Chilli sauce and preparation method thereof

A technology for chili sauce and red pepper, applied in the directions of food preparation, application, food science, etc., can solve the problems of ginger and garlic not being placed or even placed, poor flavor, etc., and achieve the effects of increasing flavor quality, rich nutritional value and soft spicy taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Crush 8 parts by mass of red pepper into 1 cm; crush 0.8 parts by mass of fried peanuts into 1 cm; fry 0.2 parts by mass of sesame seeds; beat 1 part by mass of ginger and 1.5 parts by mass of garlic into juice for later use.

[0026] 2) Heat 0.8 parts by mass of sesame oil to 50~60°C, add 0.8 parts by mass of diced pork meat with a size of 1 cm, stir for 2 minutes, add 1.5 parts by mass of bean paste and continue stirring for 2 minutes, add 200ml of water, and boil.

[0027] 3) Add 8 parts by mass of red pepper, heat it to a boil, turn it on and turn off the heat. At this time, 0.8 parts by mass of salt, 0.4 parts by mass of white sugar, 0.8 parts by mass of peanuts, and 0.2 parts by mass of sesame seeds were put into the mixture and stirred evenly. After cooling thoroughly, ginger, garlic and 0.2 parts by mass of monosodium glutamate were added and stirred evenly before bottling.

[0028] 4) The bottles used for hot sauce must be sterilized in advance.

Embodiment 2

[0030] 1) Crush 4 parts by mass of red pepper into 1 cm; crush 0.4 part by mass of fried peanuts into 1 cm; fry 0.1 part by mass of sesame; beat 0.5 part by mass of ginger and 0.5 part by mass of garlic into juice for later use.

[0031] 2) Preheat 0.4 parts by mass of sesame oil to 50-60°C, add 0.4 parts by mass of diced pork meat with a size of 1 cm, stir for 2 minutes, add 0.75 parts by mass of bean paste and continue stirring for 2 minutes, add 200ml of water, and boil.

[0032] 3) Add 4 parts by mass of red pepper and heat it together and turn it on and turn off the heat. At this time, put 0.4 parts by mass of salt, 0.2 parts by mass of white sugar, 0.4 parts by mass of peanuts, and 0.1 parts by mass of sesame seeds together and stir evenly. After cooling thoroughly, add ginger, garlic, and 0.1 parts by mass of monosodium glutamate and stir evenly before bottling.

[0033] 4) The bottles used for hot sauce must be sterilized in advance.

Embodiment 3

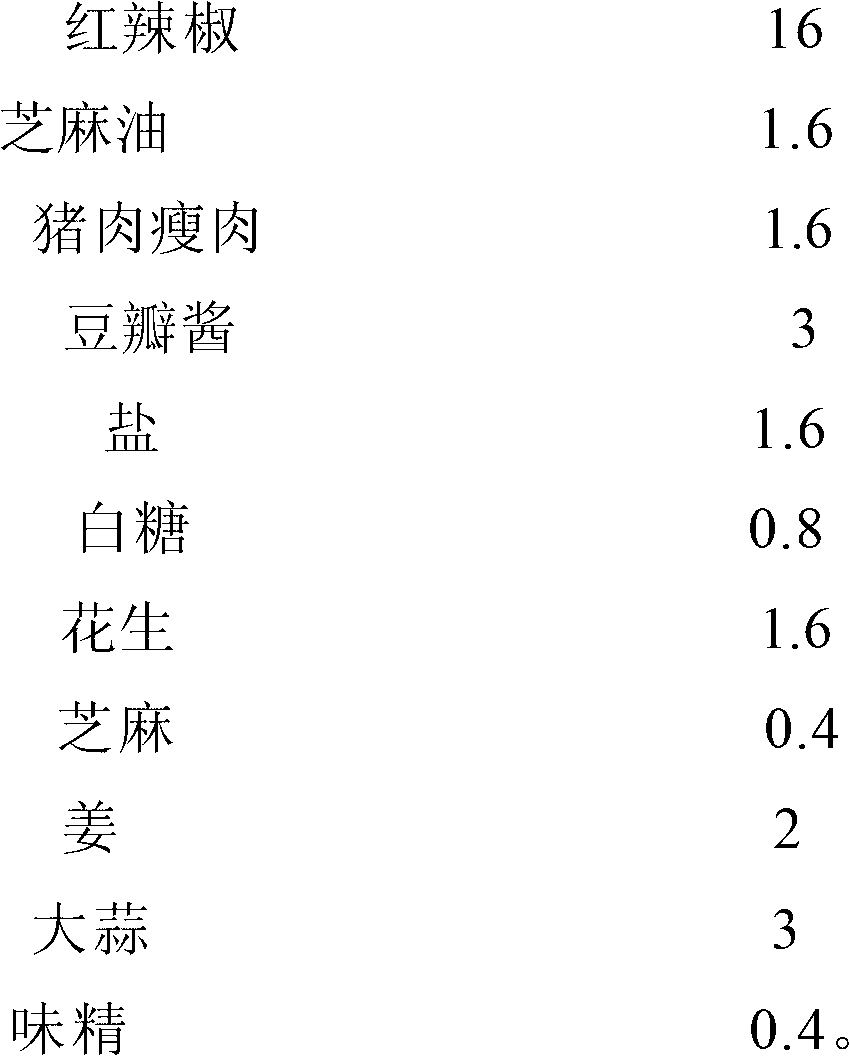

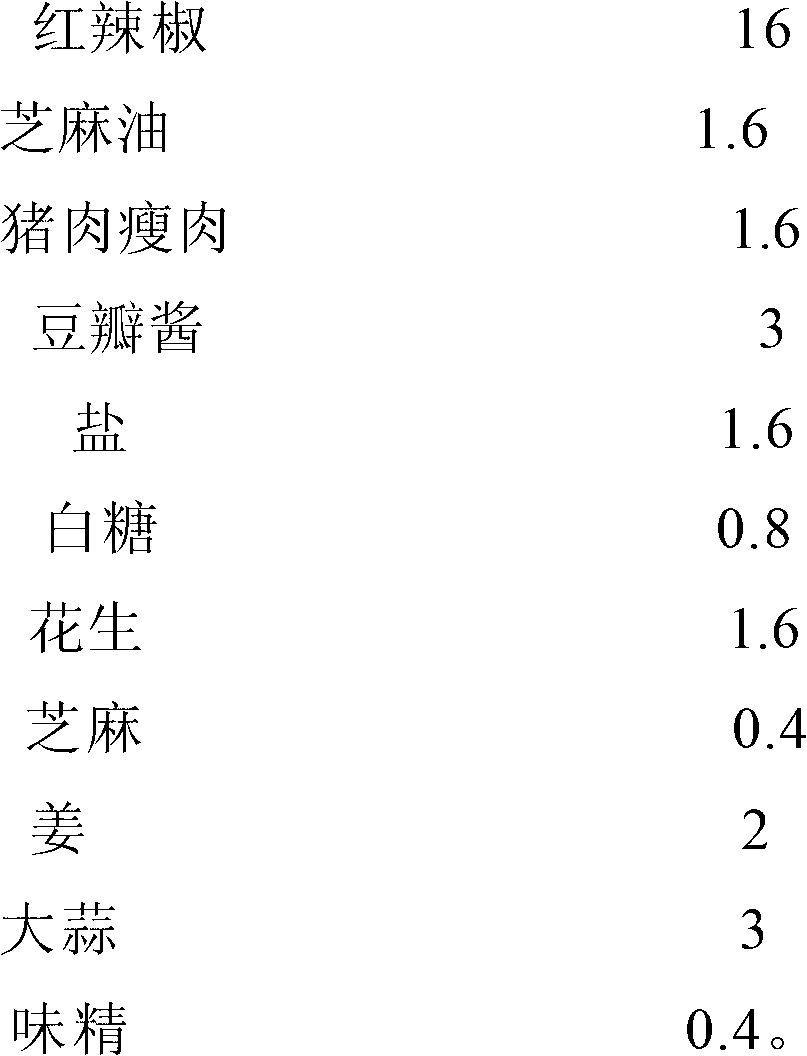

[0035] 1) Crush 16 parts by mass of red pepper into 1 cm; crush 1.6 parts by mass of fried peanuts into 1 cm; fry 0.4 parts by mass of sesame; beat 2 parts by mass of ginger and 3 parts by mass of garlic into juice for later use.

[0036] 2) Preheat 1.6 parts by mass of sesame oil to 50-60°C, add 1.6 parts by mass of diced pork meat with a size of 1 cm, stir for 2 minutes, add 3 parts by mass of bean paste and continue stirring for 2 minutes, add 200ml of water, and boil.

[0037] 3) Add 16 parts by mass of red pepper and heat it to a boil, turn it on and turn off the heat. At this time, 1.6 parts by mass of salt, 0.8 parts by mass of white sugar, 1.6 parts by mass of peanuts, and 0.4 parts by mass of sesame seeds were put into the mixture and stirred evenly. After cooling thoroughly, ginger, garlic and 0.4 parts by mass of monosodium glutamate were added and stirred evenly before bottling.

[0038] 4) The bottles used for hot sauce must be sterilized in advance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com