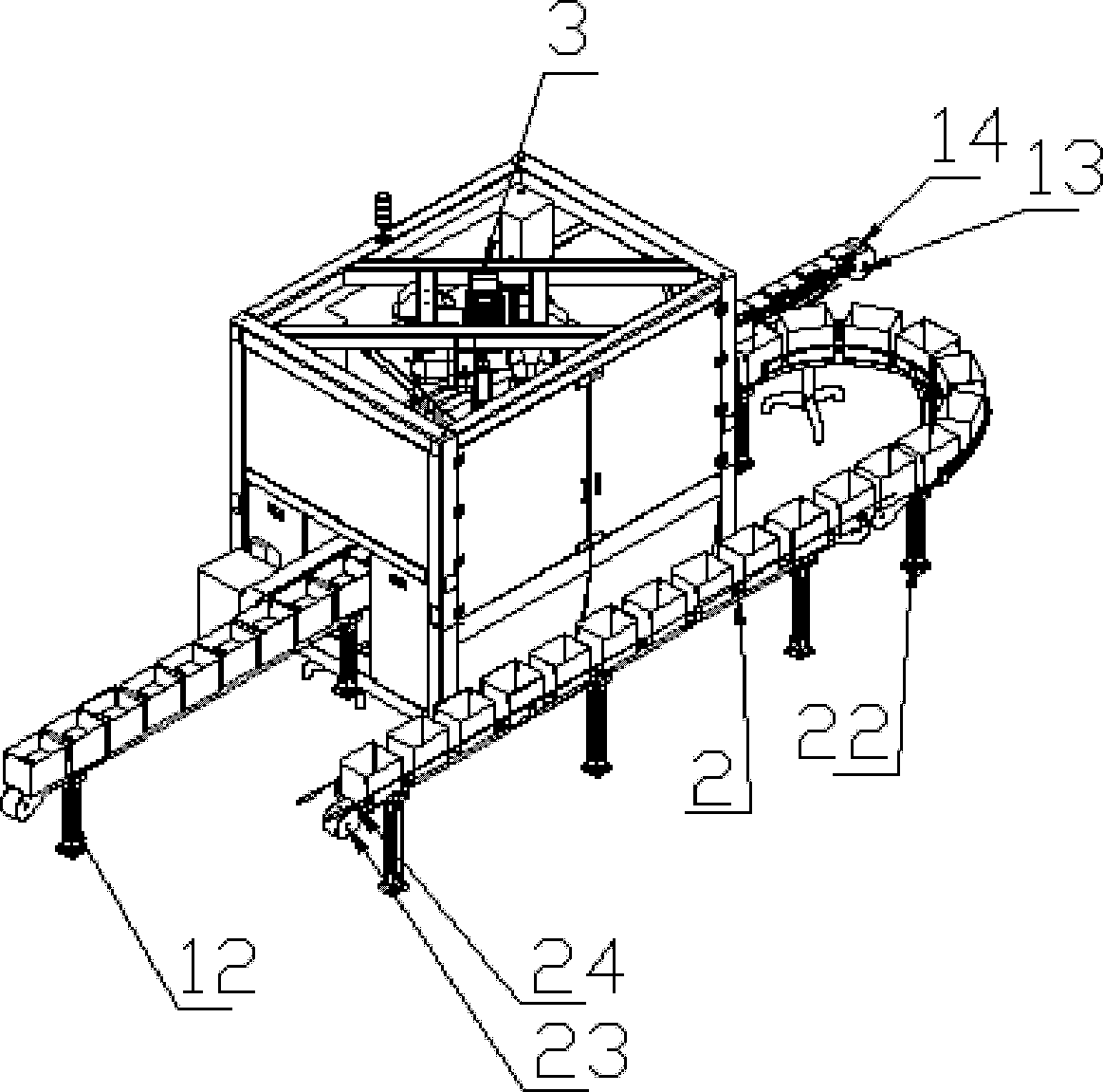

[0017] Embodiment: A milk packaging box system, including a milk bag conveying line 1, a packing box conveying line 2, a grabbing robot 3, a milk bag position sensing device, a packing box position sensing device and a controller, a milk bag conveying line 1 and a packing box The box conveying line 2 can drive the milk white and the packing box 21 to move respectively. Based on the direction of use, the milk bag conveying line 1 and the packing box conveying line 2 respectively pass through the position directly below at least one grasping robot 3, and the milk bag position sensing device and The packaging box position sensing devices are respectively installed on the milk bag conveying line 1 and the packing box conveying line 2 and can respectively sense the position of each milk bag 11 and each packing box 21 and transmit the sensing signal to the controller, which can control the grabbing robot 3 Grab a set number of milk packs 11 and arrange them in each packing box 21. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com