Spray gun control mechanism and spraying device

A technology of control mechanism and spraying device, which is applied in the direction of building structure, construction, etc., can solve the problems of inconvenient spraying work, inability to adjust the upper and lower angles of the spray gun, and difficulty in spraying, and achieve the effect of eliminating dead ends in spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

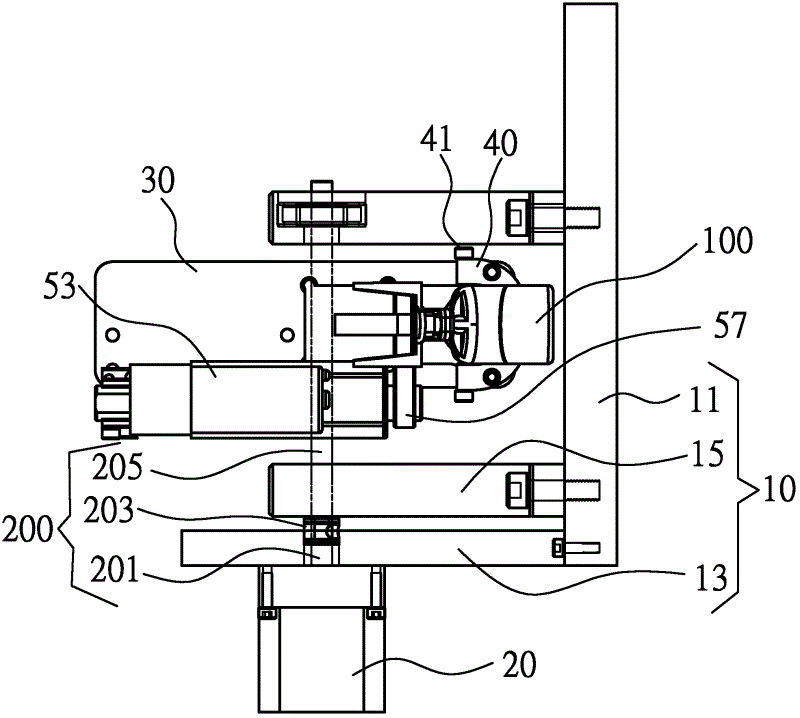

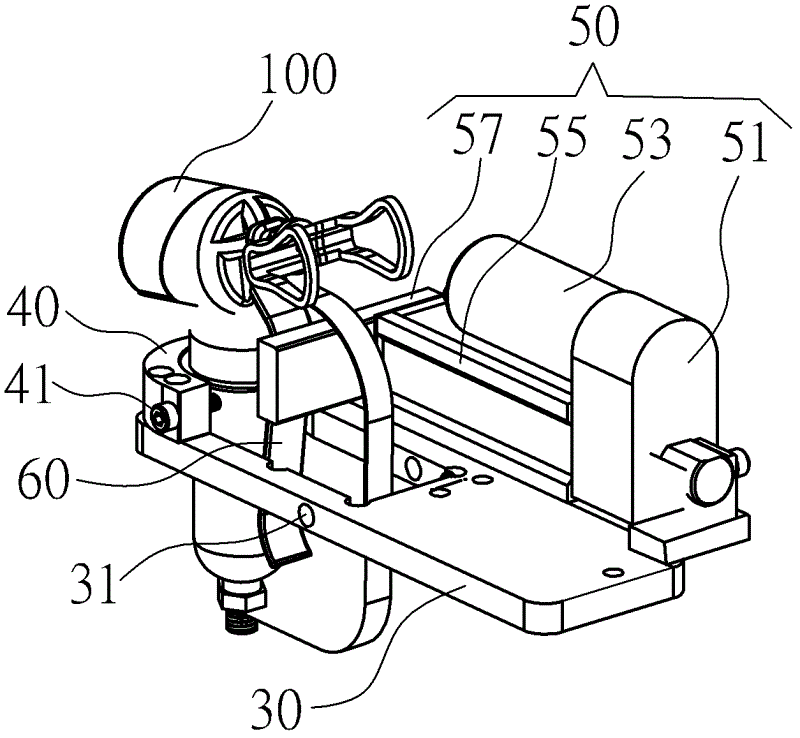

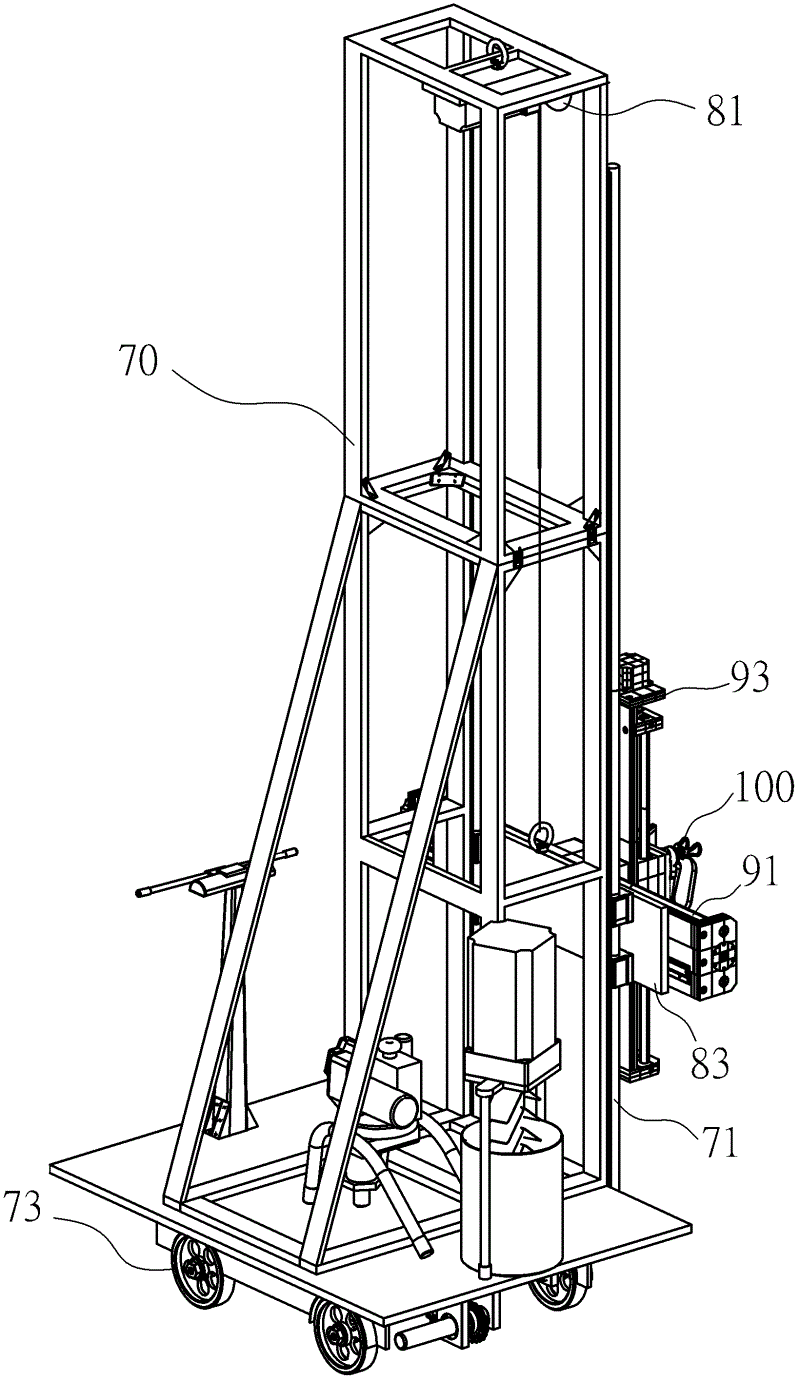

[0011] Please refer to Figure 1~Figure 4 , the embodiment of the present invention provides a spray gun control mechanism and a spraying device provided with the control mechanism, the spray gun control mechanism is used to flexibly adjust the upper and lower angles of the spray gun to eliminate the dead angle of spraying at the upper and lower positions; the spraying device is used for Lift the spray gun control mechanism to a predetermined height and then move in two-dimensional direction for spraying.

[0012] The spray gun control mechanism includes a rotation control assembly for controlling the rotation to adjust the vertical angle of spraying, and a switch control assembly installed on the rotation control assembly for controlling the spray gun 100 to spray.

[0013] The rotation control assembly includes a fixed base 10 and a motor 20 fixed at one end of the fixed base 10, and the motor 20 is a stepping motor or a servo motor. The motor 20 is provided with an output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com