Assembly structure for rack and rubber roll as well as thermal printer applying assembly structure

A technology for thermal printers and assembly structures, applied in printing devices, printing, etc., can solve the problems of affecting the normal operation of rubber rollers, large bearing movement, and increasing manufacturing costs, so as to ensure normal and stable operation, low cost, and zero cost. The effect of easy access to parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

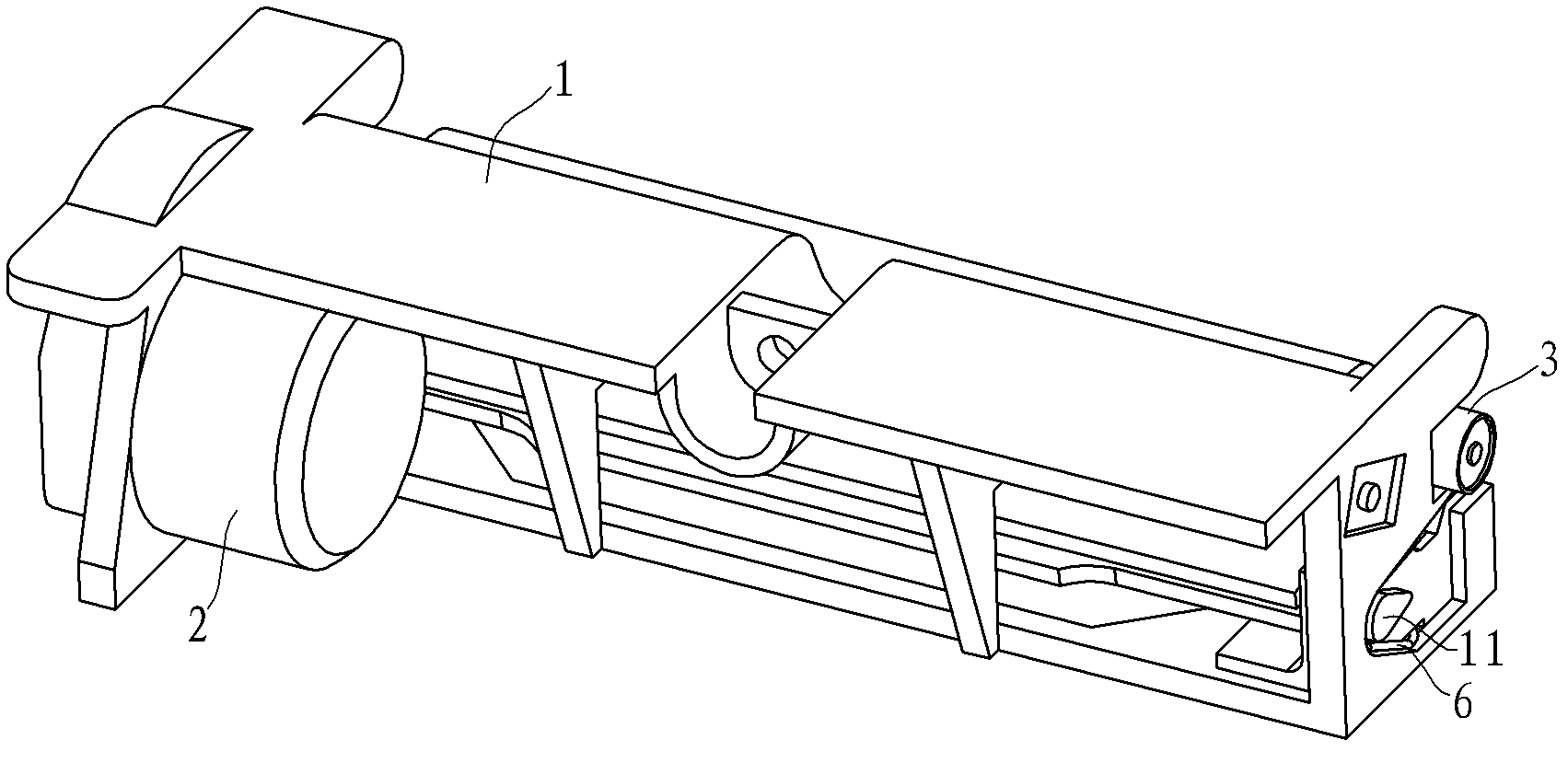

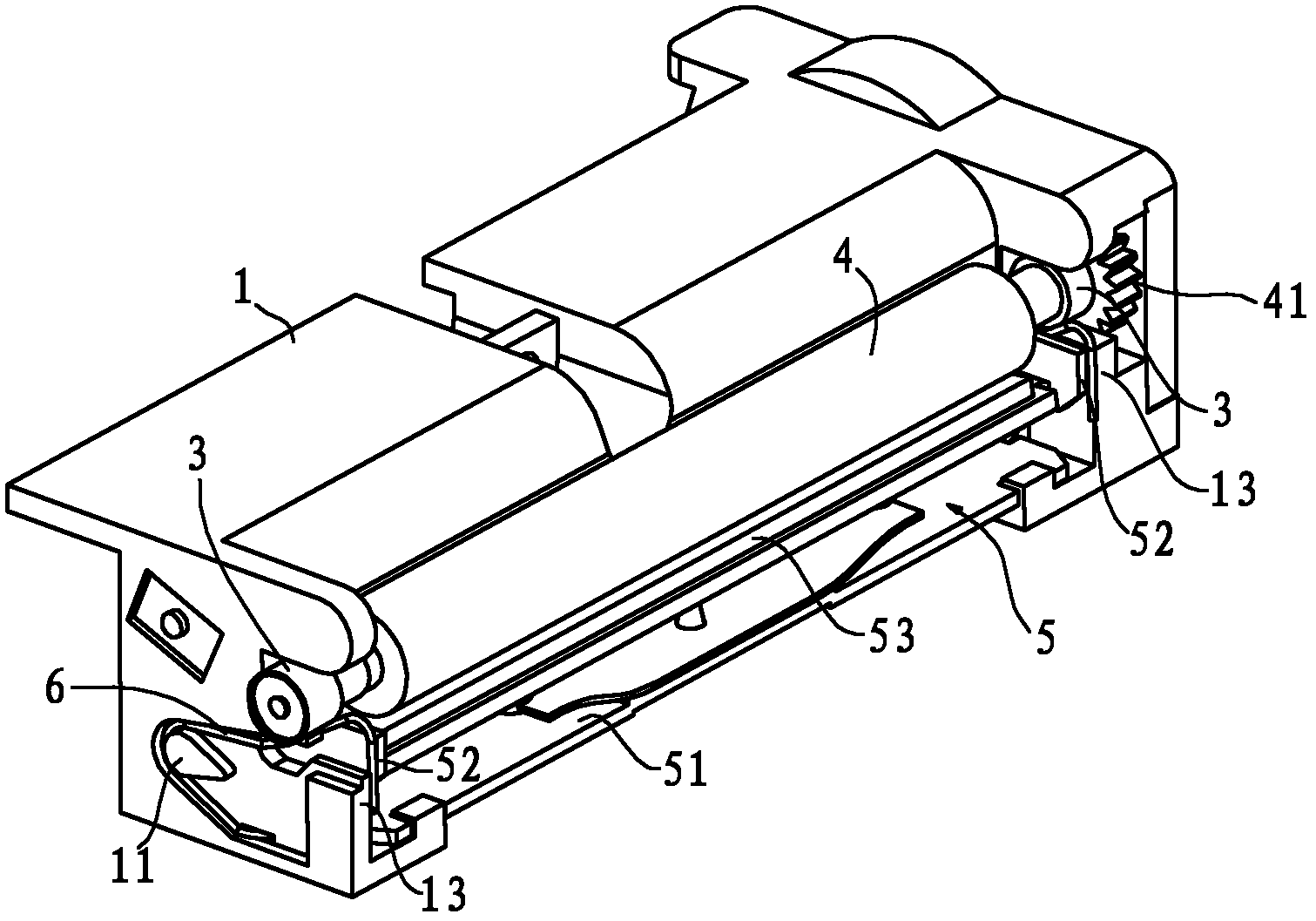

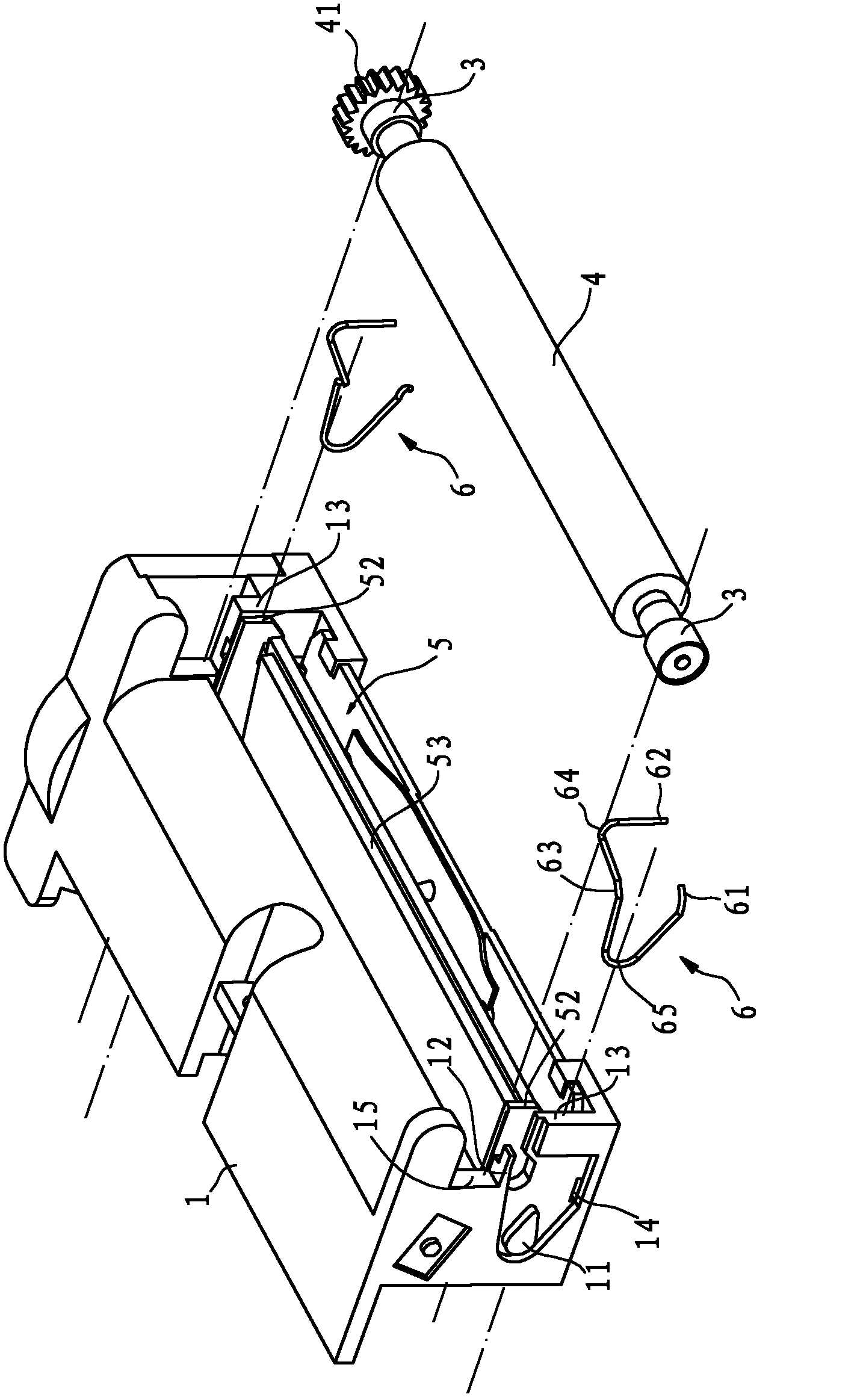

[0023] Such as figure 1 , figure 2 and image 3 As shown, the thermal printer in this embodiment includes a main frame 1 and a motor 2 arranged on the main frame 1, a transmission gear assembly (not shown in the figure), a print head assembly 5 and a rubber roller 4, and the power of the transmission gear assembly The input end meshes with the active output gear of the motor 1, and the power output end meshes with the rubber roller gear 41 located at the end of the rubber roller 4. The main frame 1 has a central area, and side walls 13 are formed on both sides of the central area. The printer head assembly 5 includes a bracket 51 disposed in the central area and a print head 53 disposed on the bracket 51 , and side portions 52 are formed on both sides of the bracket 51 .

[0024] There are two bearings 3 at both ends of the rubber roller 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com