Auxiliary device for performing manual work

An auxiliary device and working technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problem of falling and trapping, and achieve the effect of easy manipulation, simple structure and good connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

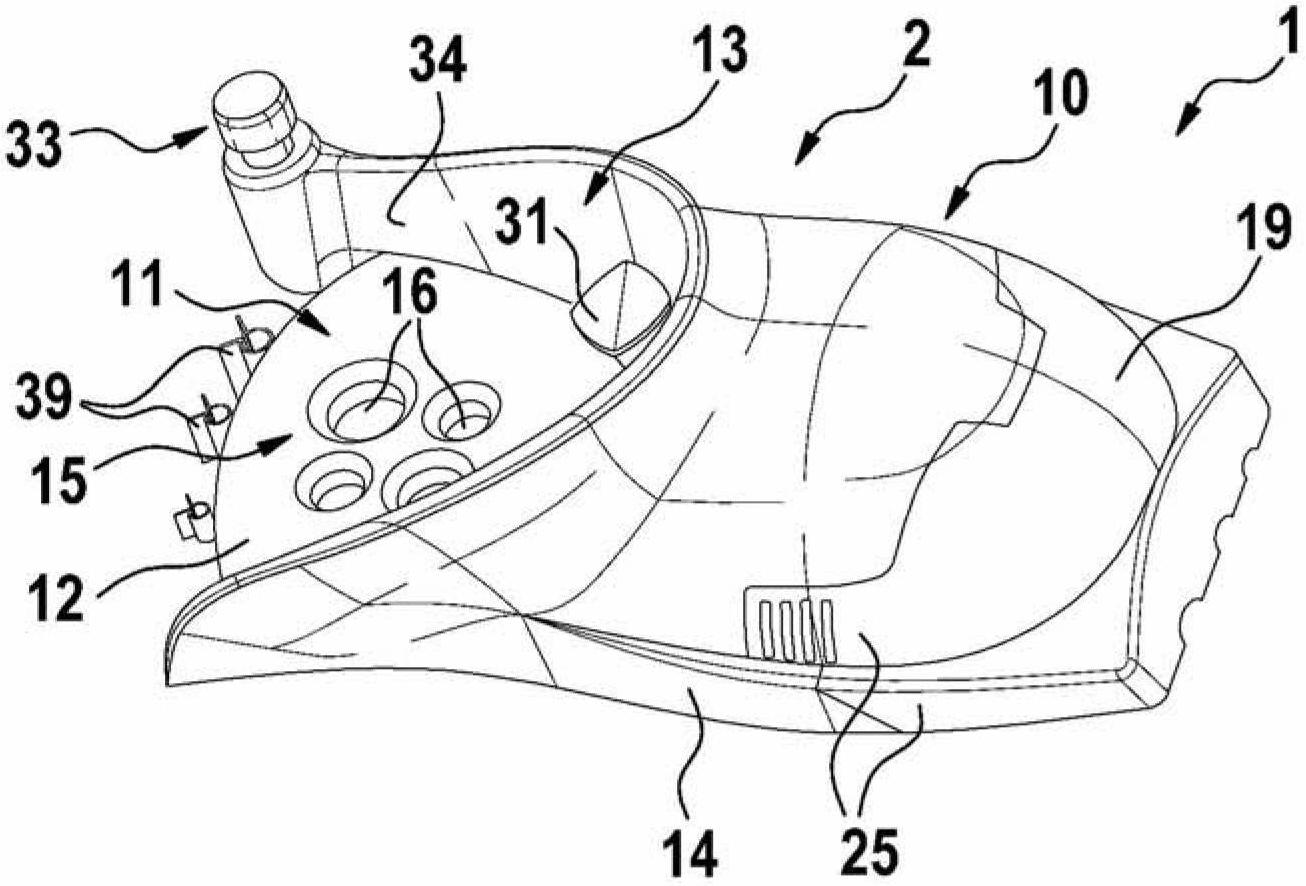

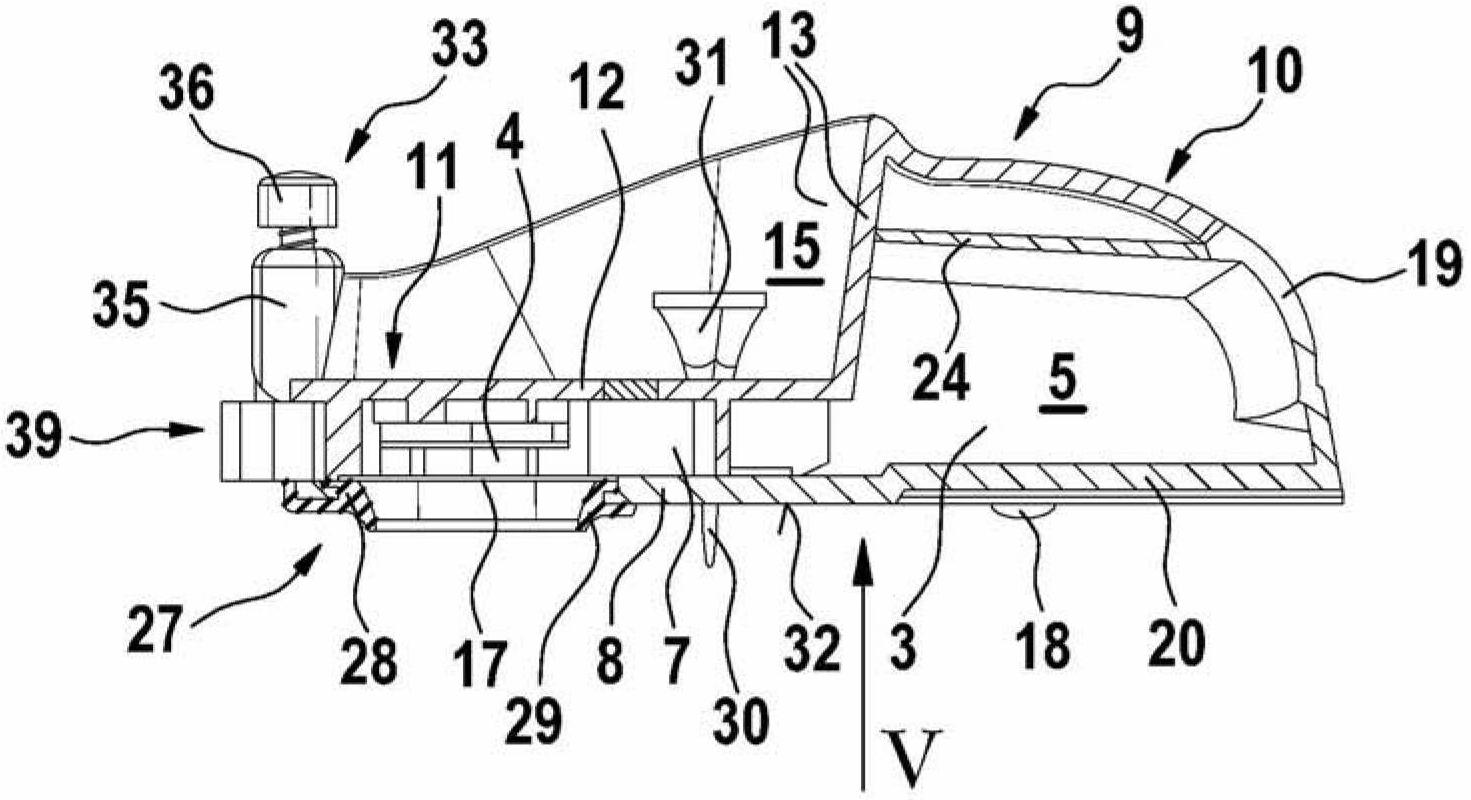

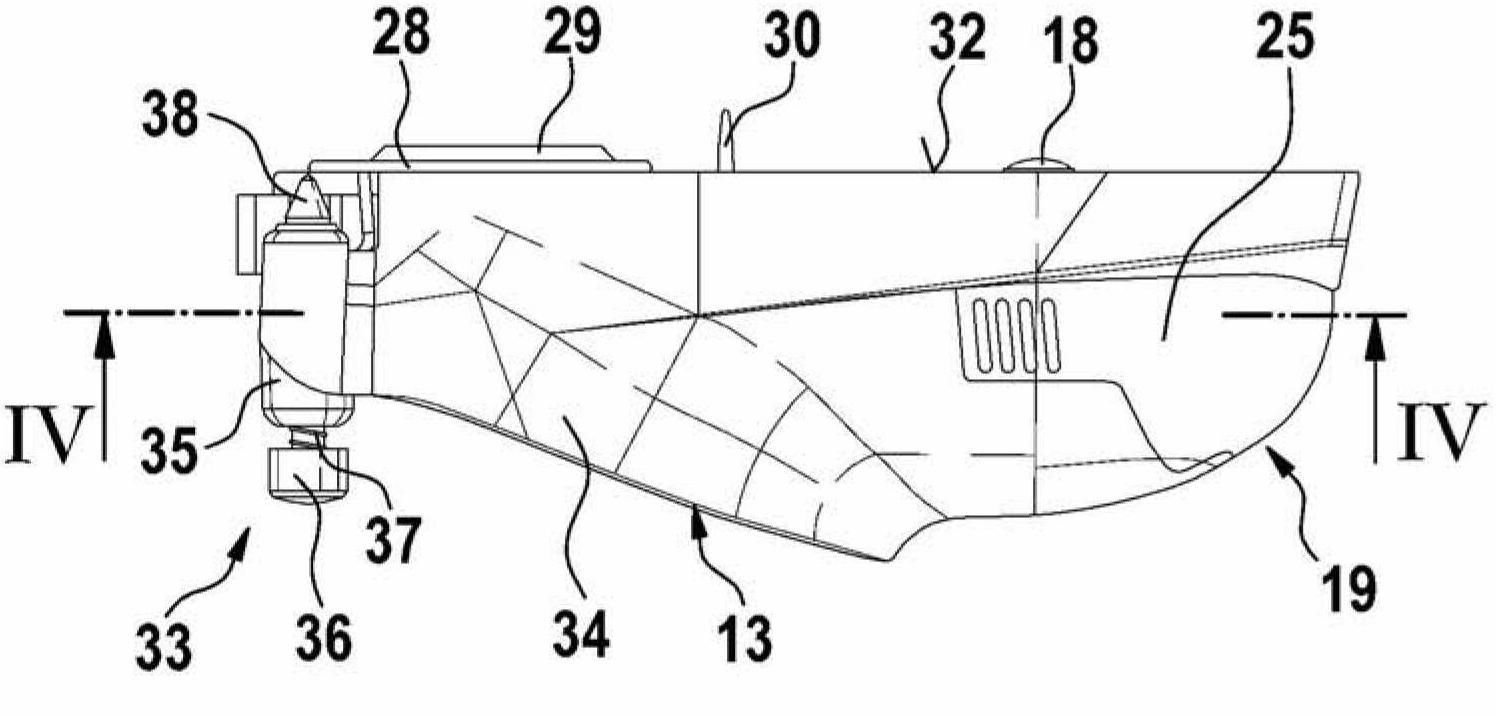

[0025] exist Figures 1 to 8 shows an auxiliary device 1 for performing manual work, which in its basic function forms a cuttings collection box 2 and in this respect encloses a collection chamber 3 with a working application not shown There is a catch chamber 4 through which the drilled tool emerges, and a collection container 5 which sinks relative to the catch chamber 4 and is connected to the catch chamber.

[0026] With respect to the collection box 2, which is elongated in its shape and shaped approximately like a mouse so that it can be handled easily, the capture chamber 4 and the collection container 5 lie opposite each other in the direction of the longitudinal axis 6 of the cuttings collection box 2, exactly Said to be connected via a short channel-like intermediate piece 7 . The collection container 5 is designed like a drawer and is inserted from behind in the direction of the longitudinal axis 6 into the collection box 2 , which has a housing 9 covering its bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com