Hole eye tangent vibration type seed feeding method and device

A technology of tangential vibration and seeding device, which is applied in the direction of spaced quantitative sowing machinery, seeder parts, etc., can solve the problems of non-continuous sowing, frequent shearing of seeding belts, and difficulty in generating force fields, etc., to achieve improved The effect of clearing seeds, increasing crop yield, and increasing seed filling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

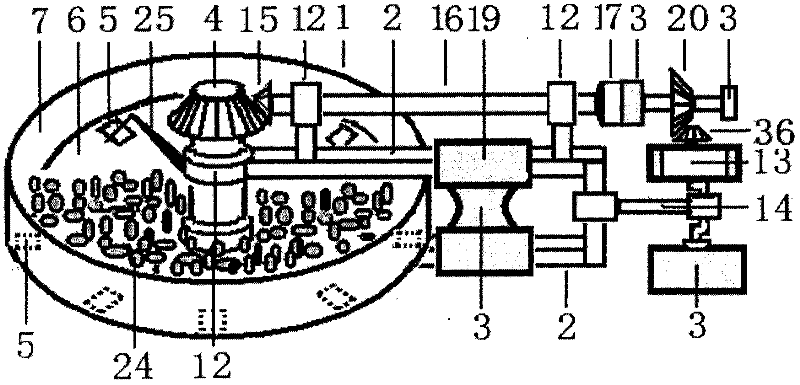

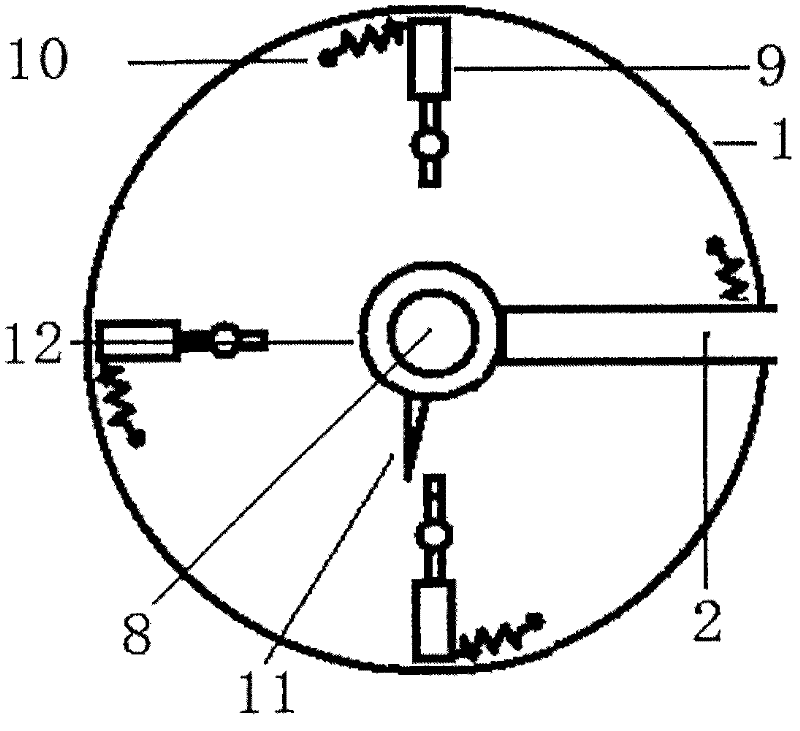

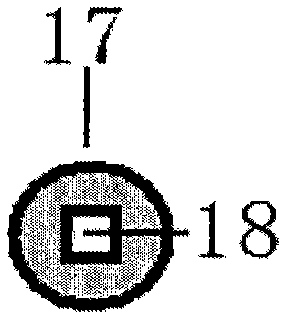

[0022] Method 1: A socket tangential vibrating seed metering device is characterized in that it is composed of a seed metering box (1), a vibrating frame (2), a frame (3) and a driving device; the seed metering box (1) is The front is high and the rear is low, the bottom is a garden-shaped bottom plate (6), the edge has a seed protection side weir (7), the center is fixedly connected to the bearing (8) perpendicular to the bottom plate, and the lower end of the shaft (8) passes through the bottom plate and is hinged on the bearing (12), the top is fixedly connected to the umbrella wheel one (4), and at least one week of seeding holes (5) are evenly arranged on the bottom plate circumference. There are seed clearing needles (25) above the seed metering holes. The clearing needles are elastic and the tip is tight Pressed on the surface of the seeding hole, the tail end is fixed on the vibrating frame (2); there is a seeding door (9) under the seeding hole, the seeding door is hin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com