Pile cutting construction method of bored concrete pile

A construction method and technology of cast-in-situ piles, which are applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of large number of drilling holes and silent breakers, low construction efficiency, and high construction cost, so as to save engineering cost and environment Less pollution and less impact on the environment

Active Publication Date: 2012-04-25

ZHEJIANG UNIV CITY COLLEGE +1

View PDF7 Cites 43 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In China, after drilling with a hand-held pneumatic drill, the pile head is broken into blocks by embedding a silent breaker. However, the hole diameter of reinforced concrete needs to be 40-50mm and the hole dista

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

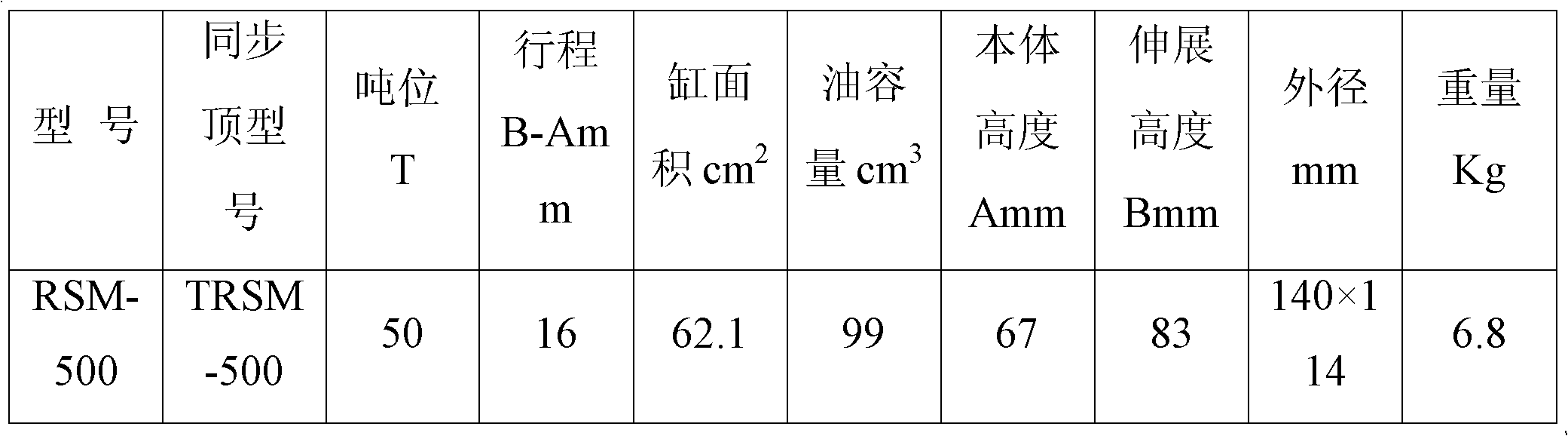

The invention provides a pile cutting construction method of a bored concrete pile, comprising the following steps of: sleeving a protective barrel with grooves on a pore top prior to filling pile body concrete to the bored concrete pile; placing a steel reinforcement cage after arranging an isolation casing on a vertical main rib of the steel reinforcement cage on the pile top of the bored concrete pile; filling concrete into the bored concrete pile to obtain the pile; implanting a lifting ring on an over-filled top; after meeting a concrete curing demand, disassembling the protective barrel with the grooves; when the pile body reaches a design strength standard value by 70%, drilling pores at parts on the pile body, corresponding to the grooves of the protective barrel, to form filling pores above a pile top design standard; filling a soundless cracking agent into the pores, wherein the soundless cracking agent functions as expansion to cut down the over-filled pile top in combination with a thinned synchronous jack placed in the grooves. Compared with the traditional methods such as pile cutting with the soundless cracking agent, manual chiseling and pile cracking by hydraulic crushing and the like, the pile cutting construction method disclosed by the invention has the advantages of fast construction speed, low manufacture cost, small influence to the environment and better technical and economic benefits.

Description

technical field [0001] The invention relates to a method for cutting off the super-filled portion of a cast-in-situ pile higher than the design elevation of the pile top, in particular to a method for cutting piles in combination with a soundless breaking agent and a synchronous thin jack. Background technique [0002] "Code for Construction Quality Acceptance of Building Foundation Engineering" (GB50208-2002) stipulates that the pile top elevation of cast-in-place piles should be at least 0.5m higher than the design elevation; The concrete superfill height of cast-in-situ piles has also been specified. The specification stipulates that the amount of pouring of pile foundation concrete is large at one time, or the foundation pile of concrete poured underwater, because the air bubbles or pores inside the concrete rise to the top of the pile during the vibration process, the pile top will be laitance within a certain range. 1. Mud or mortar mixture during underwater concrete ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E02D5/38E02D9/00

Inventor 王新泉陈永辉陈龙陈庚

Owner ZHEJIANG UNIV CITY COLLEGE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com