Steel ring diameter adjusting mechanism for wire drawing machine

A technology of adjusting mechanism and traveler, applied in metal wire drawing, metal drawing forming tools, metal processing equipment, etc., can solve the problem of large adjusting screw and fine mold adjusting flange, time-wasting adjustment of traveler diameter, and difficult product quality. To meet the requirements and other issues, to achieve the effect of avoiding unstable ring diameter, easy operation and stable ring diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

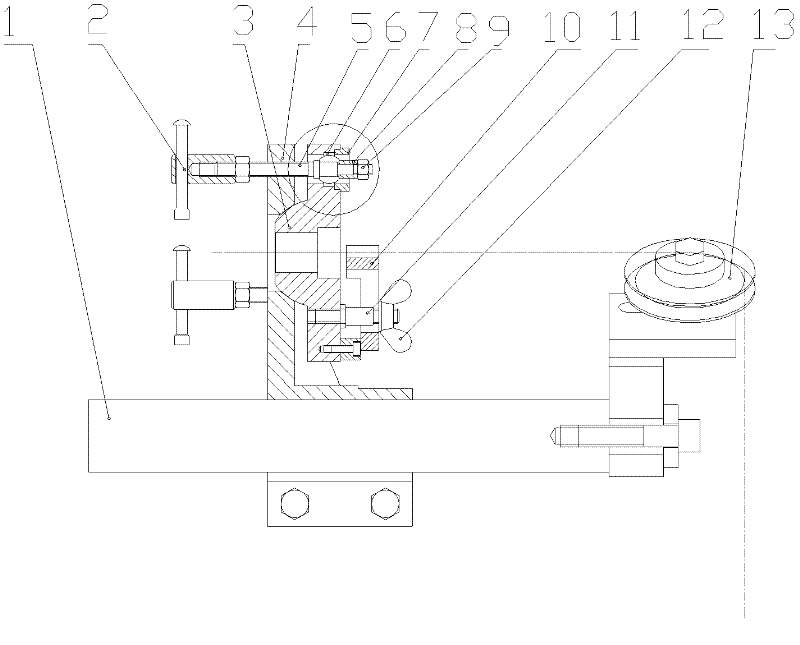

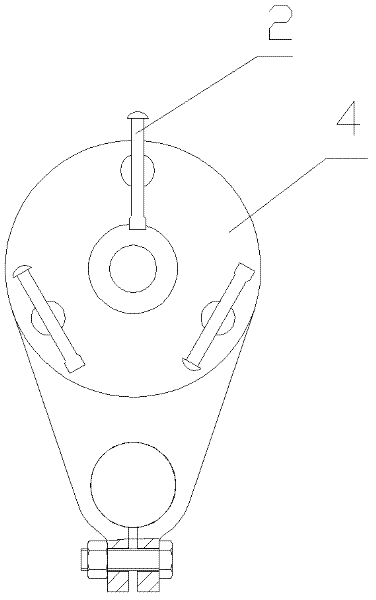

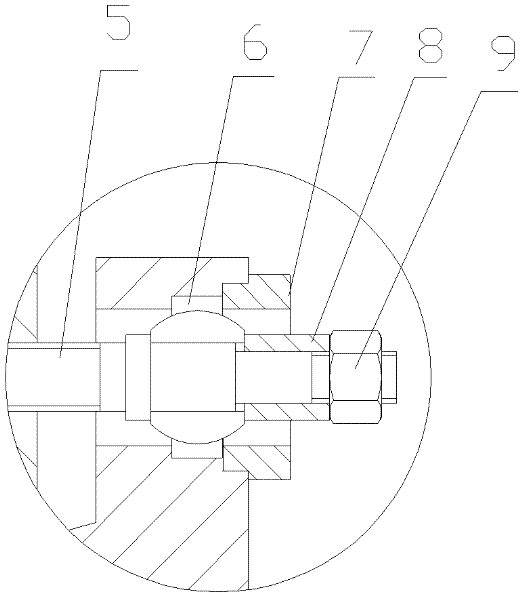

[0018] combine figure 1 , figure 2 and image 3 As shown, the wire ring diameter adjustment mechanism of the wire drawing machine in this embodiment includes a fine mold support 4, a fine mold adjustment flange 3 and three adjustment bolts 5, and the three adjustment bolts 5 are uniformly distributed along the circumference of the fine mold adjustment flange. distribution, one end of the adjusting bolt 5 is provided with a handle 2, and a spherical contact is adopted between the fine mold bracket 4 and the fine mold adjusting flange 3, the adjusting bolt 5 and the fine mold bracket 4 are connected by precision threads, and the fine mold adjusting flange The positions on the top 3 close to the edge are respectively provided with through holes corresponding to the three adjusting bolts 5; a joint bearing 6 is arranged in each of the through holes, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com