Multi-link straight line guide independent suspension with 3-RRR telescopic compensation mechanism

A compensation mechanism, independent suspension technology, applied in the direction of suspension, elastic suspension, cantilever mounted on the pivot, etc., can solve the problem of large sliding friction at the moving pair, poor bending rigidity, unsuitable for suspension guide mechanism and other problems, to achieve the effect of convenient assembly and adjustment, reduce wear and tear, and improve handling stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

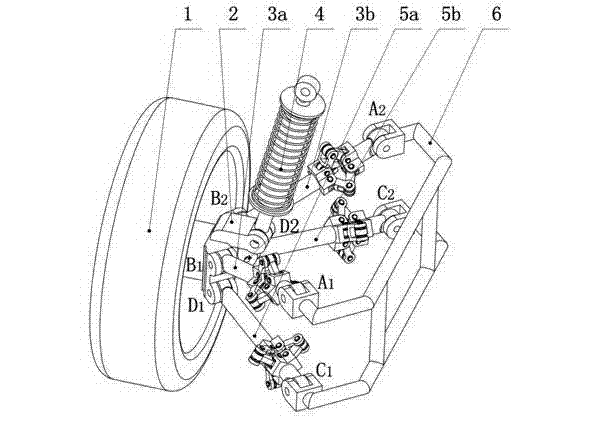

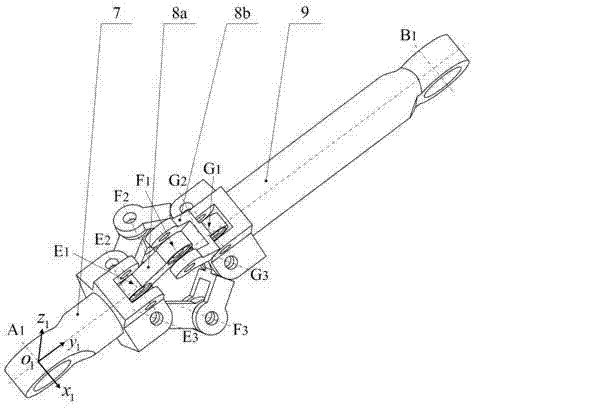

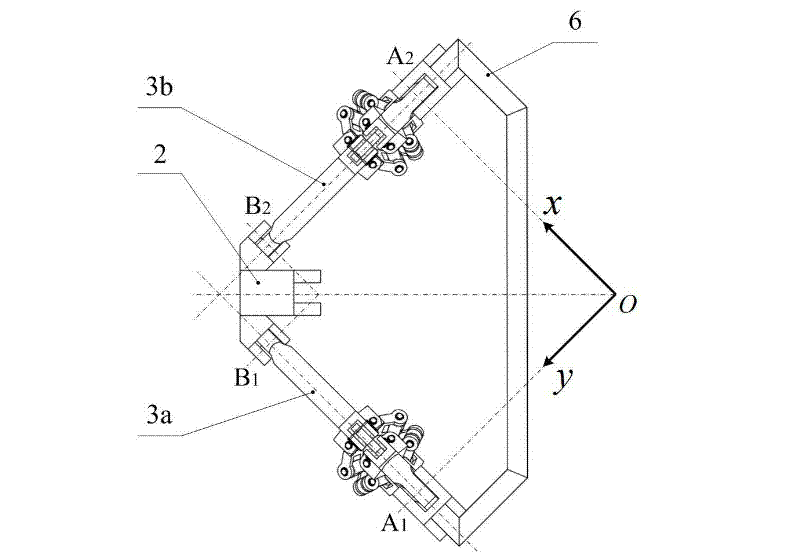

[0028] Embodiment 1: as figure 1 , this kind of multi-link linear guide independent suspension with 3-RRR telescopic compensation mechanism, including wheel 1, body or frame 6, spring damper system 4 and steering knuckle 2, said steering knuckle 2 passes through the hub The unit is connected with the wheel 1, and the spring damper system 4 is respectively connected with the steering knuckle 2 and the vehicle body or frame 6 through the ball joint, and also includes four suspension branch chains, which are respectively the first suspension branch chain 3a on the upper side, The second suspension branch chain 3b on the upper side, the first suspension branch chain 5a on the lower side, and the second suspension branch chain 5b on the lower side; the suspension branch chains all include an inner connecting rod 7 and an outer connecting rod 9 Three identical RRR kinematic chains composed of three rotating pairs, referred to as 3-RRR mechanism, and three identical RRR kinematic cha...

Embodiment 2

[0146] Embodiment 2: The suspension mechanism adds a branch chain on the basis of Embodiment 1, and the vertical plane where the added suspension branch chain is located coincides with or is parallel to the vertical plane where other suspension branch chains are located. , increasing the strength and rigidity of the mechanism, and the rest of the structure is the same as in Example 1.

Embodiment 3

[0147] Embodiment 3: The suspension mechanism adds two branch chains on the basis of embodiment 1, and the vertical plane where the added suspension branch chains are located coincides with the vertical plane intersection lines where other suspension branch chains are located or Parallel increases the strength and rigidity of the mechanism, and the rest of the structure is the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com