Method and machine for filling capsules or similar with at least two products, in particular pharmaceutical products in granules

A technology for pharmaceutical products and analogues, applied in capsule delivery, pharmaceutical formulation, drug delivery, etc., can solve problems such as unfavorable weighing and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

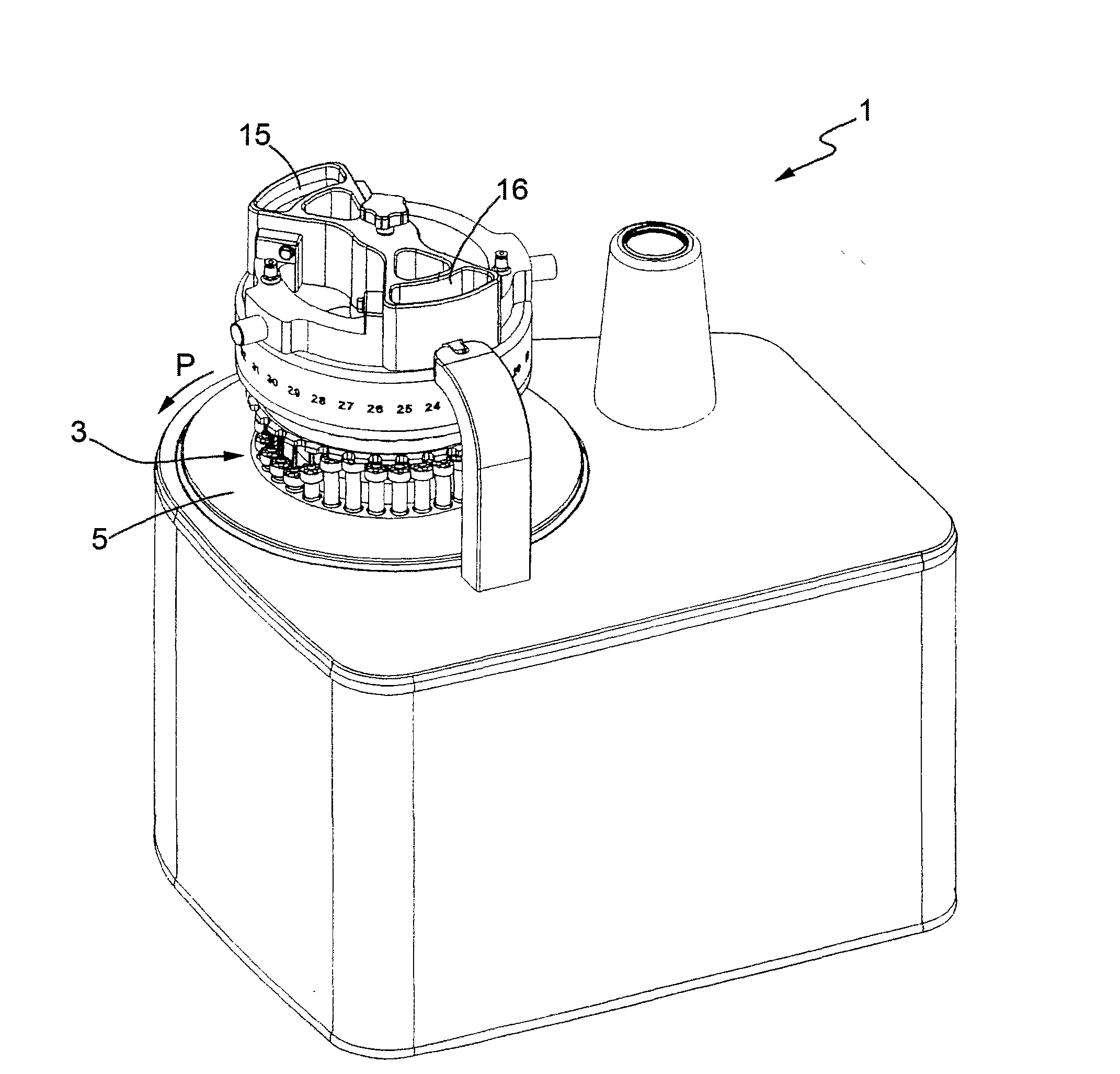

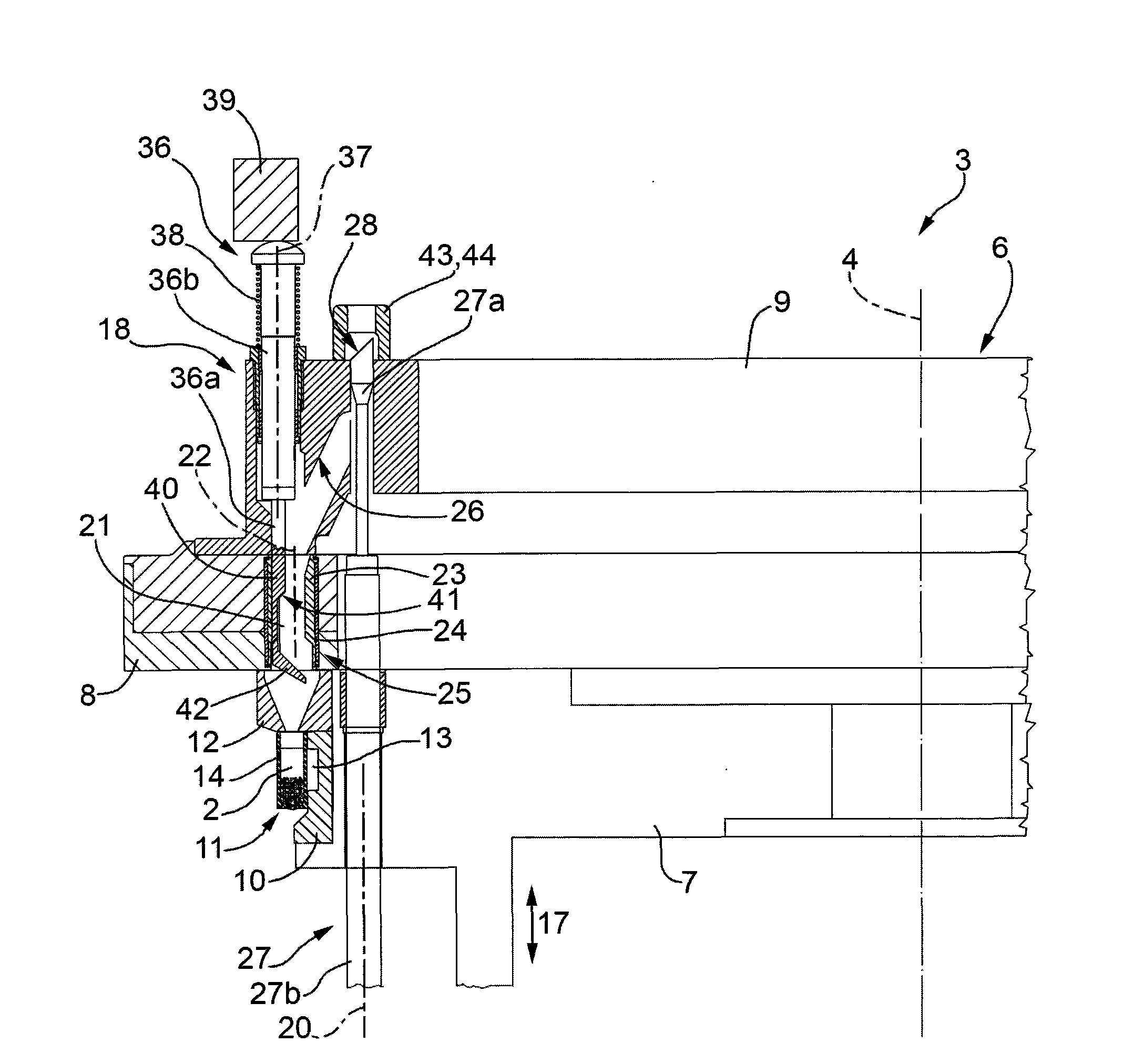

[0030] refer to figure 1 To 3, reference numeral 1 generally designates a machine for filling known capsules (not shown) with at least one granular pharmaceutical product. Each capsule (not shown) comprises a substantially cup-shaped bottom shell 2 and a top shell (not shown) for closing the bottom shell 2 .

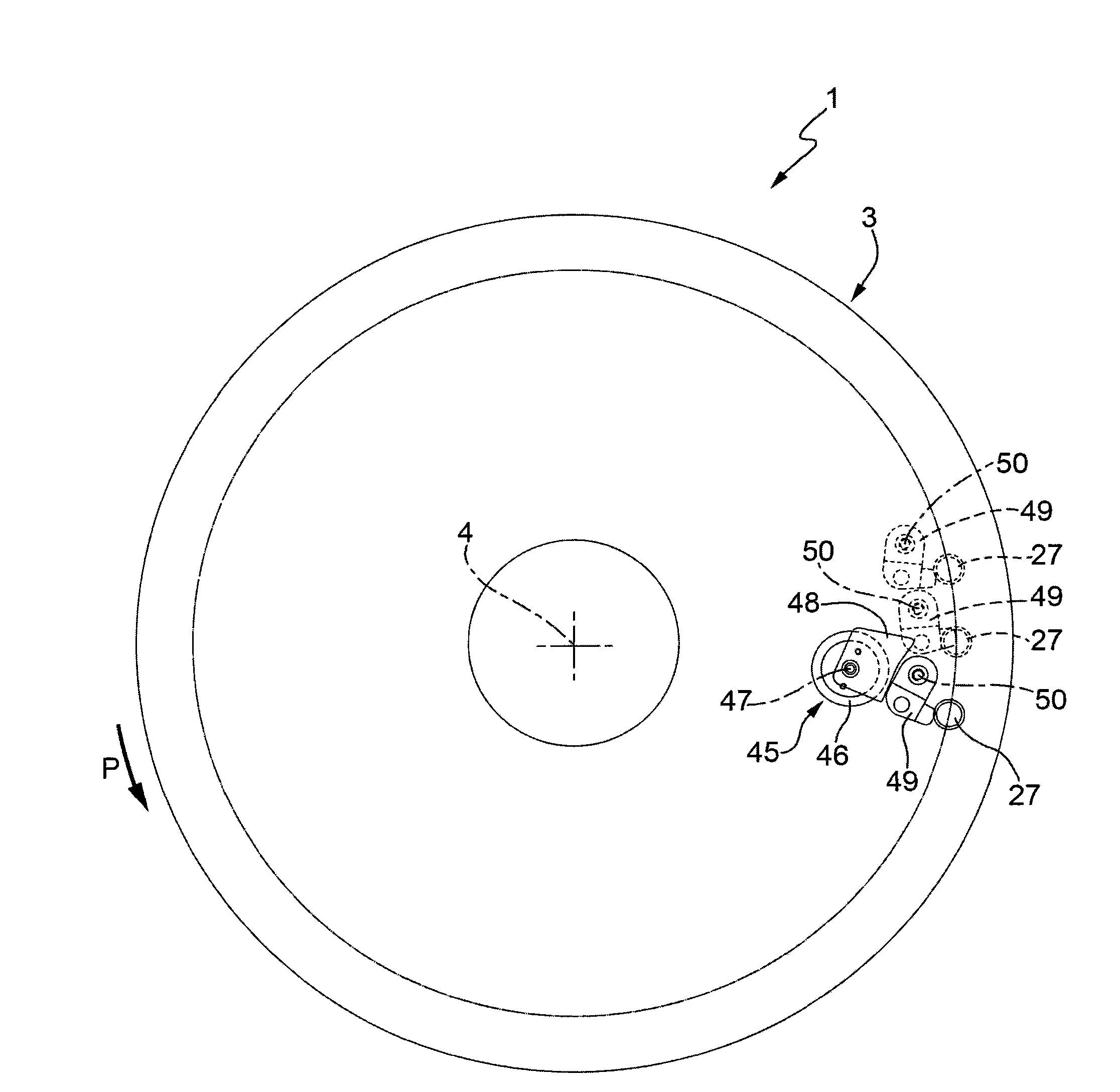

[0031] The machine 1 comprises a metering wheel 3 which in turn includes a support shaft (not shown), the metering wheel 3 having a generally vertical longitudinal axis 4, mounted on a fixed frame 5 of the machine 1, the metering wheel 3 passing through a Known drive means (not shown) rotate continuously about axis 4 relative to frame 5 , and metering wheel 3 supports metering drum 6 .

[0032] The drum 6 comprises a chassis 7, a middle disc 8 and a top disc 9, the chassis 7, the middle disc 8 and the top disc 9 are coaxial with the axis 4 and perpendicular to the axis 4, the chassis 7, the middle disc 8 and the top disc 9 are at an angle to each other is connected in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com