On-site load simulation experiment detection device and detection method for large continuous beam structure

A detection device, load simulation technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., to prevent lateral instability, the equipment structure is simple, and meet the requirements of design and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

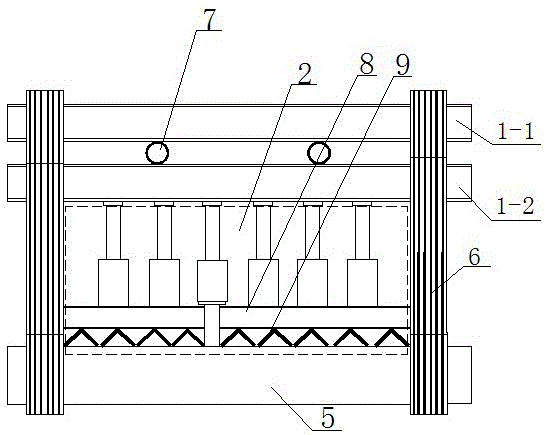

[0026] Such as figure 1 A large-scale continuous beam structure field load simulation test detection device shown includes a structural beam 1 arranged on the top of the detection engineering beam 5, and the structural beam 1 is stacked by an upper steel beam 1-1 and a lower steel beam 1-2 Composition, there are also two spacers 7 between the two steel beams, the distance between the two spacers is not less than half of the length of the steel beams, and a transmission line is set between the steel beams 1-2 below and the detection engineering beam 5. Force and detection device 2, the two ends of the structural beam 1 and the detection engineering beam 5 are all connected by wire rope 6, and a pad beam 8 is also arranged between the jack and the detection engineering beam 5, between the pad beam 8 and the detection engineering beam 5 A corrugated backing plate 9 is provided, that is, the steel wire rope is directly wound on the structural beam and the detection engineering bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com