Railway vehicle driver operating console on-vehicle integrated assembly process

A railway vehicle and assembly process technology, applied to locomotives, etc., can solve problems such as difficult maintenance and repair, driver fatigue, low assembly precision, etc., and achieve the effect of simple and smooth lines, high degree of modularization, and high assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

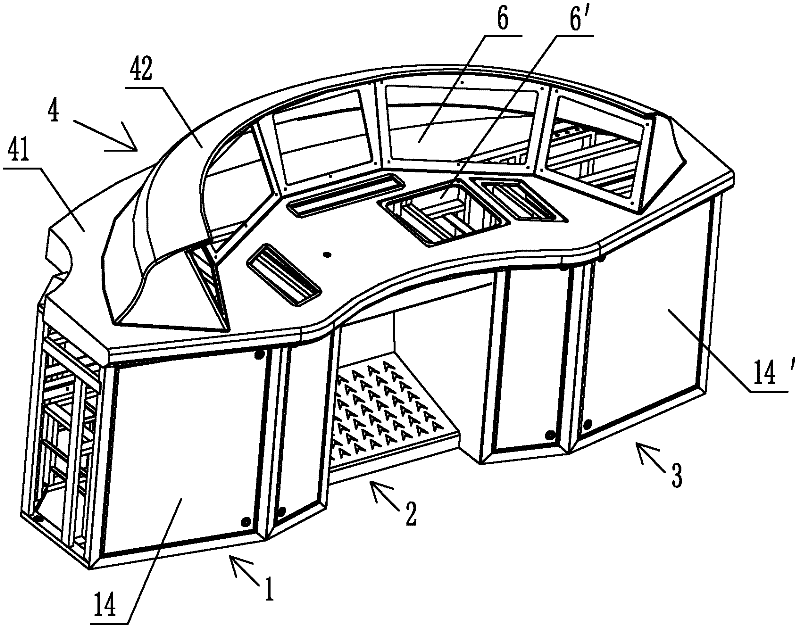

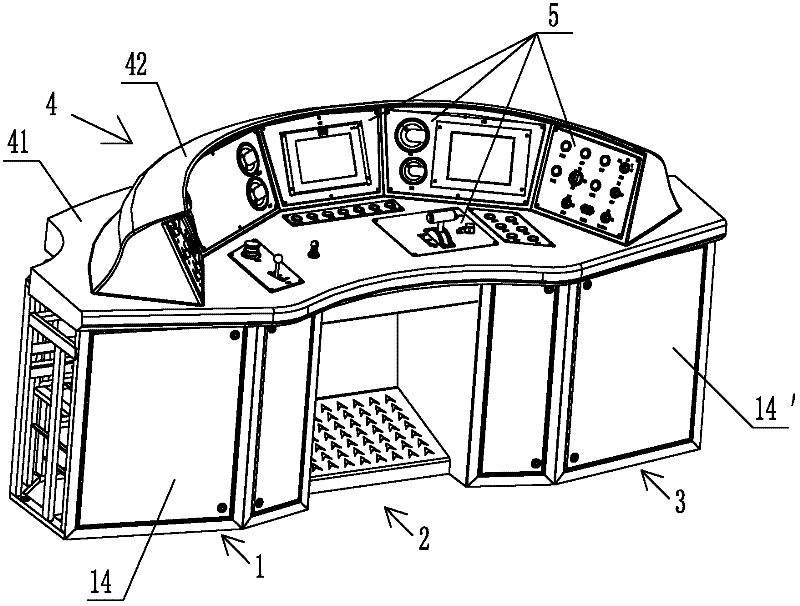

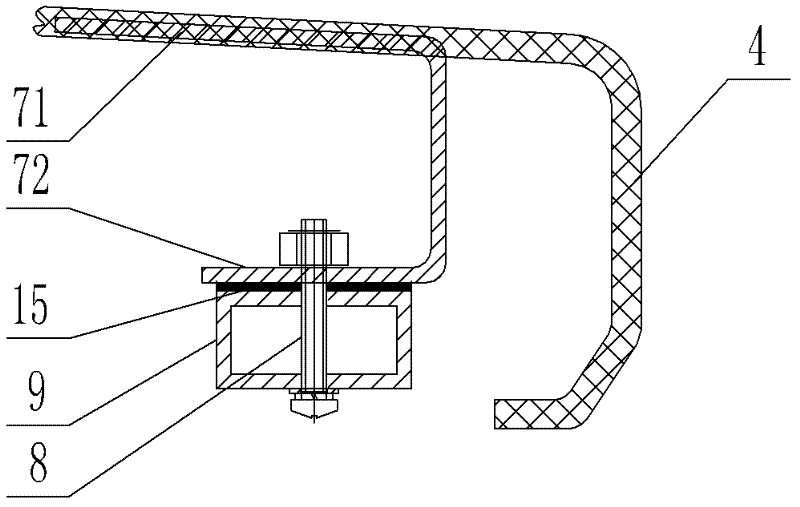

[0022] The railway vehicle driver's console to be assembled in this embodiment, such as figure 1 , figure 2 As shown, it has a cabinet body composed of left cabinet body 1, middle cabinet body 2, and right cabinet body 3. The windows 6, 6' for installing the component panel 5 are left, and the component panel 5 embedded with the operating device or display device is installed at the window 6, 6' of the table composition 4; image 3 As shown, the lower surface of the edge of the table top composition 4 is embedded with a connecting angle iron 7, and the connecting angle iron 7 is fixedly connected with the profile 9 formed by the cabinet body through bolts 8; Figure 4 As shown, the countertop composition 4 is lined with steel plate 10, and the window 6 of the countertop composition 4 is provided with component panel installation holes 11, and nuts 12 are embedded in the corresponding positions on the back, and the component panel 5 is fixed on the countertop composition 4 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com