Wind turbine stator winding winding method

A winding method and stator winding technology, applied in the field of winding, can solve the problems of embedding wires and complicated wiring, etc., and achieve the effects of easy winding method, short wire routing distance, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

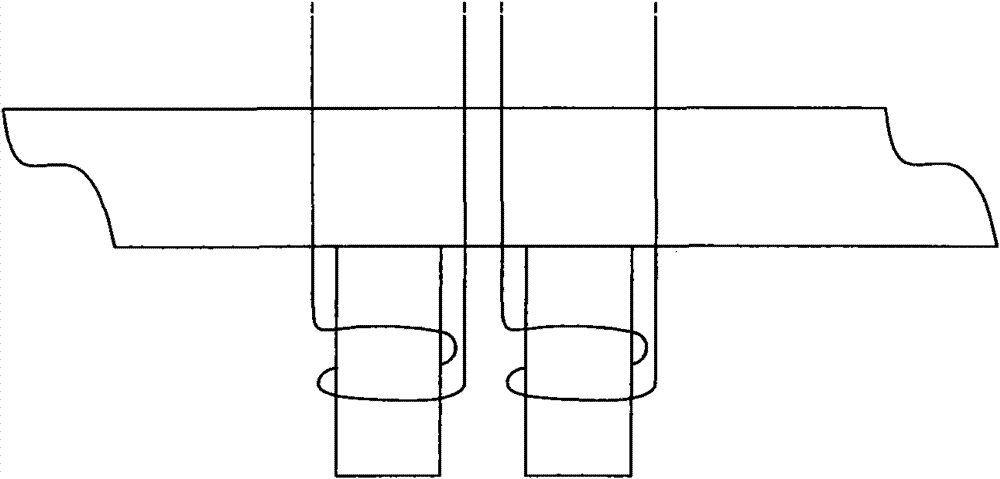

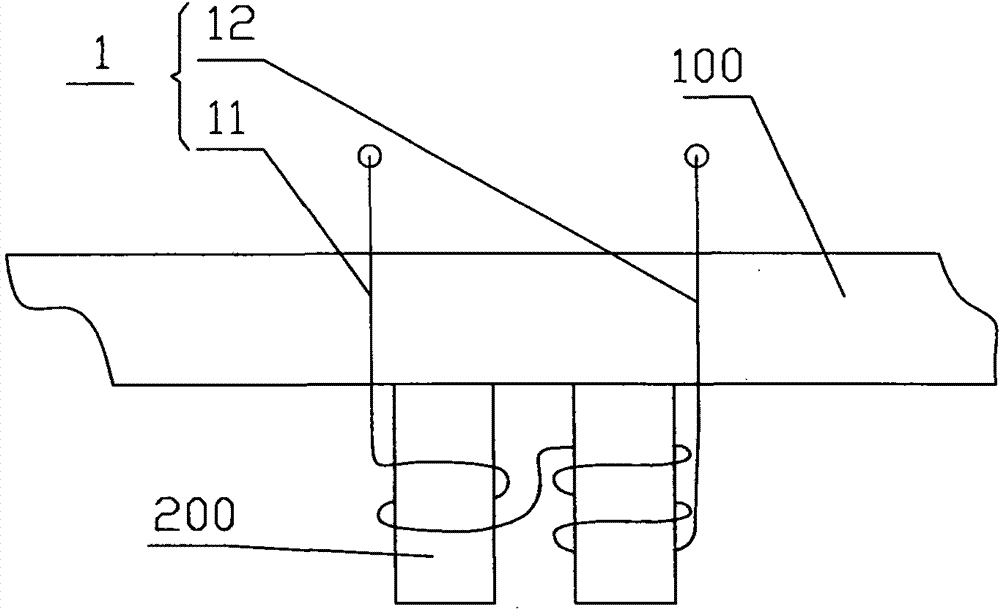

[0017] Embodiment one, figure 2 It is a schematic diagram of the wind generator stator winding of the present invention. In the figure, 100 is the stator core, and 200 is the teeth on the stator core. The stator winding 1 of the present invention includes the first half winding 11 arranged on two adjacent teeth 200 The winding direction is opposite to that of the second half-winding 12 , and the end of the first half-winding 11 is connected to the head end of the second half-winding 12 . When winding, first, the first half winding 11 is wound on the linear bar mold, then the second half winding 11 is reversely wound, and the second half winding 12 is turned over to form a connected, reversely wound When installing the stator winding 1 composed of two half-windings, the two connected half-windings 11 and 12 are inserted into the adjacent stator teeth 200 at one time, thereby reducing the number of coil terminals and embedding wires. The number of times, improve the installati...

Embodiment 2

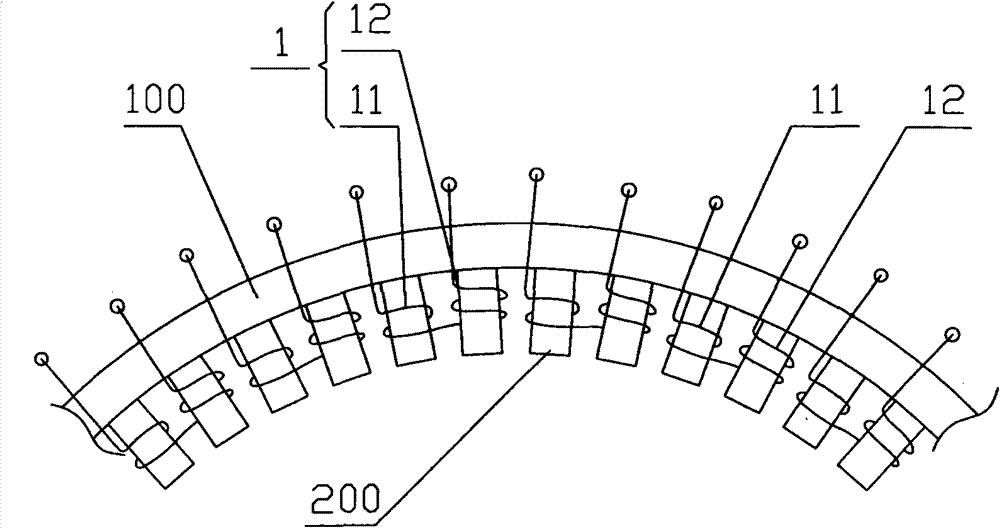

[0018] Embodiment two, see image 3 , the figure shows a quarter of the stator winding of the wind generator of the present invention, the stator core 100 has 48 teeth 200 (12 teeth are shown in the figure), and the stator core 100 is provided with 24 windings 1 ( 6 windings 1) are shown in the figure, and each winding 1 includes two one-time windings formed on two adjacent teeth 200 and connected as a whole, two half-windings: the first half-winding 11 and the The second half-winding 12 has the same winding direction, and the end of the first winding 11 is connected to the end of the second winding 12 . When winding, see Figure 4 , the figure shows the winding method of this embodiment, 300 in the figure is a linear rod mold, its two ends have the same shape and diameter, and there is a transition section 301 in the middle, first the first winding 11 is placed on the linear rod mold Winding is carried out at one end, and after completion, the wire is crossed over the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com