New technology for electrified fastening drainage wire clamp

A drainage clamp and new technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of high labor intensity, long operation time, and complicated operation process, so as to improve labor efficiency, reduce labor intensity, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

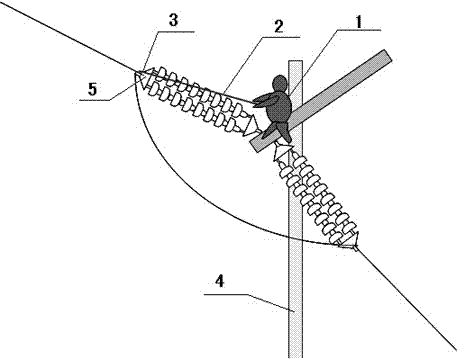

[0016] combined with Figure 1-2 , to further describe the present invention:

[0017] The new process of live fastening and drainage wire clamp of the present invention is realized by the following operation steps:

[0018] (a) Do a good job of ground preparation for live working tools;

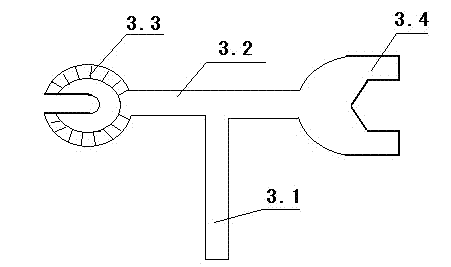

[0019] (b) The ground potential operator 1 carries the transfer rope to the pole 4, and the ground operator fixes the live operation wrench 3 with the adjusted opening size on the insulating operating rod 2 and passes it to the ground potential operator;

[0020] (c) The ground worker 1 uses the monitoring device to direct the ground potential operator to use the insulating operating rod 2 to clamp the live operation wrench 3 on the loose nut of the drain clamp, and the ground potential worker 1 uses the insulating operating rod 2 to fasten the drain clamp Bolt 5;

[0021] (d) The ground potential staff cooperates with the ground staff to transfer the insulating operating rod 2 to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com